Aluminum Alloy

As a premier aluminum alloy manufacturer and supplier, Huaxiao-Alloy specializes in precision-engineered alloys from the 1000 to 8000 series, tailored for aerospace, automotive, construction, and marine applications. Our ISO-certified production ensures compliance with ASTM, AMS, and EN standards.

Highest Quality Steel

Quick Delivery

Professional Service

Flexible payment options

aluminum coil

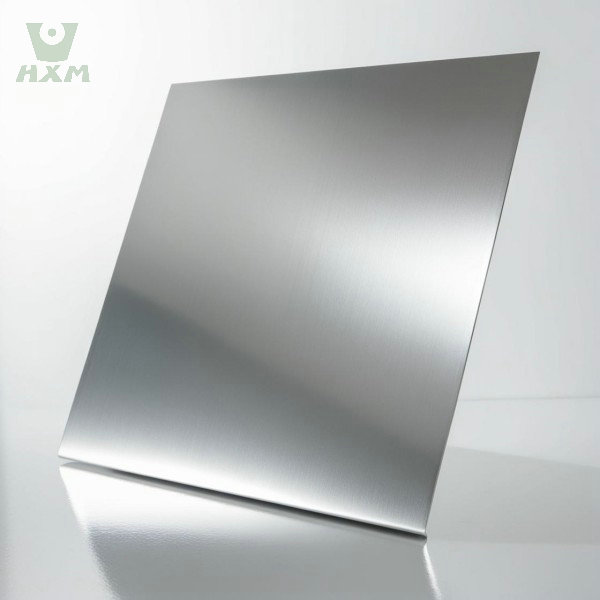

aluminum sheet

aluminum foil

aluminum circle

aluminum wire

aluminum bar

aluminum profile

aluminum tube

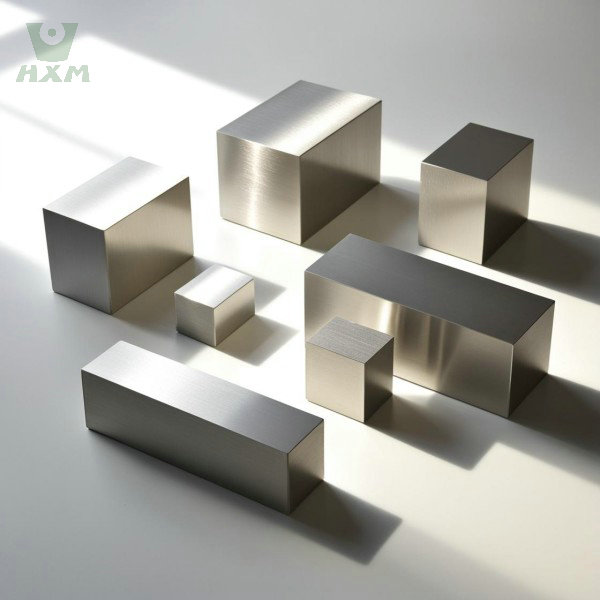

aluminum block

Aluminum Alloy Grades by Series

| Series | Primary Alloying Element | Common Grades |

|---|---|---|

| 1000 | Pure Aluminum (≥99% Al) | 1050, 1060, 1100, 1200, 1235, 1350 |

| 2000 | Copper (Cu) | 2011, 2014, 2024, 2036, 2117, 2219, 2618 |

| 3000 | Manganese (Mn) | 3003, 3004, 3005, 3105, 3203 |

| 4000 | Silicon (Si) | 4032, 4043, 4047, 4543 |

| 5000 | Magnesium (Mg) | 5005, 5052, 5083, 5086, 5154, 5454, 5754 |

| 6000 | Magnesium + Silicon (Mg + Si) | 6005, 6060, 6061, 6063, 6082, 6105, 6262 |

| 7000 | Zinc (Zn) | 7005, 7049, 7050, 7075, 7085, 7150, 7475 |

| 8000 | Iron/Lithium (Fe/Li) | 8006, 8011, 8014, 8030, 8079, 8090, 8111 |

Performance Comparison Table of Key Aluminum Alloys

| Grade | Series | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) | Typical Applications |

|---|---|---|---|---|---|---|

| 1100 | 1000 | 90–110 | 30–40 | 35–45 | 23 | Food packaging, chemical equipment |

| 2024 | 2000 | 470–510 | 290–330 | 10–12 | 120 | Aircraft structures, military hardware |

| 3003 | 3000 | 110–200 | 40–185 | 20–30 | 40 | HVAC systems, fuel tanks |

| 4032 | 4000 | 380–400 | 315–330 | 8–10 | 105 | Pistons, engine components |

| 5052 | 5000 | 210–270 | 90–215 | 12–25 | 60 | Marine components, pressure vessels |

| 6061 | 6000 | 240–310 | 210–275 | 12–17 | 95 | Structural frames, automotive parts |

| 7075 | 7000 | 510–570 | 430–500 | 10–12 | 150 | Aerospace, defense equipment |

| 8011 | 8000 | 100–150 | 35–50 | 25–30 | 30 | Foils, heat exchangers |

Key Observations

Strength:

- 2000 & 7000 series (e.g., 2024, 7075) offer the highest tensile/yield strength for aerospace and defense.

- 1000 & 8000 series (e.g., 1100, 8011) prioritize ductility and formability over strength.

Corrosion Resistance:

- 5000 series (e.g., 5052, 5083) excel in marine environments due to high magnesium content.

- 3000 series (e.g., 3003) balance moderate strength with corrosion resistance for industrial use.

Workability:

- 1000 series (e.g., 1100) and 3000 series (e.g., 3003) are ideal for deep drawing and welding.

- 6000 series (e.g., 6061) is preferred for extrusion and machining.

Thermal/Electrical Conductivity:

- 1000 series (e.g., 1060) and 8000 series (e.g., 8079) are used in electrical components and heat exchangers.

Applications & Industry-Specific Recommendations

- Aerospace: 2024 (2000 series), 7075 (7000 series).

- Automotive: 6061 (6000 series), 5083 (5000 series).

- Construction: 6063 (6000 series), 3003 (3000 series).

- Electronics: 1060 (1000 series), 8011 (8000 series).