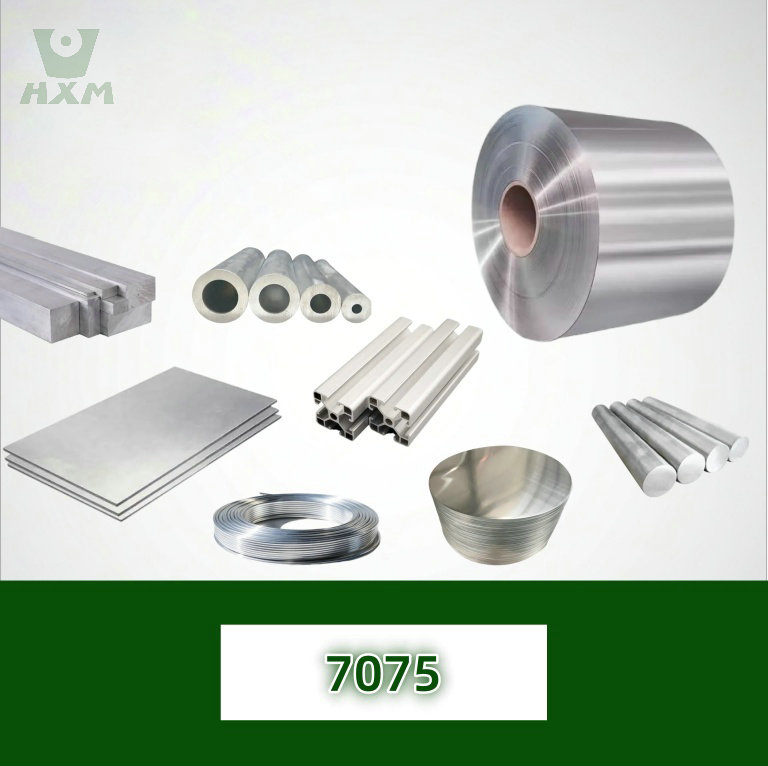

7075 Aluminum Alloy

Huaxiao-Alloy is a premier supplier and manufacturer of 7075 aluminum alloy, the industry benchmark for ultra-high-strength applications. Trusted by aerospace, defense, and automotive industries, our 7075 alloy is precision-engineered to deliver unparalleled mechanical performance. We supply plates, sheets, bars, rods, and custom profiles in T6, T651, T7351 tempers, compliant with ASTM, AMS, and MIL standards.

Key Features of 7075 Aluminum Alloy

1. Chemical Composition of 7075 Aluminum Alloy

7075 alloy achieves its exceptional strength through a precise balance of elements:

| Element | Composition (%) | Role |

|---|---|---|

| Zinc (Zn) | 5.1–6.1 | Primary strengthener via precipitation hardening |

| Magnesium (Mg) | 2.1–2.9 | Enhances tensile strength and corrosion resistance |

| Copper (Cu) | 1.2–2.0 | Improves machinability and fatigue resistance |

| Chromium (Cr) | 0.18–0.28 | Refines grain structure for toughness |

| Aluminum (Al) | Balance | Base material providing lightweight properties |

Trace elements (Fe, Si, Ti) controlled to ≤0.50%. Request full ASTM B209/B221 compliance data.

2. Physical & Mechanical Properties

of 7075 Aluminum Alloy

| Property | Value (T6 Temper) |

|---|---|

| Density | 2.81 g/cm³ |

| Melting Point | 475–635°C |

| Tensile Strength | 572 MPa |

| Yield Strength | 503 MPa |

| Elongation | 11% |

| Hardness (Brinell) | 150 HB |

| Fatigue Strength | 159 MPa (10⁷ cycles) |

| Thermal Conductivity | 130 W/m·K |

| Electrical Conductivity | 33% IACS |

3. Performance Advantages

- Ultra-High Strength: Highest strength-to-weight ratio among commercial aluminum alloys.

- Stress-Corrosion Resistance: T7351 temper for harsh environments (e.g., marine applications).

- Machinability: Excellent for CNC milling, drilling, and threading with carbide tools.

- Heat Treatable: Achieve customized properties via T6 (peak strength) or T73 (stress-relieved) tempers.

Applications of 7075 Aluminum Alloy

As a leading aerospace aluminum supplier, Huaxiao-Alloy’s 7075 alloy is used in:

- Aerospace: Wing spars, fuselage frames, and helicopter rotor components.

- Defense: Missile casings, armored vehicle parts, and artillery systems.

- Automotive: High-performance racing suspension, drive shafts, and roll cages.

- Industrial Tooling: Injection molds, jigs, and high-pressure hydraulic systems.

Why Choose Huaxiao-Alloy?

- Full Temper Range: T6, T651, T7351, and custom heat treatment options.

- Precision Processing: CNC machining, anodizing, and alodine coatings available.

- Certifications: AMS QQ-A-225/8, ASTM B209, AS9100, and ITAR compliance.

- Global Logistics: Just-in-time delivery with ISO-compliant packaging.

Huaxiao-Alloy: Your Partner for All Aluminum Series

In addition to 7075 alloy, we supply all 1000–8000 series aluminum grades, including:

- 1000 Series: 1050, 1060 (high-purity conductive alloys)

- 2000 Series: 2024, 2219 (aircraft structural alloys)

- 6000 Series: 6061, 6082 (architectural extrusions)

- 7000 Series: 7050, 7046 (military/aerospace grades)

- 8000 Series: 8011, 8079 (packaging foils)

Request a Quote for Any Aluminum Grade!

A: 7075-T6 offers peak strength (572 MPa tensile) but lower stress-corrosion resistance. 7075-T7351 sacrifices ~10% strength for superior corrosion resistance in harsh environments.

A: Yes, but it requires specialized techniques (e.g., friction-stir welding). Arc welding may reduce strength due to thermal cracking risks.

A: 7075 has 2x higher strength than 6061-T6 but lower corrosion resistance and weldability. Use 6061 for general-purpose structural applications.

A: Anodizing (Type III), alodine coatings, or powder coating to enhance corrosion resistance.

A: MOQ starts at 500 kg for standard profiles. Custom tempers/quantities available for OEMs.

A: Yes, all orders include Mill Test Reports (MTRs) with chemical, mechanical, and thermal data.