Among various alloys and metals, Monel, a nickel-copper alloy, stands out for its exceptional resistance to corrosion, making it a highly sought-after material in demanding industrial and marine applications. In this article, we will delve deeper into the anti-corrosive properties of Monel, its underlying mechanisms, and the factors that influence its corrosion resistance.

Exploring the Anti-Corrosive Properties of Monel

1. What is Monel?

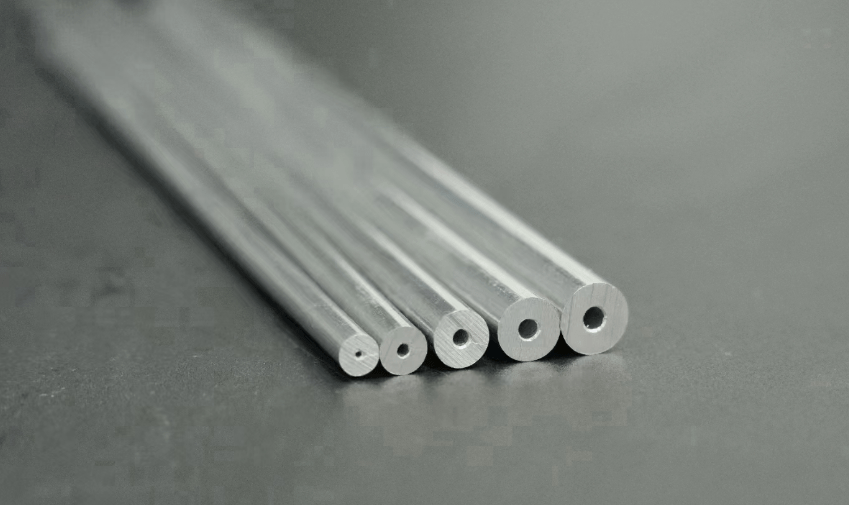

Monel, first developed in the early 20th century, is a nickel-copper alloy that typically contains between 60% and 70% nickel. Its composition can also include small amounts of other elements such as iron, manganese, and silicon to enhance its mechanical properties. The alloy’s name derives from the Monroe Doctrine, a policy statement issued by the United States in 1823, symbolizing its durability and resilience.

2. Anti-Corrosive Properties of Monel

Monel’s resistance to corrosion is one of its most remarkable features. This alloy’s ability to withstand corrosive environments is due to several factors:

- Passive Oxide Layer Formation: When exposed to oxidizing environments, the surface of Monel forms a thin, adherent oxide layer. This layer acts as a barrier, preventing further corrosion by blocking the ingress of corrosive agents.

- High Nickel Content: Nickel, being a noble metal, has inherent corrosion resistance. The high nickel content in Monel alloys contributes significantly to its resistance to corrosion, especially in acidic environments.

- Low Electrochemical Activity: Monel exhibits low electrochemical activity, making it less susceptible to galvanic corrosion when in contact with other metals. This is a critical advantage in multi-metal environments where corrosion can be accelerated due to galvanic interactions.

- Resistance to Chloride Stress Corrosion Cracking: Monel demonstrates excellent resistance to chloride stress corrosion cracking, a common problem in many alloys exposed to saltwater or chloride-rich environments.

3. Applications of Monel

The anti-corrosive properties of Monel have found widespread applications in various industries:

- Marine Industry: Monel is widely used in the marine industry due to its resistance to saltwater corrosion. It is commonly employed in propellers, shafts, and other components exposed to harsh marine environments.

- Chemical Processing: In the chemical processing industry, Monel is used in equipment and piping systems that handle corrosive chemicals.

- Oil and Gas Industry: Oil and gas exploration often involves exposure to corrosive environments, and Monel’s corrosion resistance makes it a suitable material for components such as valves and pumps.

- Nuclear Industry: Monel’s resistance to radiation-induced corrosion makes it a preferred material in the nuclear industry, particularly for components in reactors and radioactive waste storage systems.

Conclusion

Monel, with its exceptional anti-corrosive properties, has become a reliable material choice for applications in demanding environments. Its unique combination of nickel and copper, along with its ability to form a protective oxide layer, contribute significantly to its corrosion resistance. Its widespread use in the marine, chemical processing, oil and gas, and nuclear industries underscores its value and reliability. As materials technology continues to evolve, Monel’s position as a premier corrosion-resistant alloy is likely to remain secure.

Thank you for reading our article and we hope it can help you to have a better understanding of the anti-corrosive properties of Monel. If you are looking for Monel Alloy suppliers online now, please don’t hesitate to contact Huaxiao Alloy.

As a leading supplier of high-temperature alloys from Shanghai China, Huaxiao Alloy provides customers with high-quality Monel K500 and Monel 400, Inconel 602 alloy, Hastelloy S Alloy, Inconel Alloy 600, Inconel Alloy 601, Inconel 625 UNS N06625, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), and Hastelloy C-2000 at a very competitive price.