In our daily lives, Monel fasteners offer a range of benefits that make them stand out from other fastener materials. In this article, we will delve into the key benefits of using Monel fasteners, discussing their properties, applications, and the advantages they bring to various industries.

7 Key Benefits of Using Monel Fasteners

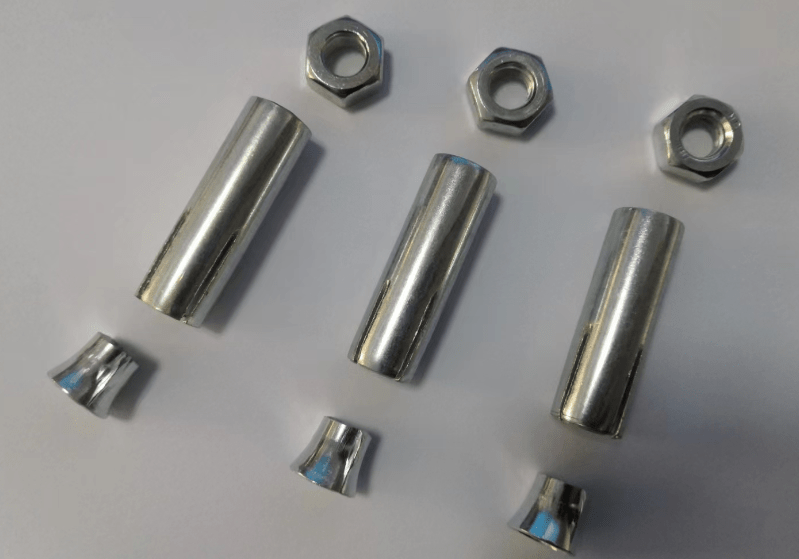

Monel is a nickel-copper alloy that is renowned for its strength, corrosion resistance, and ductility. It was first developed in the early 20th century and has since found widespread use in various industries, particularly in marine and chemical processing applications. The combination of nickel and copper in Monel alloy confers excellent resistance to corrosion, even in harsh environments such as saltwater and acidic conditions.

Here are the key benefits of using Monel fasteners:

- Excellent Corrosion Resistance: Monel’s resistance to corrosion is one of its most noteworthy features. It can withstand exposure to saltwater, acids, alkalis, and other corrosive agents without succumbing to damage. This makes it an ideal material for fasteners used in marine applications, chemical processing plants, and other environments where corrosion is a concern.

- High Strength and Ductility: Monel alloys possess high strength and ductility, which means they can withstand significant loads without breaking or cracking. They can be easily formed and shaped, making them suitable for a wide range of applications.

- Excellent Electrical Conductivity: Monel is a good conductor of electricity, which makes it useful in electrical applications where fasteners need to conduct current. This property is particularly beneficial in the energy and electronics industries.

- Low Magnetic Permeability: Unlike some other metals, Monel is non-magnetic, meaning it does not respond to magnetic fields. This property is advantageous in applications where magnetic interference could be problematic, such as in medical devices or precision instrumentation.

- Easy to Fabricate and Machine: Monel can be easily fabricated and machined into various shapes and sizes, making it a versatile material for fasteners. This ease of processing allows for cost-effective manufacturing and customization.

- Good Weldability: Monel can be easily welded using various welding techniques, allowing for easy repairs and modifications. This weldability is beneficial in applications where fasteners may need to be repaired or replaced.

- Long Service Life: Due to its corrosion resistance, strength, and ductility, Monel fasteners have a long service life, reducing the need for frequent replacements. This contributes to cost savings and overall efficiency.

Conclusion

In summary, Monel fasteners offer a range of benefits that make them an excellent choice for various applications. Their corrosion resistance, strength, ductility, electrical conductivity, low magnetic permeability, ease of fabrication and machining, good weldability, and long service life all contribute to their widespread use in industries such as marine, chemical processing, energy, electronics, and more.

Thank you for reading our article and we hope it can help you to have a better understanding of the key benefits of using Monel fasteners. If you are looking for Monel alloy suppliers online now, we would advise you to contact Huaxiao Alloy.

As a leading supplier of high-temperature alloys from Shanghai China, Huaxiao Alloy provides customers with high-quality Monel 400, Monel K-500, Inconel 602 alloy, Hastelloy S Alloy, Inconel Alloy 600, Inconel Alloy 601, Inconel 625 UNS N06625, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), and Hastelloy C-2000 at a very competitive price.