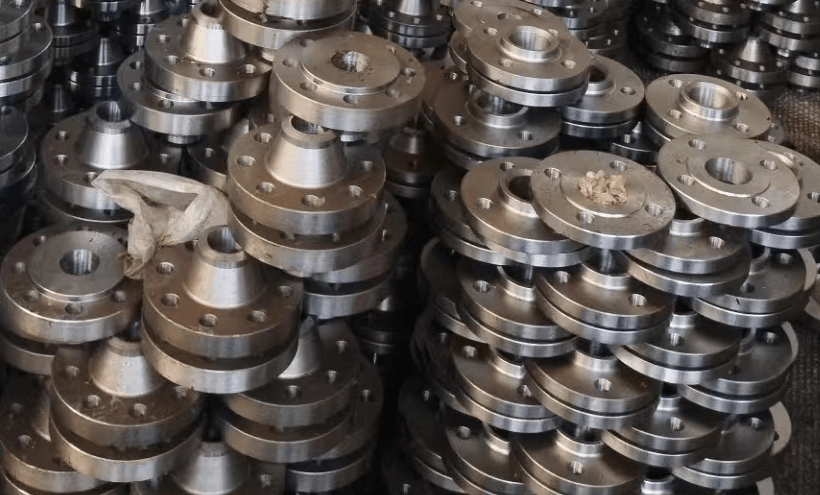

Inconel 718, a superalloy in the nickel–chromium family, has been a staple in high-performance applications for decades. Its unique composition and properties have made it a preferred material for a wide range of industries, particularly in the form of flanges. In this comprehensive article, we delve into the intricacies of Inconel 718 flanges, discussing their composition, properties, and the diverse applications where they excel.

Inconel 718 Flanges – Composition, Properties and Uses

Composition of Inconel 718 Flanges

The composition of Inconel 718 flanges is tailored to provide exceptional strength, corrosion resistance, and high-temperature performance. The alloy is primarily composed of nickel, chromium, and iron, with smaller amounts of other elements such as titanium, aluminum, and molybdenum.

Nickel, being the major constituent, accounts for approximately 50-55% of the alloy’s composition. It confers excellent ductility, toughness, and resistance to oxidation at elevated temperatures. Chromium, present at about 17-21%, enhances the corrosion resistance of the alloy, particularly against oxidizing environments. Iron, making up about 20-25%, adds to the alloy’s strength and stability.

The addition of titanium and aluminum, in the range of 2.8-3.3% and 0.65-1.15% respectively, acts as a strengthening agent. These elements form precipitates within the alloy matrix, improving its mechanical properties, particularly at high temperatures. Molybdenum, present in smaller quantities (up to 0.3%), further enhances the corrosion resistance of Inconel 718, particularly against reducing environments.

Properties of Inconel 718 Flanges

- High-Temperature Performance: Inconel 718 flanges maintain their mechanical properties at temperatures up to 1300°F (704°C), making them suitable for use in high-temperature applications such as jet engines and gas turbines.

- Excellent Corrosion Resistance: The alloy’s composition confers resistance to a wide range of corrosive environments, including those containing oxygen, sulfur, and chloride ions. This makes Inconel 718 flanges ideal for use in chemical processing equipment, marine applications, and other demanding environments.

- Strength and Ductility: Inconel 718 combines high strength with good ductility, allowing it to be formed and machined into complex shapes without sacrificing its mechanical properties.

- Weldability: The alloy can be easily welded using various techniques, making it suitable for applications that require welding of flanges to other components.

- Low Coefficient of Thermal Expansion: Inconel 718 has a relatively low coefficient of thermal expansion, reducing the risk of thermal stress and failure in high-temperature applications.

Uses of Inconel 718 Flanges

The unique combination of properties exhibited by Inconel 718 flanges makes them ideal for a diverse range of applications across various industries. Some of the primary uses of Inconel 718 flanges include:

- Aerospace Industry: Due to its high-temperature performance and corrosion resistance, Inconel 718 flanges are widely used in the aerospace industry, particularly in jet engines, gas turbines, and rocket propulsion systems.

- Oil and Gas Industry: In harsh environments encountered in oil and gas exploration and production, Inconel 718 flanges are used in pipelines, refining equipment, and other critical components where resistance to corrosion and high temperatures is crucial.

- Chemical Processing Industry: The alloy’s resistance to corrosion in various chemical environments makes it suitable for use in flanges for chemical reactors, storage tanks, and piping systems.

- Power Generation: Inconel 718 flanges are employed in power generation equipment such as gas turbines and boilers, where they can withstand the high temperatures and corrosive environments encountered during operation.

Conclusion

In conclusion, Inconel 718 flanges, with their unique composition and exceptional properties, are an invaluable material for a wide range of applications. Their high-temperature performance, corrosion resistance, strength, and ductility make them a preferred choice for flanges in the aerospace, oil and gas, chemical processing, and power generation industries.

Thank you for reading our article and we hope you’ve enjoyed it. If you are looking for Inconel 718 flange suppliers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of high-temperature alloys from Shanghai China, Huaxiao Alloy provides customers with high-quality Inconel 718 Alloy, Monel 400, Monel K500, Inconel 602 alloy, Hastelloy S Alloy, Inconel Alloy 600, Inconel Alloy 601, Inconel 625 UNS N06625, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), and Hastelloy C-2000 at a very competitive price.