AMS 5542 Inconel alloy is a nickel-based superalloy that exhibits exceptional properties in high-temperature environments. It is widely utilized in various industrial applications where resistance to corrosion, high strength, and excellent thermal stability are paramount. This article delves into the composition, properties, and uses of AMS 5542 Inconel alloy.

AMS 5542 INCONEL ALLOY – Composition, Properties, and Uses

Composition of AMS 5542 Inconel Alloy

AMS 5542 Inconel alloy is primarily composed of nickel, chromium, and iron. Nickel, being the primary constituent, accounts for a significant portion of the alloy’s weight, typically ranging between 50% and 60%. Chromium is added to enhance corrosion resistance, particularly against oxidizing environments. Iron, while present in a smaller quantity, contributes to the alloy’s mechanical strength.

In addition to these primary elements, AMS 5542 Inconel alloy contains smaller amounts of other metals such as molybdenum, titanium, aluminum, and carbon. Molybdenum improves the alloy’s resistance to corrosion and creep, while titanium and aluminum contribute to the formation of protective oxide layers. Carbon, in its trace amounts, helps refine the grain structure and enhance the alloy’s mechanical properties.

Properties of AMS 5542 Inconel Alloy

The properties of AMS 5542 Inconel are truly remarkable, making it a material of choice for numerous demanding applications. Here are some of its key properties:

- High-Temperature Strength and Stability: AMS 5542 Inconel alloy maintains its strength and ductility even at temperatures well above 1000°C. This makes it suitable for use in engines, turbines, and other high-temperature components.

- Excellent Corrosion Resistance: The chromium content in the alloy provides excellent resistance to oxidation and corrosion, even in aggressive environments like saltwater or high-pressure steam.

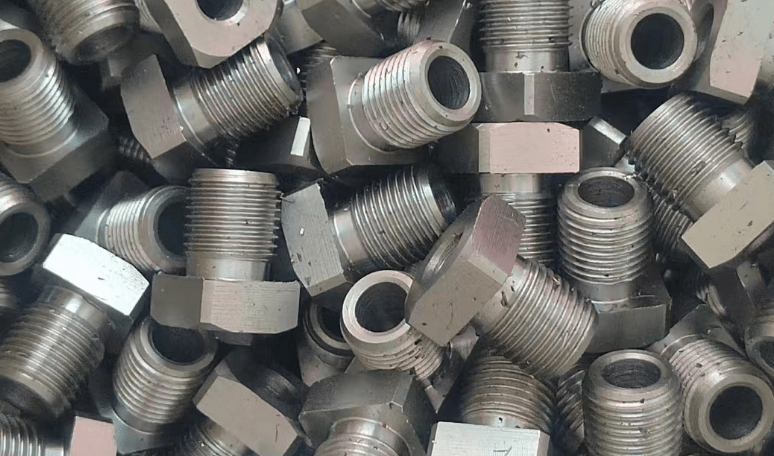

- Good Fabrication Characteristics: AMS 5542 Inconel alloy can be easily welded, forged, and machined, allowing for the production of complex shapes and components.

- Low Thermal Expansion Coefficient: Compared to other metals, Inconel alloy exhibits a relatively low thermal expansion coefficient, which is beneficial in maintaining dimensional stability under varying temperature conditions.

- Good Fatigue Resistance: The alloy’s resistance to fatigue failure, particularly under cyclic loading conditions, is exceptional. This property is crucial in components that undergo repeated stress cycles, such as turbine blades.

Uses of AMS 5542 Inconel Alloy

Due to its exceptional properties, AMS 5542 Inconel finds widespread application in various industries:

- Aerospace Industry: Inconel alloy is a critical material in the aerospace industry, where components must perform reliably under extreme temperatures and corrosive environments. It is used in jet engine turbines, combustion chambers, and exhaust systems.

- Chemical Processing: The alloy’s corrosion resistance makes it suitable for use in chemical processing equipment, such as reactors, heat exchangers, and piping systems that handle corrosive chemicals.

- Marine Applications: In the marine industry, AMS 5542 Inconel alloy is often employed in shipbuilding, particularly in components that are exposed to saltwater and high humidity, such as propellers and shafts.

- Power Generation: Turbines and other components in power plants, especially those operating at high temperatures, often utilize Inconel alloy for its superior high-temperature performance.

- Oil and Gas Industry: The alloy’s ability to withstand high temperatures and corrosion makes it suitable for use in drilling equipment, valves, and pipelines in the oil and gas industry.

- Automotive Industry: In the automotive sector, Inconel alloy is used in exhaust systems and turbocharger components, where its high-temperature stability and corrosion resistance are vital.

Conclusion

AMS 5542 Inconel, with its unique composition and exceptional properties, has become a material of choice for numerous industrial applications. Its ability to maintain strength and stability at high temperatures, coupled with its resistance to corrosion, makes it invaluable in demanding environments.

Thank you for reading our article and we hope you’ve enjoyed it. If you are looking for AMS 5542 INCONEL ALLOY supplier and manufacturer online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Inconel Alloy products from Shanghai China, Huaxiao Alloy offers customers high-quality AMS 5542 INCONEL ALLOY, AMS 5798 Inconel alloy, AMS 5536 Inconel Alloy, Inconel 713C alloy, Inconel® 686 alloy, Inconel 600, Inconel 825, Inconel 601, and Inconel 718 at a very competitive price.