Monel

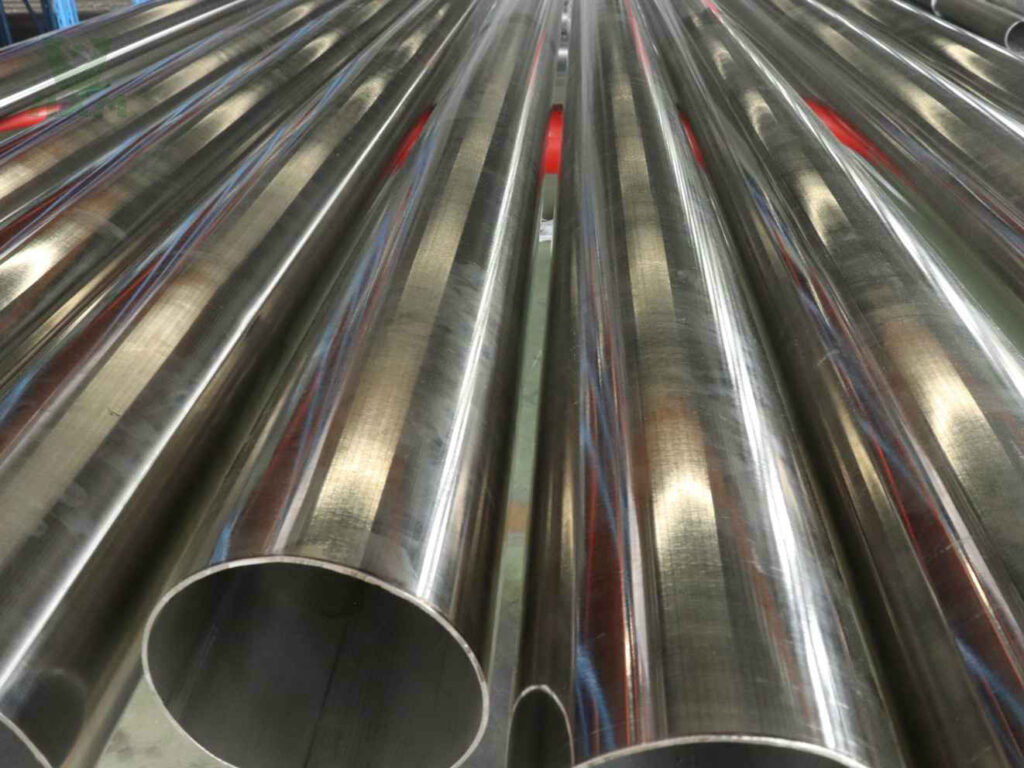

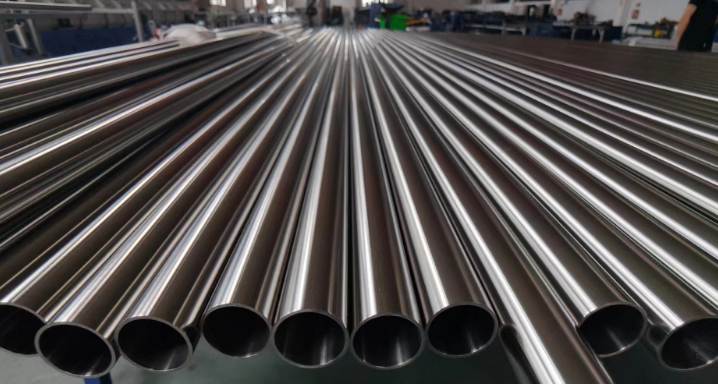

Monel alloys are specialty alloys known for their excellent corrosion resistance and mechanical properties. Compared to other alloys, Monel metals have significant differences in composition, microstructure and application areas.

Its uniqueness lies in the presence of elements such as copper and nickel, which are carefully proportioned to provide excellent corrosion resistance for highly corrosive environments such as offshore engineering, petrochemical and nuclear industries.

In addition, Monel metals also have good machinability, weldability and high-temperature performance, making them an ideal engineering material and providing reliable support for the development of industrial fields.

Grades of Monel Metal

monel Product standards datasheet

| Grades | Plates/Strips (ASTM/AMS) | Seamless Pipe (ASTM/AMS) | Bars/Wires/Round Billets (ASTM/AMS) | Forgings/Flanges/Valves (ASTM/AMS) |

|---|---|---|---|---|

| Monel 400 | ASTM B127 | ASTM B165 | ASTM B164 | ASTM B564 |

| Monel K-500 | ASTM B865, AMS 4676 | ASTM B127 | ASTM B865 | ASTM B564 |

Advantages of Monel Metal

Monel alloys have several significant differences compared to other specialty alloys:

1. Unique corrosion resistance mechanism:

The corrosion resistance of Monel alloys is not only derived from their composition, but also from their microstructure. Trace elements in the alloy form a protective oxide film that further enhances its corrosion resistance.

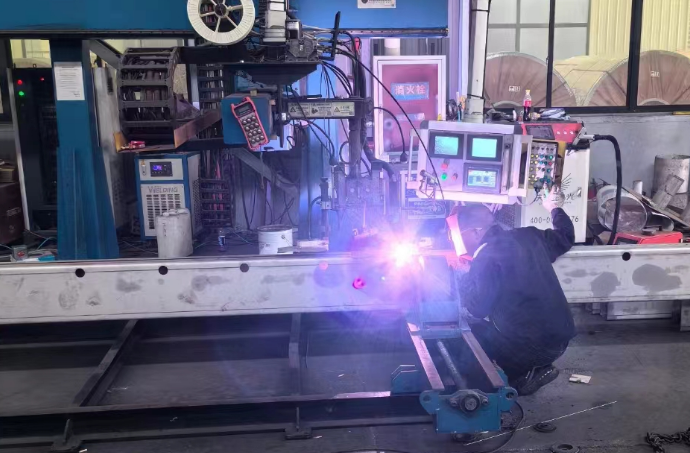

2. Good welding performance:

Due to its special composition and microstructure, monel alloy has excellent welding performance. This enables efficient and reliable connections during fabrication.

3. Stability at high temperatures:

Compared with other alloys, Monel alloys maintain excellent mechanical properties and corrosion resistance in high temperature environments. This gives them a unique advantage in high-temperature applications.

4. Biocompatibility:

Monel alloys have good biocompatibility, making them widely used in medical devices and implants.

5. Diversified application areas:

In addition to the traditional petrochemical and marine engineering fields, monel alloys are also widely used in electric power, pharmaceutical and food processing industries, due to their excellent performance and reliability.

In summary, Monel alloys offer unique advantages in terms of corrosion resistance mechanisms, welding properties, high temperature stability, biocompatibility and application versatility, making them an excellent engineering material.

FAQs

Monel metal is a special type of alloy known for its excellent corrosion resistance and good mechanical properties. It consists mainly of elements such as nickel and copper, which are carefully proportioned to give it excellent corrosion resistance.Monel metal has a wide range of applications in many fields, such as marine engineering, petrochemical and nuclear industries. It has good machinability, weldability and high temperature properties, making it an ideal engineering material. Due to its stability and reliability, Monel metal is widely used in key equipment and important projects, providing reliable support for the development of industrial fields.

Monel 400 and Monel K500 are two common monel alloys that are both composed of nickel and copper, but with different compositions; Monel 400 contains about 67% nickel and 33% copper, while Monel K500 contains about 70% nickel and 30% copper. In addition, Monel K500 contains small amounts of iron, manganese, carbon, silicon and cobalt.

Despite their different compositions, both Monel 400 and Monel K500 exhibit excellent corrosion resistance, high strength, good workability, and excellent wear resistance. They can work in a variety of harsh environments, including seawater, acidic environments, and alkaline environments.

However, there are some differences between the two in terms of specific applications. Due to its higher nickel content, Monel K500 has higher strength and hardness, as well as better heat corrosion resistance and long-term structural stability. This means that it is more suitable for applications that require high strength and wear resistance, such as bearings, pump parts, marine parts, etc.

On the other hand, Monel 400 has better machinability, making it more suitable for use when operations such as welding, cold working and bending are required.

Overall, both Monel 400 and Monel K500 are excellent Monel alloys that can be selected for use according to specific needs.