In the process of seawater desalination, salt and chlorifde ions in seawater will cause corrosion to metal materials, which poses severe challenges to the performance of the materials. Hastelloy is widely used in seawater desalination equipment due to its excellent high corrosion resistance. In this article, we will introduce the application of Hastelloy in seawater desalination equipment.

Application of Hastelloy in Seawater Desalination Equipment:

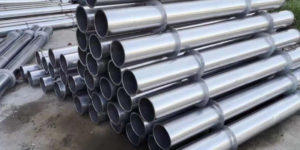

First, application in piping systems. In the process of seawater desalination, pipeline equipment has to be in a highly corrosive environment such as seawater for a long time, and it is very easy to chemically react with corrosive media such as chloride ions and acid and alkali ions in seawater, causing local corrosion phenomena, which in turn leads to equipment damage and leakage. This requires equipment materials to have excellent corrosion resistance. The pipeline system made of Hastelloy has good corrosion resistance and can resist damage to the inner wall of the pipeline caused by corrosive substances, which plays an important role in ensuring the long-term stable operation of the equipment.

Secondly, its application in heat exchangers. Seawater desalination is a vast and complex project. In addition to requiring excellent corrosion resistance, the equipment also needs to have good high temperature resistance. Since the seawater desalination device will generate a large amount of high temperature during operation, this requires the equipment to maintain stable performance in a high-temperature environment. Hastelloy has good high-temperature resistance. Heat exchanger equipment made of Hastelloy, in addition to being resistant to seawater corrosion, can also adapt to high-temperature and high-pressure working environments.

Furthermore, application on processing equipment. In the seawater desalination process, high wear-resistant seawater desalination treatment equipment is very important to the seawater desalination project. Hastelloy is particularly popular in the manufacturing of treatment equipment such as filters and water quality conditioning devices due to its excellent wear resistance. This is mainly due to the excellent wear resistance of Hastelloy, which can reduce equipment wear caused by high-speed flowing seawater media, which not only reduces maintenance costs, but also increases the service life of the equipment.

In addition, application in evaporation equipment. Compared with traditional desalination technology, solar desalination technology has gradually attracted attention because it does not consume conventional energy, is pollution-free, and has high purity of fresh water. Hastelloy is an ideal material for making evaporators because of its good light-to-heat conversion performance, which can improve evaporation efficiency and solve the problem of salt accumulation.

Conclusion

In short, the excellent performance of Hastelloy makes it play an important role in seawater desalination equipment. It not only improves the reliability and service life of the equipment, but also ensures the stable and efficient operation of the seawater desalination process. However, the cost of Hastelloy is relatively high, which increases the cost of seawater desalination equipment. Therefore, in practical applications, its performance, cost and other factors need to be comprehensively considered to achieve the best economic benefits and engineering effects.

Why Choose Huaxiao Alloy?

Thank you for reading our article and we hope it can help you to have a better understanding of the application of Hastelloy in seawater desalination equipment. If you are looking for Hastelloy alloy suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Hastelloy alloy from Shanghai China, Huaxiao Alloy offers customers high-quality Hastelloy C-22 and Hastelloy X at a very competitive price.