With the continuous development of the petroleum industry, the performance requirements for petroleum equipment are also constantly increasing. As an important material in petroleum equipment, Monel alloy is widely used in the petroleum industry because of its excellent strength, corrosion resistance and mechanical strength. This article will introduce in detail the application of Monel alloy in the petroleum industry.

Application of Monel Alloy in the Petroleum Industry:

First, application in oil extraction equipment. Most of the world’s petroleum resources are buried thousands of meters below the surface. During the mining process, drilling and other mining equipment must operate in extreme underground temperatures, pressures, and corrosive substances, which poses challenges to the performance of mining equipment. meet extremely stringent requirements. Monel alloy has excellent mechanical strength and corrosion resistance. It can not only withstand high-frequency mechanical vibrations during the mining process, but also effectively resist the erosion of hydrocarbons, sulfur, oxygen and nitrogen compounds in crude oil. It is an ideal material for manufacturing drill pipes, Ideal material for mining equipment such as drill bits.

Secondly, application in oil production equipment. In the process of oil extraction, oil extraction equipment such as pumping units and electric submersible pumps need to be used to reciprocate to lift underground crude oil to the surface. The pumps and valves in these equipment need to operate reliably in a corrosion-resistant environment. Components such as pumps and valves made of Monel alloy can maintain stability in highly corrosive media such as oil, ensuring the service life of oil production equipment.

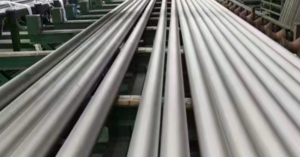

Furthermore, application in transportation equipment. After oil is extracted from the ground, pipelines are needed to transport the oil over long distances. During this process, a large amount of corrosive substances in the oil will adhere to the surface of the pipelines, which in the long run may lead to pipeline rupture and oil leakage. question. Monel alloy pipelines can effectively resist corrosion, reduce safety risks caused by oil leaks, and provide guarantee for the safe transportation of oil.

In addition, application in storage devices. During the storage process of oil, a large amount of oil will not only exert huge pressure on the inner wall of the oil storage tank, but also cause the corrosive substances in the oil to corrode the inner wall of the oil storage tank, thus causing huge safety hazards. The excellent corrosion resistance of Monel alloy makes up for this potential safety hazard during oil storage.

Summary

In short, Monel alloy is widely used in the petroleum industry due to its excellent properties. It is present in everything from mining equipment to oil extraction equipment to transportation equipment and storage equipment. Although the price and cost of Monel alloy are relatively high, the application of Monel alloy is of great significance to ensure the safety, stability and long-term operation of equipment, reduce equipment failure and maintenance costs due to corrosion, and improve oil production efficiency.

Why Choose Huaxiao Alloy?

Thank you for reading our article and we hope it can help you to have a better understanding of the application of Monel alloy in the petroleum industry. If you are looking for Monel alloy suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel alloys from Shanghai China, Huaxiao Alloy offers customers high-quality Monel alloy products such as Monel 400 and Monel K500 at a very competitive price.