What is pickling plate?

- July 21, 2024

- 9:46 pm

- 1184

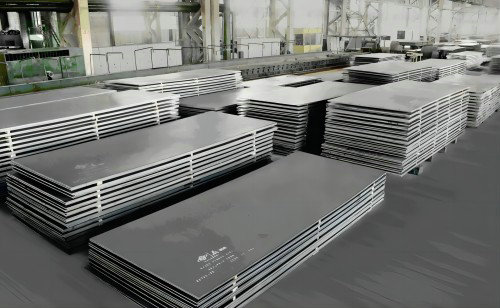

Pickling Plate is an intermediate product with high quality hot rolled sheet as raw material, after removing the oxidized layer by pickling unit, cutting edge and finishing, the surface quality and usage requirements are between hot rolled plate and cold rolled plate, it is an ideal substitute product for some hot rolled plate and cold rolled plate, and it is an ideal substitute product for some hot rolled plate and cold rolled plate.

features of pickling plate

1.Good surface quality, because the hot rolled pickling plate removes the surface iron oxide skin, improve the surface quality of steel, easy to weld, oil and paint.

2.High dimensional accuracy, after leveling, it can make certain changes in the plate shape, thus reducing the deviation of unevenness.

3.Improve the surface finish and enhance the appearance.

4.It can reduce the environmental pollution caused by users’ decentralized pickling.

5.Compared with cold rolled plate, the advantage of pickling plate is to ensure the surface quality, with the requirements of the premise, so that the user effectively reduce the procurement cost.

The production process of pickled plate

Hot Rolled Steel Plate: Firstly, hot rolled steel plate is produced, which is the base material for pickling plate.

Pickling treatment: The hot rolled steel plate is immersed into the pickling tank to remove the oxide skin and impurities on the surface through chemical reaction.

Cleaning and Neutralization: After pickling, the steel plate needs to be cleaned and neutralized to remove residual acid and other chemicals.

Drying and surface treatment: After cleaning, the steel plate is dried and further surface treatment, such as oiling and rust prevention, is carried out as required.

Common Applications for Pickled Plates

Automotive Manufacturing

Body and Chassis:

- Pickling plates are used in the manufacturing of automotive body panels and chassis components. Their smooth surface is advantageous for painting and corrosion protection.

Structural and Reinforcement Components:

- They are also utilized in making frames, beams, and other parts that require high strength and good formability.

Home Appliance Manufacturing

Shells and Structural Parts:

- Pickling plates are used in producing the outer shells and internal structural components of appliances such as refrigerators, washing machines, and air conditioners due to their high surface quality, which facilitates painting and processing.

Internal Components:

- Examples include internal supports, trays, and other internal parts of home appliances.

Metal Furniture

Desks, Chairs, and Cabinets:

- Pickling plates are employed in the production of office desks, chairs, file cabinets, and storage cabinets because their smooth surface is easy to paint and has good corrosion resistance.

Display Racks and Shelves:

- They are also used in making store display racks and warehouse shelves.

Hardware Products

Tools and Equipment:

- Pickling plates are used for manufacturing the outer shells and structural components of various tools and equipment, such as hand trucks and toolboxes.

Parts:

- Examples include hardware parts for doors and windows, as well as building connectors.

Machinery Manufacturing

Machine Shells and Guards:

- Pickling plates are used in producing the shells and guards of machinery, benefiting from their high surface quality, corrosion resistance, and ease of maintenance.

Structural and Support Parts:

- They are used to manufacture structural supports and other critical parts of machinery.

Construction and Decoration

Decorative Panels:

- Pickling plates are used to manufacture interior decorative panels and ceilings.

Structural Steel Plates:

- They are used in building structures, such as wall panels and roof panels.

Pipelines and Containers

Pipeline Systems:

- Pickling plates are used in manufacturing pipes and their fittings due to their good corrosion resistance.

Tanks and Containers:

- They are employed in making the shells and internal structures of various tanks and containers.

If you found this article good, feel free to share it on your other social media platforms.

Pickling material refers to metal that has undergone a pickling process. This process involves treating the metal with acid solutions to remove impurities such as scale, rust, and oxides that form on the surface during manufacturing processes like hot rolling, welding, and heat treatment. The primary materials subjected to pickling are steel and stainless steel, but the process can be used for other metals as well.

Pickling stainless steel means treating stainless steel with a specific acid solution, usually a combination of nitric acid (HNO3) and hydrofluoric acid (HF). This treatment removes contaminants, discoloration, and surface oxides that form during manufacturing processes such as welding and heat treatment. The result is a clean, smooth, and often more corrosion-resistant surface.

Pickling serves several important functions for metal:

- Removes Surface Oxides and Scale: It eliminates oxides, scale, and rust that form during hot working processes.

- Improves Surface Quality: It results in a cleaner and smoother surface, enhancing the metal’s appearance and suitability for subsequent processing such as painting or plating.

- Enhances Corrosion Resistance: For stainless steel, pickling removes contaminants that can lead to localized corrosion, thereby improving the overall corrosion resistance of the metal.

- Prepares for Further Processing: A clean surface is essential for further processing steps such as coating, painting, or welding, ensuring better adhesion and quality.

The term “pickling” is derived from the food preservation process where vegetables are soaked in acidic brine. Similarly, in metallurgy, steel is “soaked” in acid solutions to clean its surface. The analogy with food pickling highlights the use of acid to achieve the desired cleaning effect.

The purpose of pickling is to clean metal surfaces by removing impurities such as scale, rust, and oxides. This cleaning process serves several key objectives:

- Surface Preparation: Ensures the metal surface is clean and smooth for further processing like coating, painting, or welding.

- Corrosion Resistance: Enhances the metal’s resistance to corrosion by removing contaminants that can cause localized corrosion, particularly in stainless steel.

- Improved Aesthetics: Results in a visually appealing surface, free from discoloration and imperfections.

- Improved Mechanical Properties: By removing surface defects, pickling can improve the metal’s performance in its intended application.