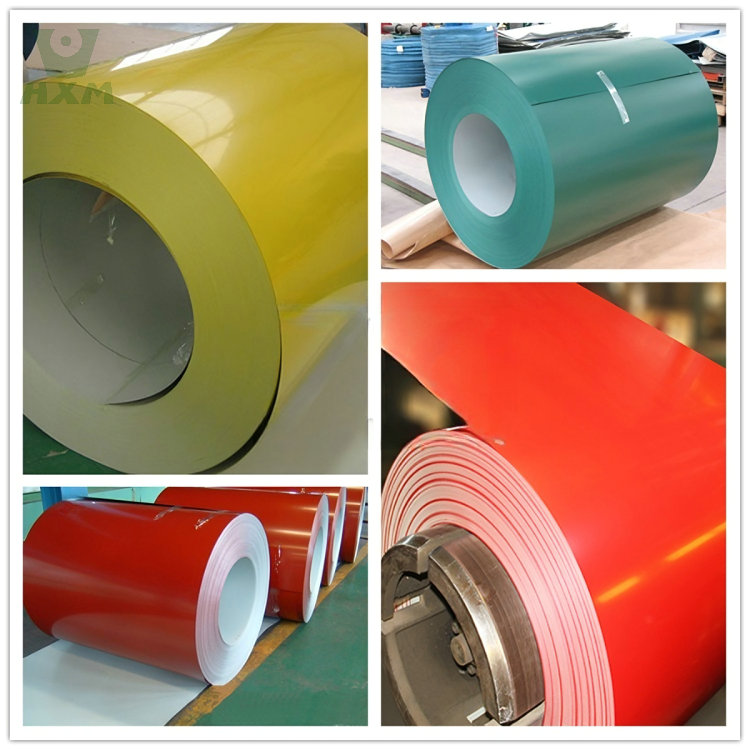

What is PPGI coil?

- July 29, 2024

- 5:54 pm

- 2137

PPGI coil is an abbreviation for “pre-painted galvanized steel coil”.

Color coated sheet basic concept: Cold-Strip Steel Rolling Mill, zinc-coated steel strips (electro-galvanized and hot-dip galvanized) as a substrate in a continuous unit, after the surface pretreatment (degreasing and chemical treatment), with the method of roller coating, coated with one or more layers of liquid paint, baked and cooled sheets that is coated steel sheets. Now there are back (bottom) paint and top (front) paint coating, generally one layer of back paint and two layers of top paint in China, and two layers of back paint in foreign business. Because the coating can have a variety of different colors, it is customary to call the coated steel sheets color coated steel sheets.

PPGI steel sheet is widely used, with no pollution, excellent weather resistance, corrosion resistance, high processing and other characteristics. PPGI steel sheets are widely used in construction, home appliances, transportation, packaging, machining, interior decoration, medical care, automotive industry and so on.

Use of PPGI coil

PPGI coil is a product made of hot-dip galvanized sheet, hot-dip alumina-zinc sheet, electro-galvanized sheet, etc., after surface pretreatment (chemical degreasing and chemical conversion treatment), one or several layers of organic coatings are applied to the surface, which are subsequently baked and cured. Its main uses are:

(1) With light weight, beautiful and good anti-corrosion properties, and can be directly processed, it is mainly used in advertising, construction, home appliance industry, electrical appliances industry, furniture industry and transportation industry.

(2) PPGI coil coating according to the use of different environments to choose the appropriate resin, such as polyester silicone modified polyester, polyvinyl chloride plastisol, polyvinyl chloride and so on. Users can choose according to the use.

Coating structure type of PPGI coil

2/1: the upper surface is coated twice, the lower surface is coated once and baked twice.

2/1M: upper and lower surfaces are coated twice and baked once.

2/2: upper and lower surfaces are coated twice and baked twice.

v Usage of different coating structures:

2/1: The corrosion resistance and scratch resistance of single layer of backside paint is poor, but it has good adhesion and is mainly used in sandwich panels;

2/1M: The backside paint has better corrosion resistance, scratch resistance and process molding, but has good adhesion, and is applied to single-layer pressboards and sandwich panels.

2/2: double-layer back paint corrosion resistance, scratch resistance and processing molding better, most for single-layer pressure plate, but its bonding is bad, should not be used for sandwich panels.

Material of PPGI coil

1.Substrate: Cold rolled sheet Aluminum zinc plated sheet Galvanized sheet Aluminum plate

2.Coating process: single-sided, double-sided, two-coated, three-coated, printed, laminated and embossed.

3.Color: single color wood grain, marble grain, brick grain, camouflage, etc., etc., etc.

4.Coating materials: Y grease paint X olefin resin paint T natural resin paint B acrylic paint F phenolic resin paint Z polyester paint L asphalt paint H epoxy resin paint C alkyd resin paint S polyurethane paint A amino acid resin paint W elemental organosilicone paint Q nitro paint J rubber paint M cellulose paint E other G vinyl perchlorate paint.

Product Characteristics

1.Good durability, corrosion resistance and longer life compared with galvanized steel sheets;

2.Good heat resistance, less discoloration at high temperature compared with galvanized steel sheets;

3.It has good heat reflectivity;

4.It has similar processing performance and spraying performance as galvanized steel sheets;

5.Good welding properties.

6.It has good performance-price ratio, durable performance and very competitive price.

As a result, architects, engineers and manufacturers have been using zinc-aluminum coated steel sheets in a wide range of industrial buildings, steel structures and civil facilities, such as: garage doors, gutters and roofs.

Coated sheets, also called organic coated sheets or pre-painted sheets, are made of metal coil (cold rolled sheets, hot-dip galvanized sheets, aluminum-plated sheets, high-aluminum alloy sheets, stainless steel sheets, etc.) as the substrate, and coated with or laminated with various kinds of organic coatings or plastic films on the surface. As it is in the metallurgical plant to complete the surface coating of the coil, can be directly processed by the user into a product, so also known as pre-coated coil.

Coated sheets have both organic polymers and steel sheets of both the advantages of organic polymers, both good coloring, molding, corrosion resistance, decorative, but also the high strength of the steel plate and easy to process, it can be easily punched, bent, deep-drawn, welded and other processing. This makes the products made of organic coated steel sheets have excellent practicality, decorative, processing, durability.

- PPGI (Pre-Painted Galvanized Iron): This refers to galvanized iron steel that has been coated with a layer of zinc and then pre-painted. The zinc layer provides corrosion resistance, while the paint layer enhances aesthetics and additional protection.

- PPGL (Pre-Painted Galvalume): This involves galvanized iron steel coated with an alloy of zinc and aluminum (Galvalume). The Galvalume coating offers superior corrosion resistance compared to traditional galvanized coatings. The pre-painting process is similar to PPGI, adding aesthetic and protective benefits.

PPGI (Pre-Painted Galvanized Iron) material consists of galvanized steel that is coated with zinc to protect against rust and then painted for added durability and aesthetics. The typical layers include:

- Base Steel: Galvanized iron.

- Zinc Coating: Provides primary corrosion resistance.

- Primer Coating: Enhances adhesion between the zinc layer and the top coat.

- Top Coat: Decorative and protective paint layer.

PPGL roofing involves using pre-painted Galvalume sheets for roofing purposes. The advantages include:

- Enhanced Corrosion Resistance: Due to the aluminum-zinc alloy coating.

- Durability: Resistant to harsh weather conditions.

- Aesthetics: Available in various colors and finishes.

- Heat Reflectivity: The aluminum content reflects more heat, keeping buildings cooler.

PPGL coils are used in various applications due to their durability and resistance to corrosion:

- Roofing and Cladding: Commonly used in construction for roofing, wall panels, and facades.

- Automotive: Used in manufacturing vehicle body panels.

- Appliances: Used in making home appliances like refrigerators and washing machines.

- Furniture: Employed in making durable outdoor and indoor furniture.

PPGI coils come in various sizes, typically specified by width, thickness, and weight:

- Width: Commonly ranges from 600 mm to 1250 mm.

- Thickness: Typically ranges from 0.12 mm to 1.5 mm.

- Coil Weight: Usually ranges from 3 to 8 tons per coil.

Coil coating involves applying a coating material to the steel coil before fabrication. Types include:

- Polyester (PE): Standard for general applications.

- High-Durability Polyester (HDP): Improved UV resistance and durability.

- Polyvinylidene Fluoride (PVDF): Excellent weather resistance, used in harsh environments.

- Silicon-Modified Polyester (SMP): Better hardness and weather resistance than standard PE.

- Epoxy: Used for primers and back coatings, offering good adhesion and corrosion resistance.

PPGI sheets vary in thickness based on application requirements:

- Typical Thickness Range: 0.12 mm to 1.2 mm.

- The thickness can be tailored to specific needs, such as thinner sheets for lightweight applications or thicker sheets for enhanced durability.

Galvalume (a coating of zinc, aluminum, and silicon) is used because:

- Superior Corrosion Resistance: The aluminum component provides better protection against corrosion compared to traditional galvanizing.

- Heat Reflectivity: Reflects more heat, making it energy-efficient for roofing applications.

- Durability: Long-lasting, even in harsh environments.

- Self-Healing: The zinc component provides sacrificial protection, covering scratches and minor damages.

If you found this article good, feel free to share it on your other social media platforms.