Hastelloy C-276

With over 11 years of industry expertise, Huaxiao Alloy specializes in providing premium-quality Hastelloy C-276 alloy for the most demanding industry applications. As a professional supplier, we maintain an ISO 9001-certified inventory, ensuring fast, reliable delivery of hard-to-find metals tailored to your specific needs.

Hastelloy C-276 belongs to nickel-molybdenum-chromium-iron-tungsten nickel-based alloy, which is one of the most corrosion-resistant modern metal materials.

Mainly resistant to wet chlorine, a variety of oxidizing chlorides, chloride solutions, sulfuric acid and oxidizing salts, in low temperature and medium temperature hydrochloric acid have good corrosion resistance.

Hastelloy C-276 Production Forms

| Product | Condition |

|---|---|

| Sheet | hot or cold rolled, bright/solution annealed, pickled or de-scaled |

| Strip | cold rolled, bright/solution annealed, pickled or de-scaled |

| Pipe | longitudinally welded or seamless, solution annealed, pickled or de-scaled |

| Bar | hot rolled or forged, solution annealed, pickled or de-scaled |

| Wire | rolled or drawn, solution annealed, pickled or de-scaled |

| Forging | solution annealed, machined on request |

| Welding filler metal | welding bar, wire electrode, coated bar electrode |

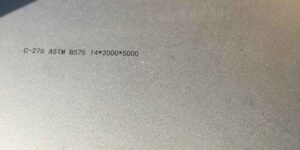

Hastelloy C-276 data sheet

| Specifications | Value |

|---|---|

| DIN Designation | NiMo16Cr15W |

| DIN Material Number | 2.4819 |

| VdTÜV Datasheet | 400 |

| UNS | N10276 |

| DIN | 17744, 17750, 17751, 17752 |

| ASTM | B 574, B 575, B 619, B 622, B 626 |

| ASME | SB 574, SB 575, SB 619, SB 622, SB 626 |

Why Choose Huaxiao Alloy?

- Professional supplier of Hastelloy C-276 and other nickel alloys

- Comprehensive inventory for immediate delivery

- Expertise to help you find the ideal material solution for your applications

Hastelloy C-276 Alloy: Built for the Toughest Challenges

Engineered to excel in harsh chemical environments, Hastelloy C-276 Alloy offers exceptional resistance to pitting, stress-corrosion cracking, and aggressive media such as wet chlorine gas, hypochlorite, and chlorine dioxide. Whether for flue gas desulfurization systems, seawater processing, or other critical chemical processes, this alloy is the reliable choice for durability and performance.

Contact Us Today

Need a trusted partner for Hastelloy C-276 alloy? Contact Huaxiao Alloy now for expert guidance and fast delivery. Let us provide the metal solutions you need to keep your operations running smoothly.

What is Hastelloy C-276 material

Hastelloy C-276 alloy is only a few kinds of corrosion-resistant humid chlorine, hypochlorite and chlorine dioxide solution, one of the materials, the high concentration of chlorinated salt solutions such as ferric chloride and copper chloride have significant corrosion resistance.

Therefore, since nearly three decades, in harsh corrosive environments, such as chemical, petrochemical, flue gas desulfurization, pulp and paper, environmental protection and other industrial fields have a fairly wide range of applications.

In the oxidizing and reducing two atmosphere state, has excellent corrosion resistance to most corrosive media. Excellent resistance to pitting, crevice corrosion and stress corrosion. Higher Mo, Cr content makes the alloy resistant to chloride ion corrosion, W element further improves the corrosion resistance.

Chemical composition of Hastelloy C-276(%)

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15.0-17.0 |

| Chromium (Cr) | 14.5-16.5 |

| Iron (Fe) | 4.0-7.0 |

| Tungsten (W) | 3.0-4.5 |

| Cobalt (Co) | 2.5 max |

| Manganese (Mn) | 1.0 max |

| Vanadium (V) | 0.35 max |

| Silicon (Si) | 0.08 max |

| Carbon (C) | 0.01 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

| Boron (B) | 0.01 max |

Hastelloy C-276 supplier in China——Huaxiao-alloy

Physical properties of Hastelloy C-276

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ (0.321 lb/in³) |

| Melting Range | 1325-1370 °C (2417-2500 °F) |

| Specific Heat Capacity | 427 J/kg·°C (0.102 Btu/lb·°F) at 24°C (75°F) |

| Thermal Conductivity | 10.2 W/m·K (70.9 Btu·in/ft²·h·°F) at 24°C (75°F) |

| Electrical Resistivity | 1.26 µΩ·m (497 µΩ·in) at 24°C (75°F) |

| Modulus of Elasticity | 205 GPa (29700 ksi) |

| Poisson’s Ratio | 0.32 |

| Hardness | Rockwell C (HRC) 32 |

| Coefficient of Thermal Expansion | 11.2 µm/m·°C (6.2 µin/in·°F) from 24-1000°C (75-1832°F) |

Mechanical properties of Hastelloy C-276

| Property | Value |

|---|---|

| Tensile Strength | 790 MPa (115 ksi) |

| Yield Strength (0.2% Offset) | 355 MPa (51.5 ksi) |

| Elongation | 40% |

| Hardness | Rockwell C (HRC) 32 |

| Modulus of Elasticity | 205 GPa (29700 ksi) |

Hastelloy C-276 supplier in China——Huaxiao-alloy

Applications of Hastelloy C-276

Chemical Processing:

- Reaction Vessels: Used in manufacturing chemicals and pharmaceuticals where resistance to strong acids and chlorides is essential.

- Heat Exchangers: Employed in systems requiring heat transfer with corrosive fluids.

- Piping Systems: Ideal for transporting highly corrosive chemicals and gases.

Pollution Control:

- Flue Gas Desulfurization (FGD): Components such as scrubbers, ducting, and stack liners are made from Hastelloy C-276 due to its resistance to sulfur compounds.

- Waste Treatment: Used in incinerators and other waste treatment facilities where exposure to harsh chemicals occurs.

Oil and Gas:

- Downhole Tubing and Safety Valve Equipment: Suitable for use in sour gas environments due to its resistance to sulfide stress cracking.

- Offshore Platforms: Utilized in the construction of components exposed to seawater and harsh marine environments.

Power Generation:

- Nuclear Reactors: Components like control rod drive mechanisms and steam generator tubing are made from Hastelloy C-276 for its resistance to radiation and corrosion.

- Geothermal Energy: Used in heat exchangers and piping systems handling hot, corrosive fluids.

Pharmaceuticals and Biotechnology:

- Sterilization Equipment: Essential in environments requiring sterilization with aggressive chemicals.

- Production Vessels: Used for equipment that must maintain purity and resist chemical attack.

Pulp and Paper Industry:

- Digesters and Bleaching Towers: Resistant to the aggressive chemicals used in paper manufacturing processes.

- Chemical Recovery Units: Ensures long service life in highly corrosive conditions.

Aerospace and Defense:

- Jet Engine Components: Withstands high temperatures and corrosive environments.

- Missile Components: Used in systems requiring high strength and resistance to oxidation.

Hastelloy C-276’s combination of high strength, resistance to corrosion, and ability to withstand extreme temperatures makes it a versatile and valuable material across these and other demanding applications.

FAQs about Hastelloy C-276

Hastelloy C-276 is a nickel-molybdenum-chromium alloy with tungsten, designed to have excellent corrosion resistance in a wide range of severe environments. This superalloy is notable for its resistance to pitting, stress-corrosion cracking, and oxidizing atmospheres up to 1900°F (1038°C). Its robust composition makes it suitable for chemical processing, pollution control, and other industrial applications requiring high performance in harsh conditions.

The ASTM standards for Hastelloy C-276 include:

- ASTM B574: Standard Specification for Nickel Alloy Rod

- ASTM B575: Standard Specification for Nickel Alloy Plate, Sheet, and Strip

- ASTM B619: Standard Specification for Welded Nickel Alloy Pipe

- ASTM B622: Standard Specification for Seamless Nickel Alloy Pipe and Tube

- ASTM B626: Standard Specification for Welded Nickel Alloy Tube

These standards ensure the quality and consistency of Hastelloy C-276 products used in various applications.

Chemical Composition:

- Hastelloy C-22: Contains higher amounts of chromium (20-22.5%) and slightly lower molybdenum (12.5-14.5%) compared to C-276. It also includes iron (2-6%) and tungsten (2.5-3.5%).

- Hastelloy C-276: Contains 15-17% molybdenum, 14.5-16.5% chromium, 4-7% iron, and 3-4.5% tungsten.

Corrosion Resistance:

- Hastelloy C-22: Generally offers better overall corrosion resistance in oxidizing environments compared to C-276.

- Hastelloy C-276: Provides excellent resistance in reducing environments and is known for its outstanding resistance to localized corrosion such as pitting and stress-corrosion cracking.

Applications:

- Hastelloy C-22: Preferred in applications involving both reducing and oxidizing conditions, such as waste treatment and chemical processing.

- Hastelloy C-276: Often used in chemical processing, pollution control, and marine environments, where high resistance to chlorides and other aggressive agents is needed.

N10276 is the UNS (Unified Numbering System) designation for Hastelloy C-276. It refers to the same nickel-molybdenum-chromium alloy known for its excellent corrosion resistance and high performance in harsh environments. This material is widely used in chemical processing, pollution control, and oil and gas industries.

Chemical Composition:

- Hastelloy C-276: Contains higher amounts of molybdenum (15-17%) and tungsten (3-4.5%) compared to Alloy 625.

- Alloy 625 (Inconel 625): Contains lower molybdenum (8-10%) and includes niobium (3.15-4.15%) which is not present in C-276.

Corrosion Resistance:

- Hastelloy C-276: Provides superior resistance to a wide range of corrosive environments, particularly in reducing conditions and environments with chlorides.

- Alloy 625: Known for excellent oxidation and scaling resistance at high temperatures and good corrosion resistance in moderate conditions.

Applications:

- Hastelloy C-276: Used in chemical processing, pollution control, and marine applications.

- Alloy 625: Often used in aerospace, marine, and chemical processing industries, especially where high strength and good weldability are required.

Hastelloy C-276 is chemically compatible with a broad range of corrosive agents. It shows excellent resistance to:

- Strong oxidizers: Such as ferric and cupric chlorides.

- Chlorides: Including brine and seawater, making it suitable for marine environments.

- Acids: Such as sulfuric, hydrochloric, and phosphoric acids.

- Organic acids: Including acetic and formic acids.

- Mixed acid environments: Common in industrial processes.

- Stress-corrosion cracking: Resistant in both reducing and oxidizing conditions.

Conclusion

In conclusion, Hastelloy C-276 is an exemplary alloy known for its exceptional resistance to corrosion, high strength, and stability under extreme environmental conditions. These properties make it ideally suited for demanding industrial applications such as chemical processing, pollution control, oil and gas, power generation, and marine environments.

At the same time, specialized suppliers like Huaxiao-Alloy are dedicated to offering this robust Hastelloy C-276 alloy, ensuring that industries receive materials of the highest quality tailored to withstand severe corrosive environments. Whether it’s for chemical processing equipment, pollution control systems, or high-stress marine applications, Hastelloy C-276 stands as a pivotal solution for advanced material requirements in critical industries.

How to choose a Hastelloy C-276 supplier?

1. Reputation and Experience

- Industry Experience: Look for suppliers with extensive experience in producing and supplying Hastelloy C-276. Long-standing companies typically have a proven track record of reliability and quality.

- Reputation: Research the supplier’s reputation in the market. Check customer reviews, testimonials, and industry references to gauge their credibility.

2. Quality Assurance

- Certifications: Ensure the supplier has relevant certifications such as ISO 9001 for quality management systems. Certifications indicate adherence to high standards.

- Testing and Inspection: Inquire about the supplier’s testing and inspection processes. They should perform rigorous testing to verify the material’s properties and compliance with specifications.

3. Product Range and Availability

- Inventory: A good supplier should have a wide range of Hastelloy C-276 products in various forms (sheets, plates, pipes, bars, etc.) and sizes to meet your needs.

- Lead Times: Check the supplier’s ability to deliver products within your required timeframe. Reliable suppliers maintain adequate stock levels and efficient logistics.

4. Technical Support and Expertise

- Technical Support: Choose a supplier that offers technical support and guidance. They should be able to assist with material selection, application advice, and troubleshooting.

- Expertise: The supplier should have knowledgeable staff who understand the properties and applications of Hastelloy C-276.

5. Compliance and Standards

- Standards Compliance: Ensure the supplier’s products comply with international standards such as ASTM, ASME, DIN, and others relevant to your industry.

- Traceability: The supplier should provide full traceability of their products, including documentation of the material’s origin, production, and testing.

6. Customer Service

- Responsiveness: Evaluate the supplier’s responsiveness to inquiries and their ability to provide prompt and clear communication.

- After-Sales Support: Good suppliers offer robust after-sales support, including handling any issues that arise post-delivery.

7. Price and Value

- Competitive Pricing: Compare prices from different suppliers, but be wary of prices that seem too good to be true. Extremely low prices may indicate compromised quality.

- Value for Money: Consider the overall value, including quality, service, and support, rather than just the lowest price.

8. Sustainability and Ethical Practices

- Sustainable Practices: Consider suppliers who adopt sustainable and environmentally friendly practices in their operations.

- Ethical Standards: Ensure the supplier adheres to ethical business practices, including fair labor practices and corporate social responsibility.

Conclusion

Choosing the right Hastelloy C-276 supplier involves evaluating their reputation, quality assurance processes, product range, technical support, standards compliance, customer service, pricing, and ethical practices. By thoroughly assessing these factors, you can select a supplier who will provide high-quality materials and reliable service, ensuring the success of your projects.