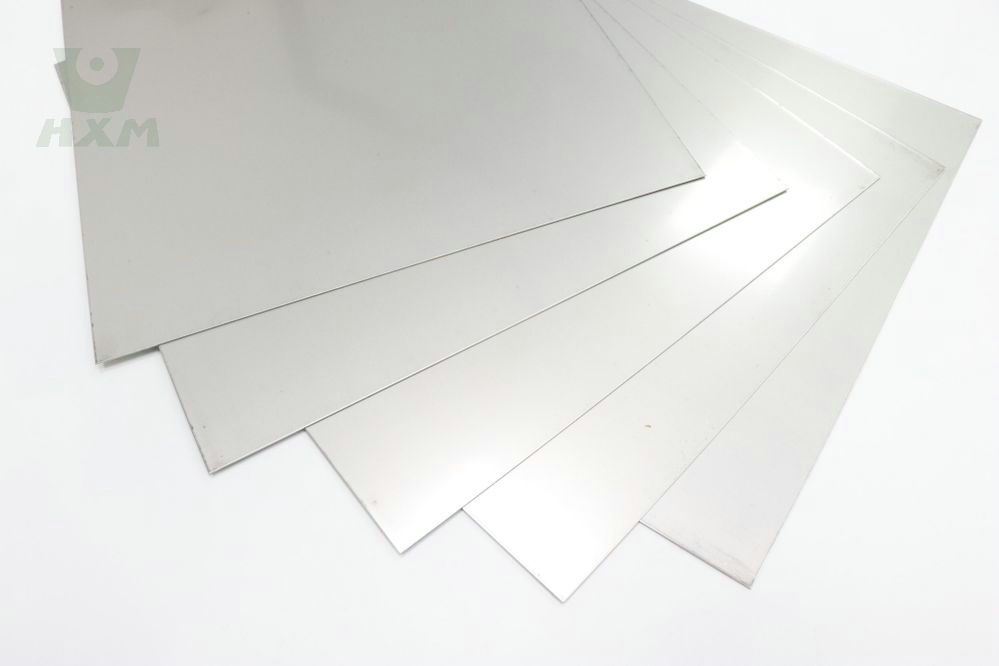

Ti-Ni Shape Memory Alloy

Ti-Ni Shape Memory Alloy, abbreviated as TiNi SMA, is a special alloy with shape memory function. It consists of titanium and nickel elements, and through precise control of its composition and heat treatment process, it has a shape memory effect and superelasticity.

This alloy is capable of undergoing reversible phase transformation within a certain temperature range, thus restoring its original shape.TiNi SMA has a wide range of applications in medical, aerospace, automotive, and electronics fields, such as in the manufacture of intelligent drives, sensors, and actuators.

Due to its unique properties and broad application prospects, TiNi SMA has become a research hotspot in the field of materials science and engineering.

grades of Ti-Ni Shape Memory Alloy

Advantages of Ti-Ni Shape Memory Alloy

The unique advantages of Ti-Ni Shape Memory Alloy (TiNi SMA) are mainly in the following aspects:

1.Shape Memory Effect:

TiNi SMA has an excellent shape memory effect and is able to recover its original shape within a certain temperature range. This property makes it an ideal material for manufacturing smart drivers, sensors and actuators.

2.Superelasticity:

TiNi SMA has excellent superelasticity and is able to recover quickly after being subjected to large deformations. This property makes it useful for a wide range of applications where complex stress changes are required, such as aerospace and automotive manufacturing.

3.Corrosion resistance:

The titanium element in TiNi SMA’s composition provides excellent corrosion resistance, making it resistant to corrosion in a variety of harsh environments. This gives it a wide range of applications in fields such as marine engineering and chemical engineering.

4.Biocompatibility:

Since TiNi SMA is non-toxic to living beings and has good biocompatibility, it has a wide range of applications in the medical field, such as in the manufacture of human implants and medical devices.

5.Easy to process and fabricate:

TiNi SMA has good processing and welding properties, and can be easily cut, bent, drilled and other processing operations. At the same time, its heat treatment process is relatively simple, reducing production costs.

In summary, the unique advantages of TiNi SMA make it stand out among many special alloys. Its shape memory effect, super elasticity, corrosion resistance, biocompatibility and ease of processing and manufacturing make TiNi SMA widely used in medical, aerospace, automotive, chemical and other fields, and become an indispensable and important material in modern industry.

Applications of Ti-Ni Shape Memory Alloy

Titanium-Nickel (Ti-Ni) Shape Memory Alloy (SMA) is known for its unique properties, including shape memory effect, superelasticity, and high biocompatibility. These characteristics make it suitable for a wide range of applications across various industries.

1. Medical Devices

- Stents: Ti-Ni SMA is used in cardiovascular stents, which can be compressed for insertion into blood vessels and then expand to hold the vessel open.

- Orthopedic Implants: The alloy is used in bone plates, screws, and other implants that require the ability to return to a pre-determined shape after being deformed.

- Dental Applications: Ti-Ni wires are commonly used in orthodontics for braces, leveraging the alloy’s ability to exert continuous pressure on teeth to move them into the correct position.

2. Aerospace and Defense

- Actuators: Ti-Ni SMAs are employed in actuators for controlling various aerospace components, such as adaptive wing structures and micro-positioning devices, due to their ability to generate significant force when undergoing phase transformation.

- Aerospace Components: They are used in vibration dampers and other components that require adaptive responses to changing environmental conditions.

3. Robotics

- Artificial Muscles: Ti-Ni SMAs are used to create artificial muscles in robotics, where their ability to contract and expand like biological muscles provides smooth and efficient movement.

- Micro-Actuators: In small-scale robotic systems, Ti-Ni SMA actuators are utilized for precise movements and control.

4. Consumer Electronics

- Flexible Eyeglass Frames: The superelasticity of Ti-Ni SMA is used in eyeglass frames, allowing them to return to their original shape after being bent.

- Mobile Phone Components: SMA springs and actuators are used in mobile phones for various functions, including camera lens stabilization and haptic feedback systems.

5. Automotive Industry

- Temperature Control Systems: Ti-Ni SMAs are used in automotive temperature control systems, such as air conditioning vents and engine cooling systems, to regulate air or fluid flow.

- Impact-Absorbing Components: The alloy’s superelastic properties are employed in crash-resistant components that absorb energy during impact.

6. Industrial Applications

- Couplings and Fasteners: Ti-Ni SMA is used in couplings and fasteners that require a secure fit at one temperature and easy disassembly at another.

- Valve and Pipe Control: The alloy is used in valves and pipe systems that require automatic adjustment based on temperature changes.

Summary

Ti-Ni Shape Memory Alloy is a versatile material with unique properties that make it valuable across multiple industries. From medical devices and aerospace components to consumer electronics and automotive applications, Ti-Ni SMA plays a critical role in modern technology due to its shape memory effect, superelasticity, and biocompatibility.

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Dutch

Dutch English

English French

French German

German Italian

Italian Japanese

Japanese Korean

Korean Malayalam

Malayalam Mongolian

Mongolian Norwegian

Norwegian Portuguese

Portuguese Russian

Russian Serbian

Serbian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish