High-temperature Alloy Strip

Product grades: GH2132, GH4169, GH3039, GH4145, GH3128

Implementation standards: GB/T 14992, ASTM A336, ASTM B637, ASTM B168, and other relevant standards

Certification: ISO9001:2015

Features: Exceptional high-temperature strength and creep rupture properties. These alloys maintain stability and durability at temperatures exceeding 700°C, making them ideal for use in extreme environments.

Product usage: Aerospace, chemical processing, power generation, gas turbines, and marine industries.

MOQ: 500KG

Payment method: T/T, LC

Price: To negotiateb

High-temperature Alloy Strip dimensions

| Parameter | Details |

|---|---|

| Thickness | 0.2 mm – 3.0 mm |

| Width | 100 mm – 1000 mm (or as requested) |

| Length | Coil or customized length |

| Tolerance | Thickness: ±0.02 mm, Width: ±0.1 mm |

| Surface Finish | Mirror, polished, or as specified |

| Edge Condition | Slit edge, mill edge |

Different grades of High-temperature Alloy

High-temperature Alloy Strip is a specialized material designed for use in extreme environments, where high heat resistance, excellent strength, and stability are required. These strips maintain their mechanical properties at elevated temperatures, making them ideal for applications in the aerospace, power generation, and chemical processing industries. Common high-temperature alloys include Inconel, Hastelloy, and GH series alloys, known for their ability to resist oxidation and creep at temperatures exceeding 700°C.

Mechanical Properties of High-temperature Alloy

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Creep Rupture Strength (MPa at 700°C) | Operating Temp (°C) |

|---|---|---|---|---|---|---|

| GH2132 | 930 – 1080 | 600 – 800 | 20 – 30 | 220 – 280 | 140 MPa | Up to 700°C |

| GH4169 | 1000 – 1400 | 600 – 1050 | 15 – 25 | 220 – 300 | 180 MPa | Up to 650°C |

| GH3039 | 980 – 1200 | 600 – 800 | 25 – 40 | 200 – 240 | 150 MPa | Up to 900°C |

| GH4145 | 850 – 1100 | 500 – 750 | 20 – 30 | 180 – 250 | 120 MPa | Up to 700°C |

| GH3128 | 920 – 1150 | 550 – 800 | 20 – 35 | 210 – 270 | 130 MPa | Up to 800°C |

Advantages of each High-temperature Alloy Strip

GH2132:

- GH2132 offers excellent oxidation and corrosion resistance at high temperatures, making it ideal for environments up to 700°C. Its high tensile and yield strength provide great stability under stress. Additionally, GH2132 has good fatigue resistance, which is beneficial for demanding applications such as gas turbines and aerospace components. Its formability and weldability further enhance its versatility in manufacturing.

GH4169:

- GH4169 stands out due to its superior creep resistance and high tensile strength, especially in high-stress conditions. It exhibits excellent oxidation and corrosion resistance up to 650°C. This alloy also shows good fatigue and impact resistance, making it well-suited for aerospace, marine, and nuclear applications, where both durability and long-term performance are critical.

GH3039:

- GH3039 is known for its high mechanical strength and exceptional resistance to oxidation at temperatures as high as 900°C. It excels in environments subject to thermal fatigue and creep. This alloy is commonly used in gas turbines, jet engines, and other high-temperature machinery, thanks to its ability to maintain performance in extreme heat.

GH4145:

- GH4145 offers outstanding resistance to heat and oxidation, maintaining its mechanical properties at high temperatures. This makes it a great choice for nuclear reactors, power generation equipment, and other high-heat applications. It provides good mechanical stability under stress, ensuring reliability in challenging environments.

GH3128:

- GH3128 provides excellent temperature stability and oxidation resistance up to 800°C. Its thermal fatigue resistance, combined with high strength, makes it a suitable material for chemical processing and power generation applications. GH3128 performs well in environments where both heat and chemical resistance are required.

These descriptions highlight the specific advantages of each alloy, focusing on their performance in high-temperature and challenging industrial environments.

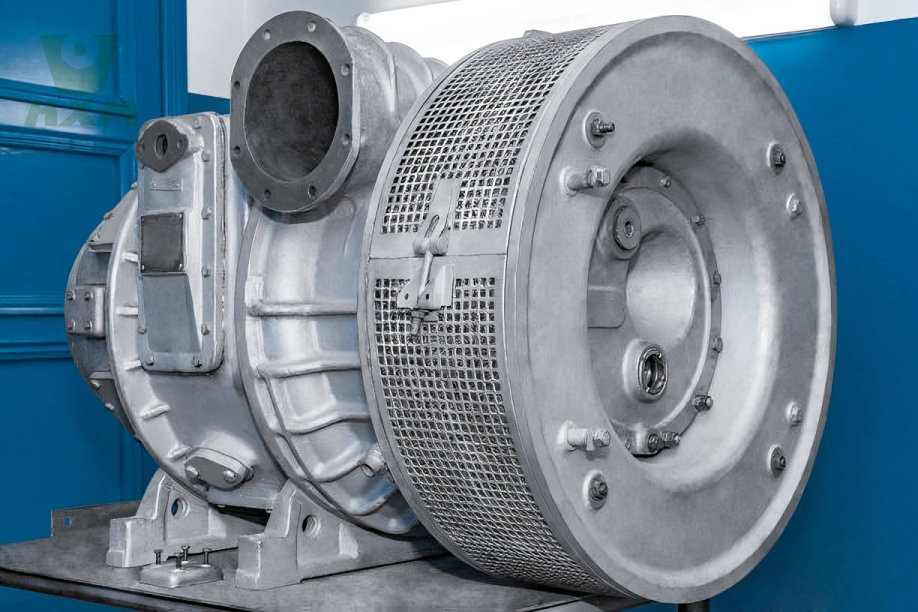

Applications of High-temperature Alloy Strip

High-temperature alloy strips are widely used across various industries due to their excellent resistance to heat, oxidation, and mechanical stress. Here are the key applications of high-temperature alloy strips:

Aerospace Industry:

- Used in components like turbine blades, exhaust systems, combustion chambers, and afterburners where resistance to extreme heat and high stress is essential. These alloys ensure long-term durability and performance in both aircraft and spacecraft systems.

Power Generation:

- High-temperature alloys are critical in gas turbines, steam turbines, and heat exchangers in power plants. Their ability to withstand high temperatures and resist creep ensures the efficiency and reliability of power generation equipment.

Gas Turbines and Jet Engines:

- These strips are vital for constructing components that endure continuous exposure to high-temperature gases, such as turbine discs and nozzles. Their strength and resistance to thermal fatigue ensure the safe operation of turbines and engines in both aviation and industrial power systems.

Nuclear Reactors:

- High-temperature alloys are used in reactors due to their ability to maintain mechanical properties under extreme heat and radiation. They are found in core components, pressure vessels, and heat exchangers where both corrosion resistance and high strength are required.

Chemical Processing:

- In chemical plants, these alloys are used in furnaces, reactors, and heat-treating equipment, where both high temperature and corrosion resistance are critical. They perform well in harsh chemical environments and high heat, ensuring the longevity and safety of the equipment.

Marine Engineering:

- High-temperature alloy strips are used in marine environments, especially in engines, exhaust systems, and other components exposed to high heat and corrosive conditions. Their durability and resistance to saltwater corrosion make them ideal for naval applications.

Automotive Industry:

- These alloys are used in the construction of components like exhaust manifolds, turbochargers, and other parts that experience high thermal loads. Their ability to withstand heat and thermal fatigue improves vehicle performance and lifespan.

Oil and Gas Industry:

- In high-pressure, high-temperature drilling environments, these alloys are essential for components such as downhole tubing and tools. Their resistance to extreme temperatures and corrosive conditions helps ensure the reliability and safety of oil extraction processes.

Heat Treatment Equipment:

- High-temperature alloy strips are used in the manufacturing of heat treatment equipment like furnaces and kilns, where continuous exposure to high temperatures is necessary. Their resistance to thermal expansion and oxidation ensures the equipment remains functional over extended periods.

These applications demonstrate the versatility of high-temperature alloy strips in industries that demand exceptional performance under extreme conditions.

FAQs

High-temperature metal alloys are designed to withstand extreme heat while maintaining their mechanical properties, such as strength, oxidation resistance, and creep resistance. Some of the best metal alloys for high temperatures include:

- Inconel (Nickel-based alloys): Exceptional resistance to heat and corrosion, making it suitable for temperatures up to 1000°C or more.

- Hastelloy: Known for its high heat and corrosion resistance, commonly used in chemical processing and power generation.

- Stainless Steel (300 series): Grades like 310 and 316 offer good high-temperature resistance, used in furnace parts and heat exchangers.

Aluminum alloys generally have lower melting points compared to steel and nickel-based alloys, but there are a few that perform well at moderately high temperatures:

- 6061 Aluminum Alloy: Can withstand temperatures up to 250°C, commonly used in automotive and aerospace applications.

- 7075 Aluminum Alloy: Offers good mechanical properties and can handle temperatures up to 300°C, often used in aircraft structural components.

- 2618 Aluminum Alloy: Used in high-performance engine components, it can withstand higher temperatures (up to 300°C) compared to most other aluminum alloys.

Steel alloys that are specifically designed for high-temperature applications include:

- 310 Stainless Steel: Can withstand temperatures up to 1100°C, known for excellent oxidation resistance.

- 316 Stainless Steel: Provides heat resistance up to 800°C, often used in chemical and marine environments.

- H-Series Tool Steels (H13): Used in hot-working applications such as die-casting and extrusion, they offer great resistance to heat and wear.

Yes, Inconel is a high-temperature alloy. It is a nickel-based superalloy known for its ability to withstand extreme temperatures (up to 1000°C or higher) and maintain strength and corrosion resistance. It is widely used in gas turbines, jet engines, and high-temperature industrial applications.

The best alloy for high-heat applications typically depends on the specific requirements of the environment. However, nickel-based superalloys like Inconel and Hastelloy are often considered the best due to their ability to retain strength and resist oxidation at extremely high temperatures (up to 1000°C or more). These alloys are commonly used in aerospace, power generation, and chemical processing industries.

For temperatures as high as 1500°C, only a few metal alloys can maintain structural integrity:

- Tungsten: Melting point of 3422°C, often used in extremely high-temperature environments.

- Molybdenum: Can withstand temperatures up to 2620°C, used in furnace components and high-temperature processing.

- Tantalum: Can endure temperatures up to 2996°C, often used in heat exchangers and chemical equipment.

For practical industrial applications involving high temperatures around 1500°C, ceramic materials are also commonly used as metals typically start to degrade at such extreme conditions.

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Dutch

Dutch English

English French

French German

German Italian

Italian Japanese

Japanese Korean

Korean Malayalam

Malayalam Mongolian

Mongolian Norwegian

Norwegian Portuguese

Portuguese Russian

Russian Serbian

Serbian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish