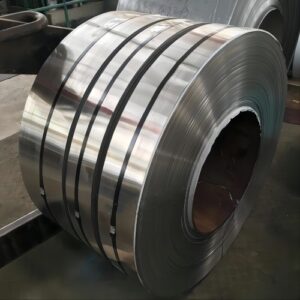

Inconel 690 Sheet / Plate / Coil

Inconel 690 is a nickel-chromium-iron alloy renowned for its exceptional resistance to high-temperature oxidation, carburization, and sulfur-based corrosion. As a leading Inconel 690 Sheet/Plate/Coil manufacturer, Huaxiao-Alloy supplies this alloy under the following designations:

- UNS N06690

- EN 2.4642

- W. Nr. 2.4642

Huaxiao-Alloy’s Inconel 690 products adhere to stringent international standards, ensuring reliability for critical industrial applications:

- ASTM B168 (Sheet/Plate)

- ASTM B906 (Coil)

- ASME SB168

- EN 10095

- DIN 17752

Our Inconel 690 Plate supplier team rigorously tests materials to meet certifications such as ISO 9001, PED, and NACE MR0175.

Available Product Specifications

| Product Form | Thickness (mm) | Width (mm) | Length (mm) | Surface Finish |

|---|---|---|---|---|

| Sheet | 0.5–50 | 1000–3000 | 2000–6000 | Cold-rolled, Annealed |

| Plate | 5–150 | 1500–4000 | 3000–12000 | Hot-rolled, Pickled |

| Coil | 0.5–6 | 300–1500 | Custom | Annealed, Polished |

Custom dimensions and tolerances are available upon request from this Inconel 690 Coil manufacturer.

Mechanical Properties

Inconel 690 delivers superior performance under extreme conditions:

- Tensile Strength: 550–760 MPa

- Yield Strength (0.2% Offset): 240–310 MPa

- Elongation: 30–40%

- Hardness: 150–200 HB

- Density: 8.19 g/cm³

These properties make Huaxiao-Alloy’s Inconel 690 Sheet ideal for nuclear, aerospace, and chemical processing industries.

Chemical Composition

| Element | Ni | Cr | Fe | C | Mn | Si | Cu | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|

| **% Content** | ≥58 | 28–31 | 7–11 | ≤0.05 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

The high chromium-nickel ratio ensures resistance to stress corrosion cracking (SCC), a hallmark of Huaxiao-Alloy’s Inconel 690 Plate.

The high chromium-nickel ratio ensures resistance to stress corrosion cracking (SCC), a hallmark of Huaxiao-Alloy’s Inconel 690 Plate.

Cross-National Designations

| Country | Standard | Equivalent Grade |

|---|---|---|

| USA | ASTM/ASME | UNS N06690 |

| Europe | EN | 2.4642 |

| Japan | JIS | NCF 690 |

| Germany | DIN | W. Nr. 2.4642 |

| China | GB | NS315 |

As a global Inconel 690 Sheet supplier, we ensure compliance with regional certifications for seamless integration into your supply chain.

Key Characteristics

- High-Temperature Stability: Retains structural integrity up to 1100°C (2012°F).

- Corrosion Resistance: Excellent resistance to oxidizing, sulfidizing, and chlorinated environments.

- Weldability: Compatible with TIG, MIG, and plasma arc welding methods.

- Thermal Fatigue Resistance: Ideal for cyclic heating/cooling applications.

- Low Thermal Expansion: Minimizes distortion under thermal stress.

These attributes make Huaxiao-Alloy’s Inconel 690 Coil a preferred choice for demanding sectors like power generation and petrochemical refining.

Applications

- Nuclear Power: Steam generator tubes, reactor core components.

- Chemical Processing: Heat exchangers, furnace retorts, and catalytic reforming units.

- Aerospace: Combustion liners, exhaust systems.

- Oil & Gas: Flue gas desulfurization systems, flare stacks.

- Renewable Energy: Solar thermal and geothermal energy systems.

Trust Huaxiao-Alloy, a premier Inconel 690 Plate manufacturer, to deliver materials for mission-critical projects.

Why Choose Huaxiao-Alloy?

- Technical Mastery: 20+ years of expertise in advanced alloy production.

- Custom Fabrication: Laser cutting, precision machining, and forming services.

- Competitive Pricing: Cost-effective solutions without compromising quality.

- Global Reach: Efficient logistics network serving 50+ countries.

- Sustainability: Eco-friendly manufacturing processes aligned with ISO 14001.

Our Inconel 690 Sheet supplier team provides end-to-end support, including material selection guidance and post-sales technical assistance.

Get Quote Now

FAQs

Inconel 690 performs reliably up to 1100°C (2012°F) in oxidizing environments.

Yes, we supply third-party test reports (e.g., intergranular corrosion, pitting resistance) upon request.

Absolutely. As a flexible Inconel 690 Coil manufacturer, we tailor products to your specifications.

Inconel 690 offers superior chromium content (29% vs. 15%), enhancing oxidation and SCC resistance.

We use wooden crates, waterproof wrapping, and palletization to ensure damage-free transit.