316L Stainless Steel

As a leading 316L stainless steel manufacturer and supplier, Huaxiao-Alloy combines decades of metallurgical expertise with advanced production technologies to deliver high-performance stainless steel solutions for the most demanding environments. This guide provides an in-depth analysis of 316L stainless steel, including its applications, supply forms, chemical composition, mechanical and physical properties, and answers to key industry FAQs.

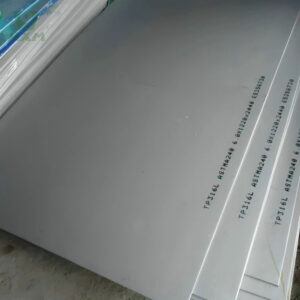

Our Supply Forms & Dimensions of 316L stainless steel

As a premier 316L stainless steel manufacturer, Huaxiao-Alloy offers the alloy in versatile forms tailored to industrial needs:

| Form | Dimensions | Standards |

|---|---|---|

| Sheets/Plates | Thickness: 0.5mm–100mm; Width: 600–2500mm | ASTM A240, EN 1.4404 |

| Coils | Thickness: 0.3–6mm; Width: 10–1500mm | JIS SUS316L, GB/T 4237 |

| Bars/Rods | Diameter: 5mm–500mm; Length: 1–12m | ASTM A276, ASTM A479 |

| Tubes/Pipes | OD: 6–1200mm; Wall Thickness: 0.5–50mm | ASTM A312, ASTM A269 |

| Wire | Diameter: 0.1–10mm | ASTM A580, DIN 17440 |

Custom tolerances (±5%), finishes (e.g., 2B, BA, No.8 mirror), and packaging solutions available.

What is 316L Stainless Steel?

316L stainless steel (UNS S31603) is a low-carbon variant of the standard 316 alloy, designed to minimize carbide precipitation during welding and high-temperature exposure. With a maximum carbon content of 0.03%, it offers superior intergranular corrosion resistance compared to 316 stainless steel. Huaxiao-Alloy, as a premier 316L stainless steel supplier, ensures compliance with global standards such as ASTM A240, EN 1.4404, and JIS SUS316L.

Applications of 316L Stainless Steel

Key Industrial & Commercial Uses

- Chemical & Petrochemical: Tanks, heat exchangers, and piping systems exposed to sulfuric acid, chlorides, and bromides.

- Marine Engineering: Offshore platforms, ship components, and desalination plants due to superior chloride resistance.

- Pharmaceuticals: Bioreactors, sterile tubing, and clean-in-place (CIP) systems.

- Medical Implants: Surgical instruments, orthopedic devices, and implants (ASTM F138/F139 compliant).

- Oil & Gas: Subsea equipment, pipelines, and flare stacks in corrosive environments.

- Food Processing: Equipment for acidic food products (e.g., vinegar, citrus juices).

Why Partner with Huaxiao-Alloy?

- Certifications: ISO 9001:2015, ASME, and PED 2014/68/EU compliance.

- Custom Fabrication: Precision cutting, welding, polishing, and CNC machining.

- Global Logistics: Efficient delivery to Europe, North America, and Asia-Pacific.

Chemical Composition of 316L stainless steel

The exceptional corrosion resistance of 316L stainless steel stems from its optimized chemistry:

| Element | Content (%) | Role |

|---|---|---|

| Chromium (Cr) | 16.0–18.0 | Forms a passive oxide layer for corrosion resistance. |

| Nickel (Ni) | 10.0–14.0 | Stabilizes austenitic structure and ductility. |

| Molybdenum (Mo) | 2.0–3.0 | Enhances pitting and crevice corrosion resistance. |

| Carbon (C) | ≤0.03 | Minimizes carbide precipitation during welding. |

| Manganese (Mn) | ≤2.0 | Improves hot workability. |

| Silicon (Si) | ≤1.0 | Deoxidizer during smelting. |

| Phosphorus (P) | ≤0.045 | Reduces brittleness. |

| Sulfur (S) | ≤0.03 | Enhances machinability. |

| Iron (Fe) | Balance | Base metal. |

Complies with ASTM A240, EN 1.4404, and JIS SUS316L specifications.

Mechanical Properties of 316L stainless steel

316L stainless steel balances strength, ductility, and weldability:

| Property | Value |

|---|---|

| Tensile Strength | 485–690 MPa |

| Yield Strength (0.2% offset) | 170 MPa (min) |

| Elongation (50mm gauge) | 40% (min) |

| Hardness (Brinell) | 217 HB (max) |

| Modulus of Elasticity | 193 GPa |

Note: Annealing at 1010–1120°C followed by rapid cooling optimizes corrosion resistance.

Physical Properties of 316L stainless steel

| Property | Value |

|---|---|

| Density | 8,000 kg/m³ |

| Melting Point | 1375–1400°C |

| Thermal Conductivity | 15.0 W/m·K (at 100°C) |

| Electrical Resistivity | 0.74 μΩ·m |

| Magnetic Permeability | <1.02 (Annealed, non-magnetic) |

316L vs 316 Stainless Steel: Key Differences

| Parameter | 316L | 316 |

|---|---|---|

| Carbon Content | ≤0.03% | ≤0.08% |

| Weldability | Superior (no post-weld annealing required) | Requires post-weld annealing for heavy sections |

| Intergranular Corrosion Resistance | Excellent | Moderate |

| Applications | Welded structures, high-temperature environments | General-purpose uses with moderate welding needs |

316L’s low carbon content minimizes carbide precipitation during welding, making it ideal for welded components and high-temperature applications.

Yes, it resists sulfuric acid at moderate concentrations and temperatures. Consult Huaxiao-Alloy’s corrosion resistance charts for specific conditions.

Yes, its molybdenum content provides excellent resistance to chloride-induced pitting corrosion in seawater.

Options include 2B (cold-rolled), BA (bright annealed), No.8 mirror, and electro-polished finishes for hygienic or decorative applications.

Yes, we provide ASTM F138/F139-certified 316L for surgical tools and implants.

Yes, we provide Mill Test Reports (MTRs), ISO 9001, and material traceability documentation.