904L Stainless Steel

As a leading 904L stainless steel manufacturer and supplier, Huaxiao-Alloy leverages decades of metallurgical expertise to deliver high-performance alloys for the most demanding industrial environments. This guide explores the unique properties, applications, and technical specifications of 904L stainless steel, alongside FAQs and a comparison with other alloys.

Our Supply Forms & Dimensions

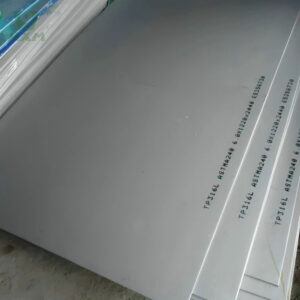

As a leading 904L stainless steel manufacturer, Huaxiao-Alloy supplies the alloy in versatile forms:

| Form | Dimensions | Standards |

|---|---|---|

| Sheets/Plates | Thickness: 0.5–50mm; Width: 600–2500mm | ASTM B625, EN 1.4539 |

| Coils | Thickness: 0.5–6mm; Width: 10–1500mm | EN 10088-3, DIN 17443 |

| Bars/Rods | Diameter: 5–500mm; Length: 1–12m | ASTM B688, ASTM A479 |

| Tubes/Pipes | OD: 10–1200mm; Wall Thickness: 1–50mm | ASTM B677, ASTM A312 |

| Fittings/Flanges | ANSI B16.5, DIN, JIS standards | ASME B16.9, EN 10253 |

Custom sizes (±5% tolerance), finishes (e.g., 2B, electropolished), and certifications available.

What is 904L Stainless Steel?

904L stainless steel (UNS N08904, EN 1.4539) is a super-austenitic stainless steel renowned for its exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. With high nickel (23–28%), chromium (19–23%), and molybdenum (4–5%) content, it excels in aggressive environments like sulfuric acid, seawater, and chloride-rich settings. Huaxiao-Alloy, as a premier 904L stainless steel supplier, ensures compliance with ASTM B625, EN 10088-3, and other global standards.

Applications of 904L Stainless Steel

Critical Industrial Uses

- Chemical Processing: Reactors, heat exchangers, and piping for sulfuric, phosphoric, and acetic acid handling.

- Oil & Gas: Offshore platforms, subsea pipelines, and sour gas equipment.

- Marine Engineering: Desalination plants, seawater cooling systems, and ship components.

- Pharmaceuticals: Bioreactors, CIP systems, and sterile storage tanks.

- Pulp & Paper: Bleaching equipment and chemical recovery systems.

Why Partner with Huaxiao-Alloy?

- Certifications: ISO 9001:2015, NACE MR0175, and PED 2014/68/EU compliance.

- Custom Fabrication: Precision machining, welding, and surface finishing.

- Global Logistics: Timely delivery to Europe, Asia, and the Americas.

Chemical Composition of 904L stainless steel

904L’s corrosion resistance stems from its high alloy content:

| Element | Content (%) | Role |

|---|---|---|

| Chromium (Cr) | 19.0–23.0 | Enhances oxidation resistance. |

| Nickel (Ni) | 23.0–28.0 | Stabilizes austenitic structure. |

| Molybdenum (Mo) | 4.0–5.0 | Resists pitting and crevice corrosion. |

| Copper (Cu) | 1.0–2.0 | Improves resistance to sulfuric acid. |

| Manganese (Mn) | ≤2.0 | Enhances hot workability. |

| Carbon (C) | ≤0.02 | Minimizes carbide precipitation. |

| Silicon (Si) | ≤1.0 | Deoxidizer during smelting. |

| Iron (Fe) | Balance | Base metal. |

Complies with UNS N08904, EN 1.4539, and ASTM B625 specifications.

Mechanical Properties of 904L stainless steel

904L stainless steel offers robust performance under stress:

| Property | Value |

|---|---|

| Tensile Strength | 490–690 MPa |

| Yield Strength (0.2% offset) | 220 MPa (min) |

| Elongation (50mm gauge) | 35% (min) |

| Hardness (Brinell) | 190–220 HB |

| Modulus of Elasticity | 200 GPa |

Note: Solution annealing at 1100–1175°C followed by rapid cooling optimizes properties.

Physical Properties of 904L stainless steel

| Property | Value |

|---|---|

| Density | 8,000 kg/m³ |

| Melting Point | 1300–1390°C |

| Thermal Conductivity | 12.5 W/m·K (at 100°C) |

| Electrical Resistivity | 0.85 μΩ·m |

| Magnetic Permeability | <1.02 (Non-magnetic) |

904L vs 316L Stainless Steel: Key Differences

| Parameter | 904L | 316L |

|---|---|---|

| Nickel Content | 23–28% | 10–14% |

| Molybdenum Content | 4–5% | 2–3% |

| Corrosion Resistance | Superior in sulfuric acid, chlorides, and seawater | Moderate in mild chlorides |

| Cost | 3–5x higher | Lower |

| Applications | Extreme chemical and marine environments | General-purpose corrosion resistance |

Its high nickel, molybdenum, and copper content increase raw material costs, but its longevity in extreme environments justifies the investment.

Yes, it has excellent weldability using matching filler materials (e.g., ER385). Post-weld annealing is not required.

Yes, it resists pitting and crevice corrosion even in high-chloride seawater.

We provide Mill Test Reports (MTRs), ISO 9001, and NACE MR0175 compliance for sour service.

Yes, due to its high work hardening rate, carbide-tipped or high-speed steel tools are recommended.

904L Stainless Steel Data Sheet

Call Us Now!!!

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Dutch

Dutch English

English French

French German

German Italian

Italian Japanese

Japanese Korean

Korean Malayalam

Malayalam Mongolian

Mongolian Norwegian

Norwegian Portuguese

Portuguese Russian

Russian Serbian

Serbian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish