AMS 4575 Monel alloy is a nickel–copper-based material that has garnered significant attention in the metallurgical industry due to its exceptional corrosion resistance and mechanical properties. As a seasoned expert in the field of metal materials from Huaxiao Alloy, I am delighted to delve into the composition, properties, and uses of this remarkable alloy.

AMS 4575 Monel Alloy – Composition, Properties and Uses

1. Composition

The composition of AMS 4575 Monel alloy is a carefully balanced blend of nickel and copper, with small additions of other elements to enhance specific properties. Nickel, the primary constituent, accounts for approximately 63% of the alloy’s composition, conferring excellent corrosion resistance and mechanical strength. Copper, comprising approximately 30%, contributes to the alloy’s ductility and electrical conductivity. Additionally, trace amounts of iron, manganese, sulfur, carbon, and silicon are added to fine-tune the alloy’s properties, such as enhancing its resistance to oxidation and improving its weldability.

2. Properties

AMS 4575 Monel alloy exhibits a remarkable array of properties that make it a standout material in various applications. Firstly, its corrosion resistance is unparalleled, especially in marine and chemical processing environments. The formation of a protective oxide layer on the alloy’s surface effectively shields it from harmful corrosive agents, ensuring long-term durability.

Moreover, the alloy possesses excellent mechanical properties. It exhibits high tensile strength and yield strength, allowing it to withstand significant loads without deformation. Its ductility and toughness enable it to be easily formed and shaped into complex geometries, making it suitable for a wide range of manufacturing processes.

AMS 4575 Monel alloy also demonstrates good weldability and machinability. It can be welded using various techniques, and its machinability allows for precise cutting and shaping, further enhancing its versatility.

3. Uses

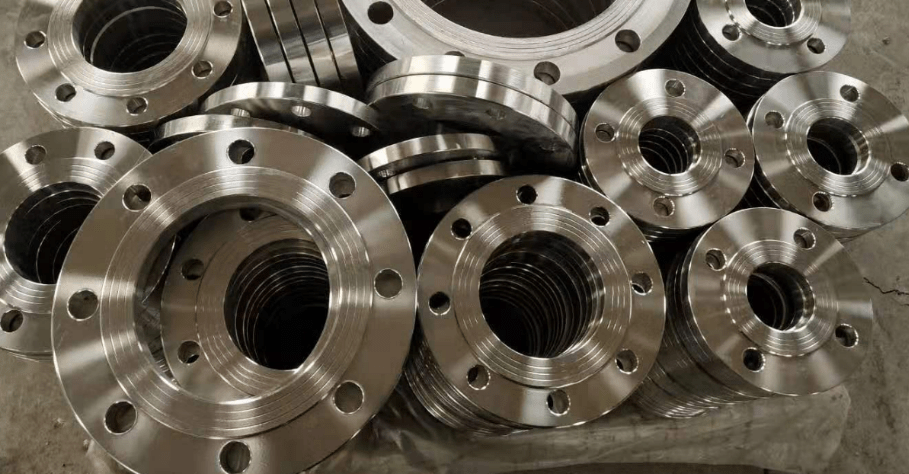

The diverse set of properties exhibited by AMS 4575 Monel alloy has led to its widespread use in numerous industries. One of the primary applications is in the marine industry, where its corrosion resistance makes it a preferred choice for components such as pumps, valves, and fasteners. The alloy’s ability to withstand the harsh conditions of seawater and salt air ensures reliable performance even in the most demanding environments.

In the chemical processing industry, AMS 4575 Monel alloy is used in equipment and piping systems that handle corrosive chemicals. Its resistance to acids and alkalis ensures the safety and integrity of the processing operations, minimizing the risk of leaks and failures.

The alloy also finds its way into the aerospace industry, where its high strength and corrosion resistance are crucial for components that must endure extreme temperatures and pressures. AMS 4575 Monel alloy is often used in aircraft and spacecraft for structural parts and fasteners, contributing to the overall safety and reliability of the vehicles.

Furthermore, the alloy’s electrical conductivity and corrosion resistance make it a suitable choice for electrical and electronic applications. It is commonly used in connectors, switches, and other components that require long-term reliability and stability.

Conclusion

AMS 4575 Monel alloy, with its unique composition and exceptional properties, has established itself as a reliable and dependable material in various industries. Its corrosion resistance, mechanical properties, weldability, and machinability make it a versatile choice for applications that demand durability and performance.

Thank you for reading our article and we hope it can help you to have a better understanding of the AMS 4575 Monel Alloy. If you are looking for Monel Alloy suppliers online now, we would advise you to contact Huaxiao Alloy.

As a leading supplier of Monel Alloy products from Shanghai China, Huaxiao Alloy offers customers high-quality Monel 400 Alloy, Monel 405 Alloy, Monel K500, Inconel 602 Alloy, Hastelloy S Alloy, Inconel Alloy 600, Inconel Alloy 601, Inconel 625 UNS N06625, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), and Hastelloy C-2000 at a very competitive price.