AMS 4675 Monel alloy, a notable material within the realm of nickel–copper alloys, has established a solid reputation for its remarkable corrosion resistance and mechanical properties. Its unique composition and resulting characteristics have made it a preferred choice in a wide range of industrial applications. In this article, we aim to provide a comprehensive, accurate, and authoritative overview of the composition, properties, and uses of AMS 4675 Monel alloy.

AMS 4675 Monel Alloy – Composition, Properties and Uses

Composition

The cornerstone of AMS 4675 Monel alloy’s performance lies in its precise composition. Primarily composed of nickel and copper, this alloy typically contains approximately 67% nickel and 30% copper. The remaining percentage is made up of trace elements, such as iron, manganese, sulfur, carbon, and silicon, each playing a crucial role in enhancing the alloy’s overall performance. The carefully controlled composition ensures consistent mechanical and corrosion resistance properties.

Properties

AMS 4675 Monel alloy boasts an impressive array of properties that set it apart from other metals. Its most noteworthy feature is its exceptional corrosion resistance, which allows it to thrive in even the most aggressive environments. This resilience against corrosion is attributed to the formation of a protective oxide layer on the alloy’s surface, providing a robust barrier against harmful elements.

Moreover, AMS 4675 Monel alloy exhibits excellent mechanical properties. It possesses high tensile strength and yield strength, making it suitable for applications that require robust structural integrity. Its ductility and toughness also contribute to its versatility, enabling it to be easily formed and shaped into complex geometries.

In addition to its corrosion resistance and mechanical properties, AMS 4675 Monel alloy also demonstrates good weldability and machinability. It can be welded using various techniques, and its machinability allows for precise and efficient manufacturing processes.

Uses

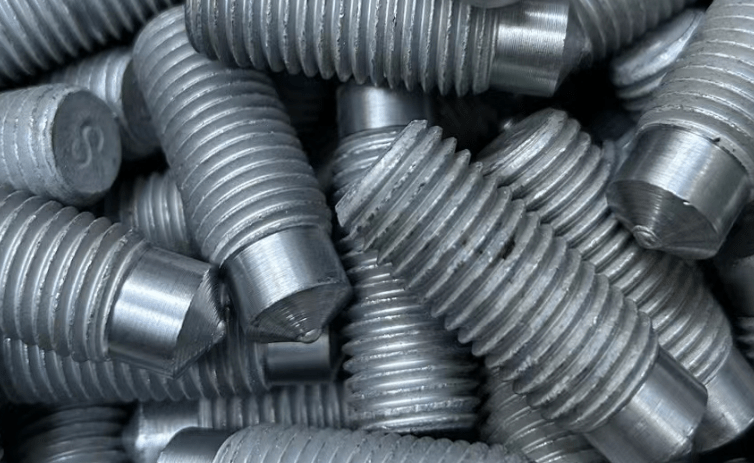

The diverse set of properties exhibited by AMS 4675 Monel alloy has led to its widespread use in numerous industries. One of the primary applications is in the marine industry, where its corrosion resistance is crucial for withstanding the harsh conditions of seawater and salt air. Components such as pumps, valves, and fasteners made from this alloy can maintain their integrity for extended periods, even in the most corrosive environments.

The chemical processing industry also heavily relies on AMS 4675 Monel alloy. Its resistance to various acids and alkalis makes it an ideal material for equipment and piping systems that handle corrosive chemicals. The alloy’s durability ensures the safety and reliability of chemical processing operations.

In the aerospace industry, AMS 4675 Monel alloy is often used in components that require high strength and corrosion resistance. Its ability to maintain its properties even under extreme temperatures and pressures makes it a suitable choice for aircraft and spacecraft applications.

Moreover, the alloy finds its way into the electrical and electronic industries. Its excellent electrical conductivity and corrosion resistance are valuable attributes in connectors, switches, and other electrical components that require long-term reliability.

Conclusion

AMS 4675 Monel alloy, with its unique composition and exceptional properties, has become a trusted material in various industries. Its corrosion resistance, mechanical properties, weldability, and machinability make it a versatile choice for applications that demand durability and performance.

Thank you for reading our article and we hope it can help you to have a better understanding of the AMS 4675 Monel Alloy. If you are looking for Monel Alloy suppliers online, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel Alloy products from Shanghai China, Huaxiao Alloy offers high-quality Monel 400 Alloy, Monel 405 Alloy, Monel K500, Inconel 602 Alloy, Hastelloy S Alloy, Inconel Alloy 600, Inconel Alloy 601, Inconel 625 UNS N06625, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), and Hastelloy C-2000 at a very competitive price.