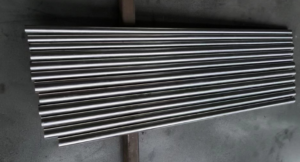

Monel 400 alloy, as a superior-performing alloy material, plays a pivotal role in modern industrial production. Its remarkable strength, hardness, corrosion resistance, workability, and weldability make it widely applicable in fields such as marine engineering, petrochemicals, and aerospace. In this article, let’s take a closer look at Monel 400 alloy characteristics and its applications.

Monel 400 Alloy Characteristics and Its Applications:

Firstly, in terms of corrosion resistance, Monel 400 alloy primarily comprises nickel and copper, with small additions of iron, manganese, silicon, and other elements. These alloying elements endow it with exceptional corrosion resistance, particularly against various acidic media like sulfuric acid, hydrofluoric acid, hydrochloric acid, phosphoric acid, organic acids, as well as alkaline media and saline solutions.

Secondly, in terms of strength and hardness, Monel 400 alloy boasts high levels in both aspects. Its tensile strength ranges approximately from 550 to 880 MPa, while its yield strength lies between 240 and 520 MPa. The alloy also exhibits a broad range of hardness values, typically within HRB 82-90, enabling it to adapt to diverse working scenarios and application requirements.

Furthermore, Monel 400 alloy possesses excellent workability. With good ductility and an elongation rate usually between 20% and 35%, it can be formed into various shapes and sizes through various processing techniques. However, it’s crucial to note that during machining, this alloy material undergoes contraction, necessitating careful attention to machining allowances to ensure dimensional accuracy of the workpieces.

Additionally, Monel 400 alloy, being a solid-solution-strengthened alloy, exhibits favorable welding properties. It is amenable to multiple welding methods, including TIG and MIG welding. Nevertheless, given its high nickel and copper content, it’s crucial to choose welding wires and electrodes with a chemical composition identical to the base metal to ensure high joint strength after welding.

Lastly, in terms of application, Monel 400 alloy’s superior corrosion resistance, particularly against chlorides and salts in marine environments, renders it ideal for marine engineering applications like marine heat exchangers, desalination equipment, and salt production facilities. Moreover, in the petrochemical industry, its outstanding corrosion resistance and mechanical properties make it a preferred choice for manufacturing piping, valves, pumps, reactors, and other equipment.

Conclusion

In conclusion, Monel 400 alloy, as a high-performance alloy, fulfills demanding application requirements across various harsh environments thanks to its exceptional hardness, corrosion resistance, workability, and weldability. From marine engineering to petrochemicals, Monel 400 alloy plays a vital role in ensuring the safety and reliability of various equipment and components.

Why Choose Huaxiao Alloy?

Thank you for reading our article and we hope it can help you to have a better understanding of Monel 400 alloy characteristics and its applications. If you are looking for suppliers and manufacturers of Monel alloys, we would advise you to visit Huaxiao Alloy for more information.

As a leading supplier of Monel alloys from Shanghai China, Huaxiao Alloy offers customers high-quality Monel 400 and Monel K500 at a very competitive price.