As an outstanding nickel-iron alloy material, Inconel 718 boasts remarkable properties such as high-temperature strength, corrosion resistance, fatigue resistance, and workability, making it an indispensable material in fields like aerospace, petrochemicals, energy, and marine engineering. In this article, we will take a closer look at the performance and applications of Inconel 718 alloy.

Performance and Applications of Inconel 718 Alloy:

Firstly, in the aerospace industry, Inconel 718 excels in its high-temperature strength, with a melting point of up to 1320°C, enabling it to maintain excellent mechanical properties in extreme temperature environments. Consequently, it has become a popular choice for critical components in aerospace equipment such as aircraft engines, jet propulsion systems, and turbine assemblies, ensuring the long-term stable operation of aerospace devices.

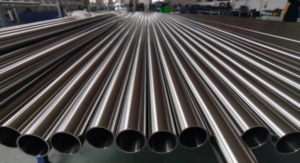

Secondly, in the petrochemical sector, Inconel 718 distinguishes itself with its unique chemical composition and physical properties that effectively resist corrosion from various substances, including acids, alkalis, and salts. Its outstanding corrosion resistance and high-temperature performance make it suitable for applications in the petroleum processing process, where it can withstand high temperatures, pressures, and corrosive media. As a result, Inconel 718 is utilized in the manufacture of transportation pipelines, reactors, valves, and other equipment, ensuring their stable operation in harsh corrosive environments and extending their service life.

Furthermore, Inconel 718 plays a vital role in the energy industry. The sector often involves high-temperature, high-pressure, and highly corrosive environments, necessitating materials with exceptional fatigue resistance. Thanks to its excellent fatigue resistance, Inconel 718 can operate reliably under cyclic loads, making it suitable for use in energy equipment such as nuclear reactors, gas turbines, steam turbines, and heat exchangers, thereby enhancing equipment safety and reliability.

Additionally, Inconel 718 boasts good workability, allowing for various processing methods like forging, rolling, and welding to form it into different shapes and sizes. In the marine engineering field, this versatility enables Inconel 718 to be utilized in the manufacturing of ocean drilling platforms, ships, and subsea equipment, providing essential material support for the exploration and utilization of marine resources.

Conclusion

In conclusion, Inconel 718 alloy, with its exceptional high-temperature strength, corrosion resistance, fatigue resistance, and workability, plays a pivotal role in aerospace, petrochemicals, energy, and marine engineering. As technology advances and industries evolve, Inconel 718 alloy is poised to enjoy an even broader range of applications, offering a safe and reliable material foundation for the development of modern industries.

Why Choose Huaxiao Alloy?

Thank you for reading our article and we hope it can help you to have a better understanding of the performance and applications of Inconel 718 alloy. If you are looking for suppliers and manufacturers of Inconel 718 alloy, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Inconel alloy from Shanghai China, Huaxiao Alloy offers customers high-quality Inconel 718 alloy at a very competitive price.