What is aluminum-zinc coated steel?

- July 29, 2024

- 6:24 pm

- 430

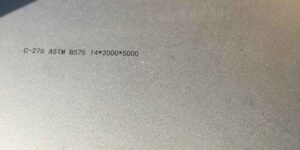

Aluminum-zinc coated steel is an aluminum-zinc alloy structure composed of 55% aluminum, 43% zinc and 2% silicon solidified at a high temperature of 600 ℃ and composed of the entire structure of aluminum – iron – silicon – zinc, forming a dense tetrameric crystals of an alloy. Aluminum-zinc-plated steel plate is an important alloy material often used in daily life.

Product properties of aluminum-zinc coated steel

Aluminum-zinc-plated steel sheet has a number of excellent characteristics: strong corrosion resistance, 3 times that of pure galvanized sheet; beautiful zinc flowers on the surface, which can be used as a building exterior sheet.

Corrosion resistance of aluminum-zinc coated steel

The corrosion resistance of “Aluminum Zinc Plated Steel Coil” is mainly due to the protective function of aluminum. When zinc is abraded, aluminum forms a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior.

Heat Resistance of aluminum-zinc coated steel

Aluminum-zinc alloy steel sheet has good heat resistance and can withstand temperatures of more than 300 degrees Celsius, very similar to the resistance to high-temperature oxidation of aluminum-plated steel sheet, and is often used for chimney pipes, ovens, luminaires and fluorescent light covers.

Thermal Reflectivity of aluminum-zinc coated steel

Aluminum-zinc coated steel has a high thermal reflectivity, twice that of galvanized steel, and is often used as an insulating material.

applications of aluminum-zinc coated steel

Construction: roofs, walls, garages, soundproof walls, ducts, and modular houses, etc.

Automobiles: mufflers, exhaust pipes, wiper attachments, fuel tanks, truck boxes, etc.

Home Appliances: refrigerator back panel, gas stove, air conditioner, electronic microwave oven, LCD bezel, CRT explosion-proof belt, LED backlight, electrical cabinet, etc.

Agricultural: pigsties, chicken coops, grain bins, greenhouse pipes, etc.

Others: heat insulation cover, heat exchanger, dryer, water heater, etc.

Precautions for use

Storage: It should be stored indoor in the warehouse, keep dry and ventilated, do not leave it in the acidic climate for a long time. Outdoor storage should be prevented from rain, to avoid condensation caused by oxidative discoloration.

Transportation: Avoid external impacts, use SKID to support the steel coils on the means of transportation, reduce stacking, and take measures against rain.

Processing: Use the same lubricant as used for aluminum plates when processing with COILCENTER shear. When drilling or cutting aluminum-zinc-plated steel plate, remove the scattered iron chips in time.

Using aluminum and galvanized steel together can lead to galvanic corrosion if not properly managed. Galvanic corrosion occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte, leading to the more anodic metal (aluminum) corroding more rapidly. However, with appropriate precautions, these materials can be used together.

Aluminum galvanized steel is not a common term, but it can refer to galvanized steel that has been coated with a zinc-aluminum alloy, such as Galvalume. This coating combines aluminum’s excellent corrosion resistance with zinc’s sacrificial properties, providing enhanced protection for steel.

To prevent galvanic corrosion between aluminum and galvanized steel:

- Insulate the Metals: Use non-conductive materials like rubber or plastic gaskets to separate the metals physically.

- Use Protective Coatings: Apply coatings such as paint, anodizing, or powder coatings to one or both metals to prevent direct contact.

- Cathodic Protection: Apply a sacrificial anode or impressed current to protect the more anodic metal.

- Sealants: Use sealants to keep moisture out of the joint between the two metals.

Galvanized steel coils are steel sheets that have been coated with zinc to prevent rust and corrosion. The steel is passed through a bath of molten zinc in a process known as hot-dip galvanizing, which forms a durable and protective zinc layer. These coils are used in various applications such as roofing, automotive parts, appliances, and structural supports.

- Aluminum: Aluminum forms a protective oxide layer that prevents further oxidation and rusting. It doesn’t rust in the traditional sense but can corrode under certain conditions.

- Galvanized Steel: Galvanized steel resists rusting due to the protective zinc coating. However, over time and under harsh conditions, the zinc layer can wear away, leading to rust formation on the underlying steel.

GI (Galvanized Iron/Steel):

- Coating: Pure zinc coating.

- Corrosion Resistance: Good corrosion resistance due to the zinc coating.

- Applications: Roofing, fencing, automotive parts, and various construction materials.

Aluzinc:

- Coating: A combination of zinc (43.4%), aluminum (55%), and silicon (1.6%).

- Corrosion Resistance: Superior corrosion resistance compared to pure galvanized steel, especially in harsh environments.

- Heat Reflectivity: Better heat reflectivity due to the aluminum content.

- Applications: Roofing, cladding, and structural components requiring high corrosion resistance.

If you found this article good, feel free to share it on your other social media platforms.