What is hot-dip galvanized sheet?

- July 29, 2024

- 12:25 am

- 1681

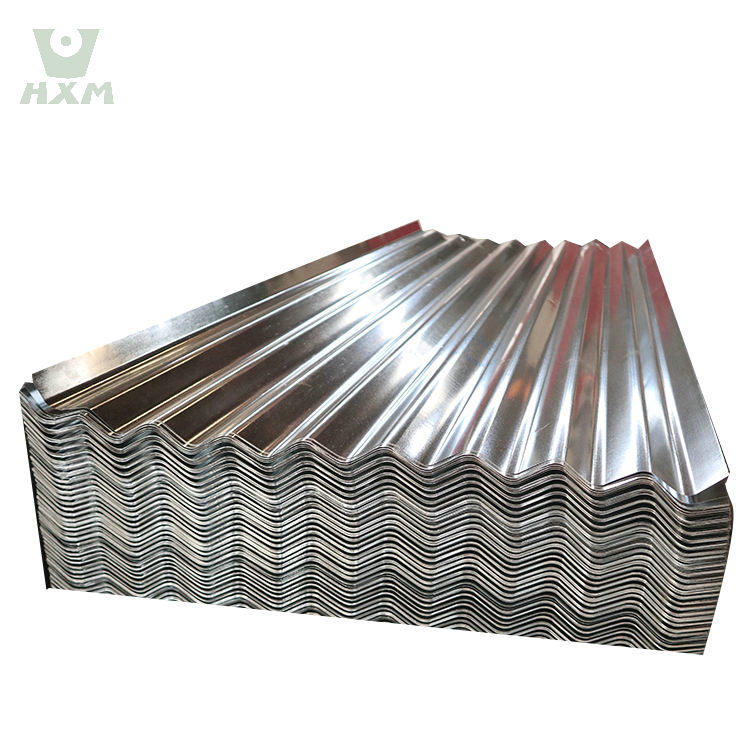

Hot-dip galvanized sheet refers to a steel sheet that has been coated with a layer of zinc through the hot-dip galvanizing process. This process involves immersing the steel sheet in a bath of molten zinc to create a corrosion-resistant coating.

Commonly used steel grades

Commonly used steel grades for hot-dip galvanized sheet include: general commercial coil (CQ), structural galvanized sheet (HSLA), stamped galvanized sheet (DQ) deep-dip hot-dip galvanized sheet (DDQ), bake-hardened hot-dip galvanized sheet (BH), dual-phase steel (DP), and TRIP steel (phase-change-induced plasticity steel).

Composition and Process of hot-dip galvanized sheet

- Base Material: The base material is typically carbon steel or low alloy steel.

- Zinc Coating: The steel sheet is dipped into a bath containing molten zinc at a temperature of approximately 450°C (842°F).

- Formation of Layers: The zinc coating forms a metallurgical bond with the steel, creating a series of zinc-iron alloy layers topped with a layer of pure zinc.

Benefits and Properties of hot-dip galvanized sheet

- Corrosion Resistance: The primary advantage of hot-dip galvanizing is the enhanced corrosion resistance provided by the zinc coating. This coating acts as a barrier protecting the steel from moisture and oxygen, which can cause rust and corrosion.

- Durability: The zinc coating is robust and can withstand mechanical damage, making the sheet durable for various applications.

- Self-Healing: Zinc has a self-healing property, where minor scratches or damages can be covered by zinc oxide, maintaining protection against corrosion.

- Extended Life Span: The galvanized coating extends the life span of the steel sheet significantly, especially in harsh environments.

Applications of hot-dip galvanized sheet

Hot-dip galvanized sheets are widely used in various industries due to their excellent properties. Common applications include:

- Construction: Used for roofing, siding, structural components, and facades due to its durability and aesthetic appeal.

- Automotive: Utilized in the manufacturing of automobile bodies, frames, and other components to enhance corrosion resistance.

- HVAC: Employed in heating, ventilation, and air conditioning systems for ductwork and components.

- Agriculture: Used for fencing, grain silos, and other agricultural equipment exposed to the elements.

- Electrical: Applied in the production of electrical boxes, panels, and conduits.

Standards and Specifications of hot-dip galvanized sheet

Hot-dip galvanized sheets are produced according to various international standards to ensure quality and performance. Some common standards include:

- ASTM A653 / A653M: Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process.

- EN 10346: Continuously Hot-Dip Coated Steel Flat Products.

- JIS G3302: Japanese Industrial Standard for Hot-Dip Zinc-Coated Steel Sheet and Strip.

Conclusion

Hot-dip galvanized sheet is a versatile and durable product with superior corrosion resistance, making it suitable for a wide range of applications. Its protective zinc coating, formed through the hot-dip galvanizing process, ensures a long life span and reliable performance in various environments.

The primary ASTM standard for hot-dip galvanizing is ASTM A123/A123M. This specification covers the requirements for zinc coatings applied by the hot-dip process on iron and steel products. It includes details on coating thickness, adhesion, and other properties.

Composition:

- Hot-Dipped Galvanized Steel: This is steel coated with a layer of zinc to protect against corrosion. The process involves dipping the steel in molten zinc.

- Stainless Steel: This is an alloy containing a minimum of 10.5% chromium, which provides inherent corrosion resistance through the formation of a passive oxide layer.

Corrosion Resistance:

- Hot-Dipped Galvanized Steel: The zinc coating provides a barrier that prevents corrosive substances from reaching the steel. It is sacrificial, meaning it will corrode over time to protect the underlying steel.

- Stainless Steel: The chromium in stainless steel reacts with oxygen to form a protective layer of chromium oxide, which prevents further corrosion.

Applications:

- Hot-Dipped Galvanized Steel: Used in construction, automotive, and agricultural sectors for items like guardrails, bridges, and outdoor structures.

- Stainless Steel: Used in applications requiring superior corrosion resistance, such as kitchen appliances, medical instruments, and chemical processing equipment.

Hot-dip galvanized steel does not have a single grade like stainless steel. Instead, it refers to the process of applying a zinc coating to steel. The properties of galvanized steel can vary depending on the base steel used. Common base steels include structural grades like ASTM A36 or high-strength low-alloy grades like ASTM A572.

Yes, hot-dip galvanized steel can eventually rust, but it has a significantly extended lifespan compared to uncoated steel. The zinc coating provides a sacrificial layer that corrodes first, protecting the underlying steel. The longevity of the protection depends on the environment and thickness of the zinc coating.

- Galvanized Steel: Generally refers to steel that has been coated with zinc to prevent rusting. This can include both electro-galvanized and hot-dip galvanized methods.

- Hot-Dipped Galvanized Steel: Specifically refers to the process where steel is submerged in molten zinc to form a thick, durable coating. This method provides better corrosion resistance compared to electro-galvanizing.

The ISO standard for hot-dip galvanized coatings is ISO 1461. This standard specifies the requirements for the thickness and appearance of hot-dip galvanized coatings on fabricated iron and steel articles. It includes guidelines for testing and quality control to ensure consistency and reliability.

If you found this article good, feel free to share it on your other social media platforms.