What is NAS64?

- July 31, 2024

- 1:07 am

- 528

NAS64 is a highly corrosion-resistant stainless steel developed by our company, whose chemical composition and physical properties allow it to excel in a wide range of corrosive environments.

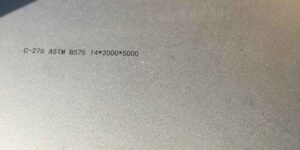

Specifically, NAS 64 (also known as SUS 329J4L or UNS S32506) is an austenitic-ferritic duplex stainless steel with a primary composition consisting of 25Cr, 6.5Ni, 3.3Mo and 0.17N.

This material has very high corrosion resistance and is particularly suitable for resistance to phosphoric acid, acetic acid and various sulphur compounds. Due to its high chromium and molybdenum content, it performs particularly well in localised corrosion

. However, as its oxide skin is more difficult to remove, it is recommended that it be treated with a short alkaline soak prior to pickling, or that the results be improved by shot peening.

NAS 64 is widely used in scenarios that require anti-pollution equipment, petrochemical equipment, paper making sets, seawater treatment equipment, and sluice gates. This material not only has excellent corrosion resistance, but also can cope with a variety of harsh industrial environments to ensure the long-term stable operation of the equipment.

Excellent corrosion resistance of NAS64

NAS 64 is a stainless steel material with excellent corrosion resistance that outperforms common high corrosion resistant stainless steels such as SUS 304 and 316L in a number of ways.

1.Resistant to erosion and pitting corrosion

- NAS 64 significantly outperforms SUS 304 and 316L in terms of erosion and pit corrosion resistance, and based on the evidence, NAS 64’s erosion and pit corrosion resistance is far superior to that of other materials, including SUS 304 and 316L.

SUS 304 and 316L. In addition, NAS 64 has more than twice the pitting corrosion resistance of SUS 329J1, and its crevice corrosion resistance far exceeds that of SUS 304 and 316L. - In terms of chemical composition and physical properties, SUS 304, which consists primarily of chromium (Cr) and nickel (Ni), has good corrosion resistance and formability, and maintains stable corrosion resistance in most environments. However, although SUS 304 performs well in many corrosive environments, especially in chloride environments, its corrosion resistance is still not as good as NAS 64.

2.SUS 316L

Regarding SUS 316L, although it contains more molybdenum (Mo) than SUS 304, which improves its resistance to pitting and crevice corrosion, NAS 64 still performs better in these areas. Especially for extreme conditions that cannot withstand the corrosive environment of 316L, NAS 64 offers a better solution.

Application of NAS64

1.Machines for the prevention of public hazards

- Thanks to its excellent corrosion resistance, NAS 64 is used in the manufacture of machines for the prevention of public hazards, which are usually exposed to seawater or salty environments.

2.Petrochemical and petrochemical plants

- In these industrial environments, NAS 64 is used in a wide range of equipment due to its ability to resist harsh chemical environments and corrosion.

Fibre Manufacturing Facilities

3.Fibre Manufacturing Facilities

- In textile and fibre production processes, NAS 64 is selected for its corrosion resistance to ensure the long-term stable operation of the equipment.

4.Paper mill equipment

- In the paper industry, NAS 64 is also used for its excellent corrosion resistance in a variety of paper manufacturing equipment.

Geothermal Power Generation Equipment

5.Geothermal Power Generation Equipment

- As geothermal power generation equipment is often exposed to high temperatures and pressures, NAS 64’s high strength and corrosion resistance make it an ideal choice.

6.Water gates and oil well pipes

- In these applications, NAS 64 not only provides the necessary strength, but also ensures long-term corrosion resistance, thus extending the life of the equipment.

7.Desalination plants

- Compared to other materials, NAS 64 offers better resistance to localised corrosion and is therefore particularly suitable for desalination plants.

NAS stainless steel refers to the stainless steels produced by Nippon Yakin, a Japanese manufacturer. These steels are often identified by their NAS designation and include a variety of grades tailored for specific properties and uses, such as corrosion resistance, strength, or heat resistance. Common types include NAS 304, NAS 316, and NAS 430.

AL-6XN stainless steel is a super-austenitic stainless steel with high nickel, molybdenum, and nitrogen content, which enhances its resistance to chloride pitting and crevice corrosion. It doesn’t have a direct equivalent in standard stainless steel grades but can be compared to other super-austenitic steels like UNS N08367 or similar to 254 SMO (S31254).

The “best” version of stainless steel depends on the specific application. For general corrosion resistance, 316L is highly regarded. For high strength and heat resistance, alloys like 17-4PH or 440C are preferred. For extreme environments, super-austenitic, duplex, or super-duplex grades might be suitable.

The hardest stainless steels are typically the martensitic stainless steels, such as 440C and 420, which are hardened by heat treatment. These steels are used in applications requiring high strength and wear resistance, like cutlery and bearings.

The most expensive stainless steels are usually the more complex alloys, such as duplex and super-duplex stainless steels, or highly alloyed super-austenitic grades like AL-6XN. Their high content of nickel and other alloying elements like molybdenum significantly increases their cost.

The cheapest grades of stainless steel are typically the ferritic stainless steels, like 430, which have lower nickel content and are used in less corrosive environments. These steels are commonly used in automotive applications and kitchen utensils.

Recent Blog

If you found this article good, feel free to share it on your other social media platforms.