In the realm of metal alloys, Hastelloy C4 vs C22 occupies a unique niche, renowned for their exceptional corrosion resistance and durability in hostile environments. Both alloys belong to the Hastelloy family, a group of nickel-based alloys designed to withstand extreme conditions such as high temperatures, oxidizing environments, and corrosive media. However, despite their similarities, Hastelloy C4 and C22 exhibit distinct characteristics that make them suitable for different applications.

Hastelloy C4 vs C22 – What’s the Difference?

Let’s delve into the intricacies of these alloys and explore the key differences between Hastelloy C4 and C22.

Hastelloy C4 vs C22 – Composition and Chemical Properties

Hastelloy C4, also known as UNS N06455, is primarily composed of nickel, chromium, molybdenum, and iron. Its nickel content is significantly high, providing a solid foundation for corrosion resistance. Chromium and molybdenum add to its ability to withstand oxidizing and reducing acids, respectively. On the other hand, Hastelloy C22, or UNS N06022, has a slightly different composition, with a higher concentration of molybdenum and the addition of tungsten. This tweaked composition enhances its resistance to pitting and crevice corrosion in chloride-containing environments.

Hastelloy C4 vs C22 – Corrosion Resistance

Both Hastelloy C4 and C22 exhibit excellent corrosion resistance, but their specific performance depends on the type of corrosive media encountered. Hastelloy C4 is renowned for its resistance to oxidizing acids such as nitric acid and sulfuric acid. It also performs well in reducing environments containing hydrochloric acid. However, in chloride-rich environments, Hastelloy C4 may be susceptible to pitting and crevice corrosion.

Hastelloy C22, on the other hand, offers superior resistance to pitting and crevice corrosion in chloride-containing solutions, making it a preferred choice for applications involving seawater or brine. Its high molybdenum and tungsten content contribute to this enhanced corrosion resistance. Therefore, Hastelloy C22 is often used in marine environments, desalination plants, and other areas where chloride corrosion is a concern.

Hastelloy C4 vs C22 – Mechanical Properties

The mechanical properties of Hastelloy C4 and C22 also differ slightly. Hastelloy C4 typically exhibits higher tensile strength and yield strength compared to C22. This makes it a suitable choice for applications that require high strength and durability. However, Hastelloy C22 offers superior ductility and toughness, allowing it to withstand deformation and impact better. This enhanced ductility is beneficial in applications where flexibility and formability are crucial.

Hastelloy C4 vs C22 – Fabrication and Weldability

Both Hastelloy C4 and C22 can be fabricated using conventional methods such as hot and cold working, machining, and forming. However, their weldability characteristics differ. Hastelloy C4 is generally easier to weld due to its lower tendency to form weld cracks. It also exhibits good post-weld corrosion resistance. On the contrary, Hastelloy C22 requires special welding techniques and consumables to minimize the risk of weld cracking and ensure optimal corrosion resistance. Preheat and post-weld heat treatment may also be necessary to ensure the integrity of the welded joint.

Hastelloy C4 vs C22 – Applications

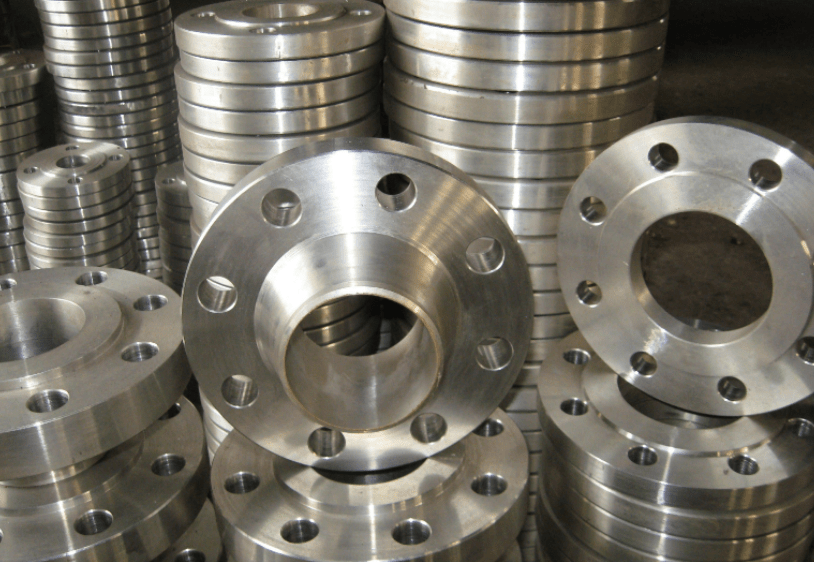

The distinct characteristics of Hastelloy C4 and C22 dictate their specific applications. Hastelloy C4 is commonly used in chemical processing equipment, pollution control systems, and other industries where resistance to oxidizing acids is crucial. Its high strength and good corrosion resistance make it a reliable choice for these demanding environments.

Hastelloy C22, on the other hand, finds widespread use in marine applications, desalination plants, and oil and gas production facilities. Its superior resistance to chloride-induced corrosion makes it ideal for handling seawater, brine, and other chloride-rich media. The alloy’s excellent ductility and toughness also contribute to its suitability in these often-demanding applications.

Conclusion

In summary, Hastelloy C4 and C22 are both exceptional alloys with unique properties that cater to different industrial needs. Hastelloy C4 excels in resistance to oxidizing acids and offers high strength, making it suitable for chemical processing and related industries. Hastelloy C22, on the other hand, stands out in its resistance to chloride-induced corrosion, making it the preferred choice for marine and other chloride-rich environments.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between Hastelloy C4 vs C22. If you are looking for Hastelloy C4 & C22 supplier and manufacturer online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Hastelloy Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality Hastelloy C4 & C22, Hastelloy G50 Alloy, Hastelloy D205, Hastelloy G30 (UNS N06030), Hastelloy C-2000, Hastelloy B2, Hastelloy X alloy, and Hastelloy C-276 at a very competitive price.

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Dutch

Dutch English

English French

French German

German Italian

Italian Japanese

Japanese Korean

Korean Malayalam

Malayalam Mongolian

Mongolian Norwegian

Norwegian Portuguese

Portuguese Russian

Russian Serbian

Serbian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish