High Temperature Alloy

High temperature alloy is a special type of alloy that is capable of maintaining excellent mechanical properties and stability in high-temperature environments.High temperature alloys usually contain elements such as nickel, iron and cobalt, as well as some other alloying elements such as chromium, tungsten and molybdenum.

High temperature alloy has excellent resistance to high-temperature oxidation, corrosion and creep, and can work stably for a long time under extreme temperatures and harsh environments. It is widely used in aerospace, energy, chemical industry and other fields for the manufacture of engine parts, high-temperature furnaces, petrochemical equipment and other key components.

Due to the excellent performance and reliability of high-temperature alloys, it has become an indispensable and important material in modern industry.

Grades of High Temperature Alloy

Advantages of High Temperature Alloy

The unique benefits of Incoloy alloys are mainly in the following areas:

1.High temperature strength:

Incoloy alloys have excellent high-temperature strength and can maintain stable mechanical properties at extremely high temperatures. The chromium and aluminum elements in its composition effectively increase the alloy’s high temperature strength and heat resistance.

2.Antioxidant performance:

Incoloy alloy has excellent antioxidant performance, can effectively resist oxidation in high temperature environment. The dense oxide film formed on the surface protects the interior of the alloy from corrosion and oxidation.

3.Corrosion Resistance:

Incoloy alloys have excellent corrosion resistance and are capable of resisting corrosion in a variety of harsh environments. The chromium element in its composition provides excellent corrosion resistance, while the aluminum element also provides excellent corrosion resistance.

4.Processing performance:

Because of the good processing performance of the Kolloy alloy, it can be easily cut, bending, drilling and other processing operations. The surface quality after machining is relatively high.

5.Welding properties:

Inconel has good welding properties and can be joined by various welding processes. This allows for more flexible application of Inkroy alloys in the manufacturing process, improving productivity.

In summary, the unique benefits of Inkroy alloys make them a superior high-temperature material, distinguishing them from other specialty alloys. Its excellent performance in high-temperature strength, oxidation resistance, corrosion resistance, machinability and weldability has led to a wide range of applications for Incoloy alloys in aerospace, energy and automotive fields, providing an important support for the development of modern industry.

Relevant Blogs

What’s Another Name for Hastelloy?

Hastelloy is a registered trademark of Haynes International, Inc., and refers to a family of nickel-based superalloys known for their exceptional resistance to corrosion, high temperature, and stress. These alloys are commonly used in chemical processing, aerospace, and marine applications due to their durability in extreme environments.

While Hastelloy is the widely recognized name, there are a few other ways people may refer to these materials. Here’s another name for Hastelloy and classifications that relate to Hastelloy alloys:

Chemical Composition and Performance Advantages of Hastelloy B-2 Alloy

Hastelloy B-2 alloy, a superior nickel-based superalloy, is widely utilized across various industries such as aviation, aerospace, petrochemicals, and chemicals

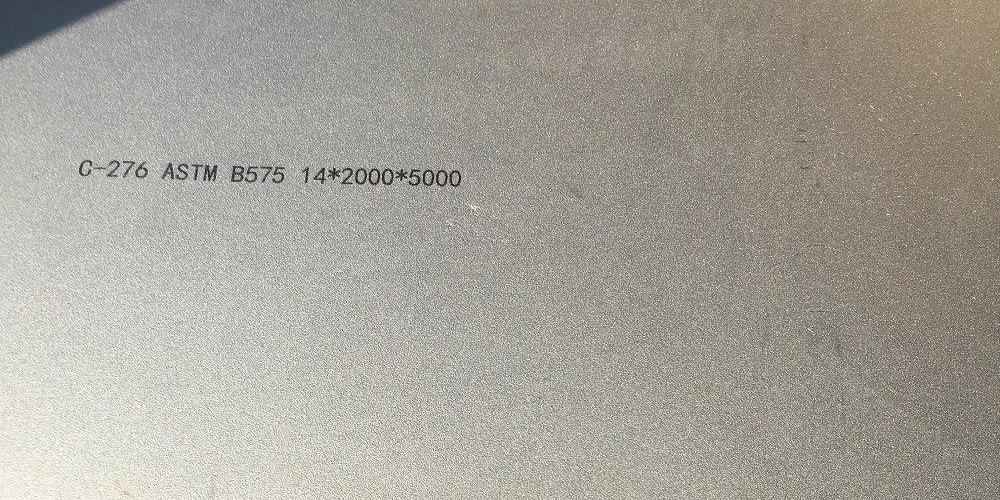

Composition and Characteristics of Hastelloy C-276 Alloy

Hastelloy C-276 alloy, as a high-performance alloy material, stands out for its exceptional corrosion resistance and high-temperature strength, enabling it

Optimization of Manufacturing Processes for Hastelloy Alloys

Hastelloy alloys, a class of high-performance nickel-based alloys, play a pivotal role in numerous industries due to their exceptional corrosion

High-Temperature Properties and Applications of C-2000 Hastelloy Alloy

C-2000 Hastelloy alloy, a nickel-based superalloy comprising nickel, molybdenum, chromium, and other elements, plays a pivotal role in modern industrial

Welding Characteristics and Precautions of Hastelloy

Hastelloy, a high-temperature alloy composed of nickel, cobalt, copper, and other elements, is widely used in aerospace, petrochemical, marine engineering,