In the realm of high-performance alloys, Incoloy 825 vs Hastelloy C276 occupies prominent positions, each boasting unique properties and applications. While both alloys are renowned for their corrosion resistance and strength, they differ significantly in composition, characteristics, and the environments where they excel. In this article, we aim to provide a detailed and authoritative comparison between Incoloy 825 and Hastelloy C276, highlighting their differences in terms of composition, properties, and industrial uses.

Incoloy 825 vs Hastelloy C276 – What’s the Difference?

Incoloy 825 vs Hastelloy C276 – Composition

Incoloy 825, also known as UNS N08825, is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. Its nickel content is significant, typically ranging from 47 to 53%, providing excellent corrosion resistance in a wide range of environments. The addition of molybdenum enhances its resistance to pitting and crevice corrosion, while copper and titanium contribute to its stability and weldability.

On the other hand, Hastelloy C276, or UNS N10276, is a nickel-molybdenum-chromium alloy with added tungsten. Its nickel content is even higher, typically around 57%, making it even more resistant to corrosion. The high molybdenum content, coupled with tungsten, provides superior resistance to oxidizing and reducing acids, making it ideal for handling highly corrosive media.

Incoloy 825 vs Hastelloy C276 – Properties

Both alloys exhibit excellent corrosion resistance, but their specific properties vary depending on the environmental conditions. Incoloy 825 demonstrates good resistance to sulfuric and phosphoric acids, as well as to chloride-containing environments. It also exhibits good weldability and formability, allowing it to be easily fabricated into complex shapes.

Hastelloy C276, on the other hand, is renowned for its exceptional resistance to hydrochloric, sulfuric, and nitric acids, even at elevated temperatures. This alloy also demonstrates excellent resistance to stress corrosion cracking and pitting corrosion, making it a top choice for handling harsh chemicals and acids.

In terms of mechanical properties, both alloys possess high strength and good ductility. However, Hastelloy C276 tends to have slightly higher tensile strength and yield strength than Incoloy 825, making it more suitable for applications that require superior structural integrity.

Incoloy 825 vs Hastelloy C276 – Applications

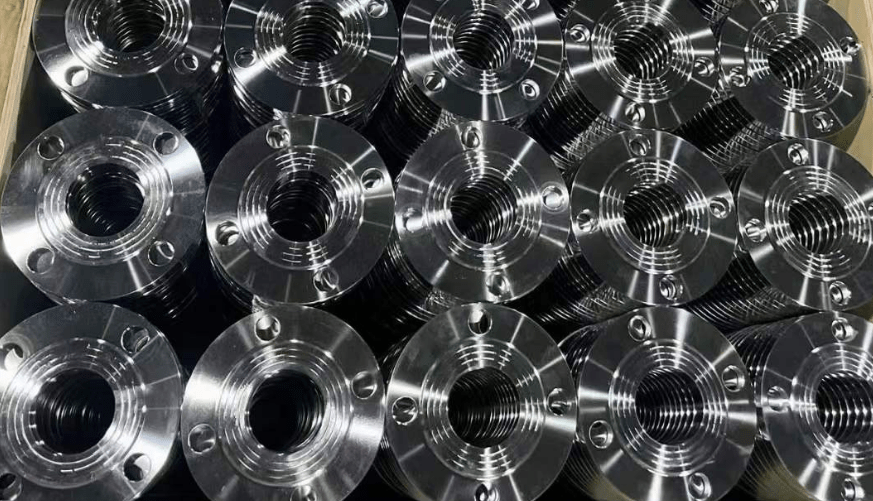

The choice between Incoloy 825 and Hastelloy C276 often depends on the specific application and the corrosive environment involved. Incoloy 825 is commonly used in oil and gas production, chemical processing, and power generation, where it is exposed to sulfuric and phosphoric acids, as well as chloride-containing media. Its good weldability and formability also make it suitable for manufacturing complex components and structures.

Hastelloy C276, on the other hand, is widely used in the chemical processing industry, particularly in handling highly corrosive acids such as hydrochloric and sulfuric acid. It is also employed in pulp and paper production, pollution control, and waste treatment, where its exceptional corrosion resistance and strength are critical.

Incoloy 825 vs Hastelloy C276 – Cost Considerations

It is worth noting that Hastelloy C276 typically costs more than Incoloy 825 due to its higher nickel content and more complex manufacturing process. This cost difference can be significant, especially in large-scale projects where the quantity of material required is substantial. Therefore, when considering these alloys for a specific application, it is important to weigh the cost against the performance requirements and the expected lifetime of the material.

Conclusion

Incoloy 825 and Hastelloy C276 are both outstanding alloys with unique properties and applications. Incoloy 825 excels in environments containing sulfuric and phosphoric acids, offering good weldability and formability. Hastelloy C276, on the other hand, demonstrates exceptional resistance to a wide range of corrosive acids, making it ideal for handling harsh chemicals and acids.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between Incoloy 825 vs Hastelloy C276. If you are looking for Incoloy 825 & Hastelloy C276 alloy suppliers and manufacturers online now, we advise you to visit Huaxiao Alloy.

As a leading supplier of Incoloy and Hastelloy Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality Incoloy 825 & Hastelloy C276 alloy, Hastelloy C4 & C22, Hastelloy G50 Alloy, Hastelloy D205, Hastelloy G30 (UNS N06030), Hastelloy C-2000, Hastelloy B2, and Hastelloy X alloy at a very competitive price.

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Dutch

Dutch English

English French

French German

German Italian

Italian Japanese

Japanese Korean

Korean Malayalam

Malayalam Mongolian

Mongolian Norwegian

Norwegian Portuguese

Portuguese Russian

Russian Serbian

Serbian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish