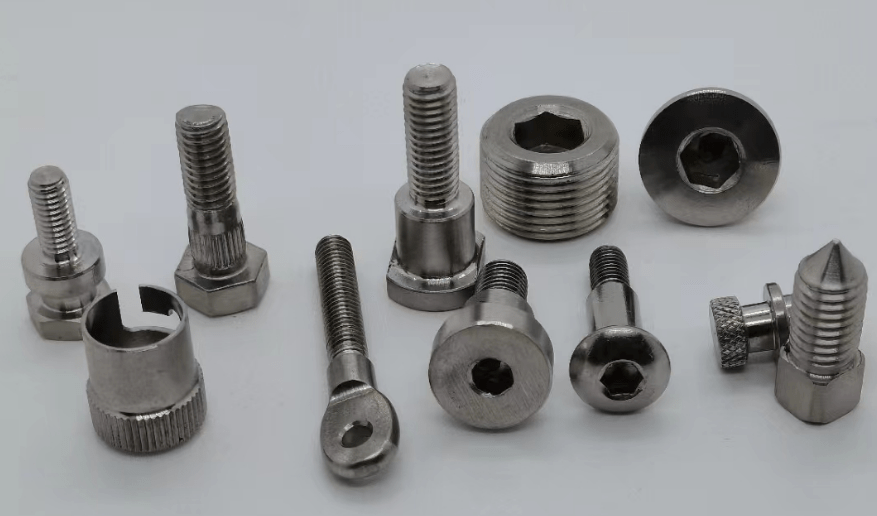

Monel 400, a nickel-copper alloy, has earned a reputation as a reliable and durable material for fasteners in a wide range of industries. Its unique composition and exceptional properties make it stand out among other metals, especially in high-stress and corrosive environments. In this comprehensive article, we will delve into the intricacies of Monel 400 fasteners, discussing their composition, properties, and the diverse applications where they excel.

Monel 400 Fasteners – Composition, Properties and Uses

Composition of Monel 400 Fasteners

Monel 400 fasteners are composed primarily of nickel and copper, with nickel being the dominant element. This alloy typically contains approximately 63-67% nickel, 28-33% copper, and trace amounts of other elements such as iron, manganese, and silicon. The addition of these trace elements modifies the alloy’s properties, enhancing its mechanical strength and corrosion resistance.

The nickel content in Monel 400 gives it excellent resistance to chloride stress corrosion cracking, making it suitable for use in saltwater and other chloride-rich environments. The copper component adds to the alloy’s corrosion resistance and also improves its ductility and weldability.

Properties of Monel 400 Fasteners

- Corrosion Resistance: Monel 400 fasteners exhibit exceptional resistance to corrosion in a wide range of environments, including saltwater, acidic solutions, and high-temperature environments. This makes them ideal for use in marine applications, chemical processing equipment, and other demanding environments.

- Strength and Ductility: The alloy’s combination of nickel and copper provides it with high strength and ductility, making it suitable for use in fasteners that require both strength and flexibility.

- High-Temperature Resistance: Monel 400 maintains its mechanical properties even at elevated temperatures, making it suitable for use in high-temperature applications.

- Ease of Fabrication: The alloy can be easily formed, welded, and machined, making it suitable for a wide range of manufacturing processes.

- Magnetic Properties: Monel 400 is non-magnetic, which is beneficial in certain applications where magnetic interference is undesirable.

Uses of Monel 400 Fasteners

Monel 400 fasteners find applications in a diverse range of industries due to their unique combination of properties. Some of the primary uses of Monel 400 fasteners include:

- Marine Applications: Monel 400’s resistance to corrosion in saltwater environments makes it an ideal choice for fasteners used in marine equipment, such as pumps, valves, and piping systems.

- Chemical Processing Industry: The alloy’s resistance to corrosion in acidic solutions makes it suitable for use in fasteners for chemical reactors, storage tanks, and other equipment used in the chemical processing industry.

- Oil and Gas Industry: Monel 400 fasteners are often used in oil and gas exploration and production equipment due to their resistance to corrosion and high-temperature performance.

- Aerospace Industry: The alloy’s strength, ductility, and high-temperature resistance make it suitable for use in fasteners for aircraft engines and other aerospace components.

Conclusion

In conclusion, Monel 400 fasteners, with their unique composition and exceptional properties, are an invaluable material for a wide range of applications. Their corrosion resistance, strength, ductility, and ease of fabrication make them a preferred choice for fasteners in marine, chemical processing, oil and gas, and aerospace industries.

Thank you for reading our article and we hope it can help you to have a better understanding of Monel 400 fasteners. If you are looking for Monel 400 fastener suppliers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of high-temperature alloys from Shanghai China, Huaxiao Alloy offers customers Monel 400, Monel K500, Inconel 602 alloy, Hastelloy S Alloy, Inconel Alloy 600, Inconel Alloy 601, Inconel 625 UNS N06625, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), and Hastelloy C-2000 at a very competitive price.