Monel 500, a nickel-copper alloy, has been a trusted material in various industries for decades due to its exceptional corrosion resistance and mechanical properties. As a seasoned expert in Monel alloys from Huaxiao Alloy, I am delighted to provide an overview of Monel 500 composition, focusing on its accuracy, professionalism, detail, and authority.

Monel 500 Composition – An Overview

The primary components of Monel 500 are nickel and copper, with nickel accounting for the majority of the alloy’s composition. Nickel, a silvery-white metal, is renowned for its high corrosion resistance and excellent mechanical properties. In Monel 500, nickel’s presence contributes significantly to the alloy’s ability to withstand corrosive environments, particularly those involving seawater and certain acids.

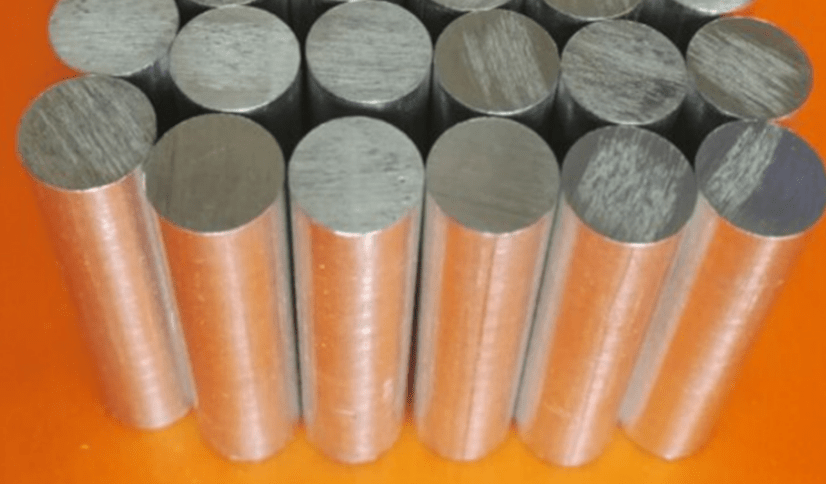

Copper, the second major constituent of Monel 500, is a ductile and malleable metal with excellent electrical conductivity. In this alloy, copper enhances the mechanical properties, such as tensile strength and ductility, allowing for easier processing and fabrication. The combination of nickel and copper in Monel 500 creates a unique microstructure that contributes to the alloy’s overall performance.

Apart from nickel and copper, Monel 500 may also contain small amounts of other elements, such as iron, manganese, carbon, and sulfur, added to fine-tune the alloy’s properties or meet specific manufacturing requirements. These trace elements, while present in minor quantities, can have a significant impact on the alloy’s microstructure and, consequently, its corrosion resistance and mechanical behavior.

The precise composition of Monel 500 is carefully controlled during the manufacturing process to ensure consistent and predictable material properties. The alloy is typically produced through melting and casting techniques, followed by hot and cold working operations to achieve the desired shape and size. Strict quality control measures are employed throughout the manufacturing process to guarantee the alloy’s compositional accuracy and consistency.

The corrosion resistance of the Monel 500 is one of its most notable features. The alloy’s ability to withstand corrosion in various environments, including seawater, saltwater, and many chemical solutions, makes it a popular choice for marine applications, chemical processing, and other industries where corrosion is a significant concern. Additionally, Monel 500’s good mechanical properties, such as high tensile strength and ductility, allow it to perform well in structural applications that require both strength and corrosion resistance.

The combination of these properties, coupled with Monel 500’s excellent weldability and formability, makes it a versatile material suitable for a wide range of applications. From marine hardware and chemical processing equipment to electrical components and plumbing fixtures, Monel 500 finds its way into numerous industries where its unique properties are highly valued.

Conclusion

In conclusion, Monel 500, with its precise composition of nickel and copper, along with trace elements, offers a unique set of properties that cater to specific industrial needs. Its corrosion resistance, mechanical properties, and fabricability make it a reliable and trusted material in various applications.

Thank you for reading our article and we hope it can help you to have a better understanding of Monel 500 composition. If you are looking for Monel Alloy suppliers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality Monel products such as Monel 500 Alloy, and Monel 400 Alloy at a very competitive price.