When it comes to selecting the right material for a particular application, understanding the nuances between similar options is crucial. Monel K500 vs Monel 400, both renowned for their exceptional corrosion resistance, often face off in material selection decisions. But Monel K500 vs Monel 400 – what’s the difference? In this article, we delve into the specific characteristics and properties of Monel K500 and Monel 400.

Monel K500 vs Monel 400 – What’s the Difference?

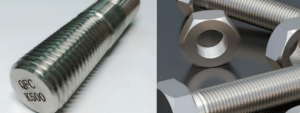

Monel K500 and Monel 400 are both Monel alloys with excellent corrosion resistance, but there are some important differences between them.

Firstly, the strength and hardness of Monel K500 are higher than those of Monel 400. This is because Monel K500 contains more copper and aluminum elements, which play an important role in improving strength and hardness.

Secondly, the corrosion resistance of Monel K500 is also better than that of Monel 400. Due to its higher copper content, it has a stronger tolerance to certain chemicals, especially in acidic environments such as sulfuric acid and phosphoric acid.

Additionally, the welding performance of the Monel K500 is better than that of the Monel 400. Because of its higher alloy content, it is easier to weld and the strength after welding remains higher.

Finally, the processing performance of Monel K500 is slightly better than that of Monel 400. Although their processing characteristics are similar, Monel K500 has lower requirements for heat treatment during processing, making its processing process easier.

Overall, both Monel K500 and Monel 400 are excellent corrosion-resistant alloys, but in terms of strength, welding performance, and corrosion resistance, Monel K500 has a slight advantage.

Monel K500 vs Monel 400 – Applications:

Monel 400 alloy is a multi-purpose material that can be used in many industrial fields:

- Power plant seamless water pipes and steam pipes;

- Sea water exchangers and evaporators;

- Sulfuric acid and hydrochloric acid environments;

- Crude oil distillation;

- Pump shafts and propellers for sea water equipment;

- Manufacture of pumps and valves for hydrochloric acid equipment;

Applications of Monel K-500 Products:

- Used for manufacturing turbine blades and gas turbine blades that operate at temperatures below 750℃ on aero engines;

- 2. Used for manufacturing fasteners and springs on ships; pump and valve components in chemical equipment; scraper on paper-making equipment; used for pump shafts and impellers, conveyor scrapers, oil well drill collars, elastic parts, valve gaskets, etc.

- Other applications include the manufacture of various heat exchange equipment, boiler feed water heaters, petroleum and chemical pipelines, containers, towers, tanks, valves, pumps, reactors, shafts, etc. Due to its low corrosion rate in flowing seawater and the high strength of this alloy, Monel K500 is suitable for manufacturing centrifugal pump shafts that are resistant to seawater. It is suitable for static and flowing seawater.

Why Choose Huaxiao Alloy?

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between Monel K500 vs Monel 400. If you want to learn more about Monel K500 and Monel 400, we would advise you to visit Huaxiao Alloy for more information.

As a leading supplier of Monel Alloys from China, Huaxiao Alloys provides customers with high-quality Monel K500 and Monel 400, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), Hastelloy C-2000, Hastelloy B2, Hastelloy X alloy, Hastelloy C4, Hastelloy C-276, and Hastelloy C22 at a very competitive price.