Many of our customers have such a question: Monel K500 vs Stainless Steel 316 – What’s the difference? Both of these alloys are widely used in different industries due to their unique properties and characteristics. In this article, we will delve into the differences between the Monel K500 and Stainless Steel 316, providing an accurate, professional, detailed, and authoritative comparison.

Monel K500 vs Stainless Steel 316 – What’s the Difference?

Monel K500 vs Stainless Steel 316 – 1. Monel K500

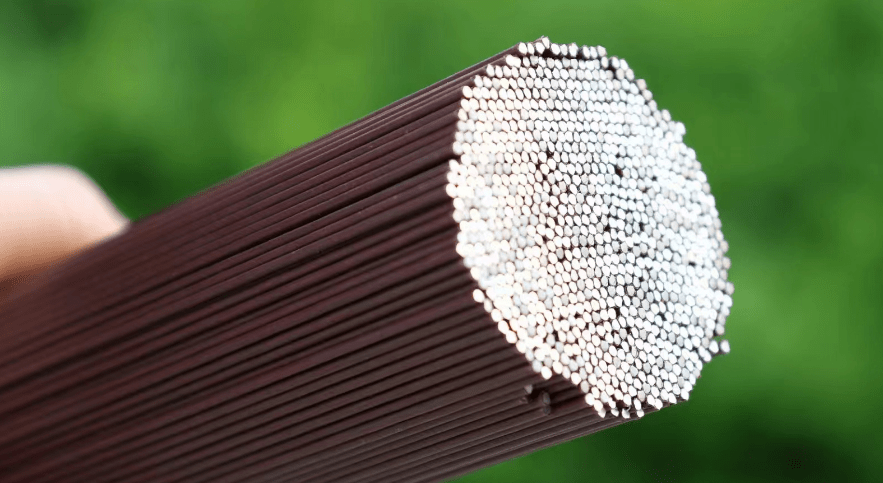

Monel K500 is a nickel-copper alloy that offers exceptional resistance to corrosion in a wide range of environments. It is primarily composed of nickel (about 67%) and copper (about 29%), with smaller amounts of aluminum and titanium added to enhance its mechanical properties.

One of the key features of Monel K500 is its high strength and ductility, which make it suitable for use in demanding applications where both corrosion resistance and mechanical performance are crucial. It is commonly used in the chemical processing industry, marine environments, and oil and gas exploration due to its resistance to chloride-ion stress-corrosion cracking.

Monel K500 also exhibits good weldability and can be easily formed and machined into complex shapes. However, it is important to note that Monel K500 has a lower thermal conductivity than other metals, which can affect welding and machining processes.

Monel K500 vs Stainless Steel 316 – 2. Stainless Steel 316

Stainless Steel 316 is an austenitic stainless steel grade that contains a higher level of chromium and nickel compared to other stainless steel grades. It also has a small amount of molybdenum added to improve its resistance to corrosion, especially in chloride-rich environments.

Stainless Steel 316 is widely used in applications that require high corrosion resistance, such as marine environments, chemical processing, and medical equipment. Its high chromium content forms a protective oxide layer on the surface, known as the passivation layer, which prevents oxygen and water from reaching the underlying steel, thus preventing rust formation.

In addition to its corrosion resistance, Stainless Steel 316 offers good strength, ductility, and weldability. It is also relatively easy to form and machine, making it a popular choice for a wide range of industrial applications.

Monel K500 vs Stainless Steel 316 – 3. Differences

- Composition: Monel K500 is primarily a nickel-copper alloy, while Stainless Steel 316 is an austenitic stainless steel with a high chromium and nickel content.

- Corrosion Resistance: Both materials offer excellent corrosion resistance, but Monel K500 has superior resistance to chloride-ion stress-corrosion cracking, making it more suitable for use in harsher environments.

- Mechanical Properties: Monel K500 typically exhibits higher strength and ductility than Stainless Steel 316, making it more suitable for applications that require both corrosion resistance and high mechanical performance.

- Weldability and Fabrication: Both materials can be welded and machined relatively easily, but Monel K500 has a lower thermal conductivity, which can affect welding and machining processes.

- Cost: Stainless Steel 316 is generally more cost-effective than Monel K500 due to its more widespread use and availability.

Conclusion

In summary, Monel K500 vs Stainless Steel 316 are both excellent materials with unique properties and applications. The choice between them depends on the specific requirements of the application, such as the severity of the corrosive environment, the required mechanical properties, and the budget considerations.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between Monel K500 vs Stainless Steel 316. If you are looking for Monel K500 suppliers online now, we would advise you to contact Huaxiao Alloy.

As a leading supplier of Monel K500 products from Shanghai China, Huaxiao Alloy provides customers with high-quality alloys such as Monel K500 and Monel 400, Inconel 602 alloy, Hastelloy S Alloy, Inconel Alloy 600, Inconel Alloy 601, Inconel 625 UNS N06625, Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), and Hastelloy C-2000 at a very competitive price.