4J32 Expansion Alloy(super invar alloy)

4J32 alloy, also known as Invar alloy (Super-Invar), exhibits a lower coefficient of thermal expansion than 4J36 alloy within the temperature range of -60 to 80°C, though it has less structural stability at low temperatures compared to 4J36. This alloy is primarily used in manufacturing high-precision instrument components where dimensional stability is essential across varying ambient temperatures.

Standard Dimensions of 4J32 Expansion Alloy in Various Forms

| Form | Thickness / Diameter | Width | Length |

|---|---|---|---|

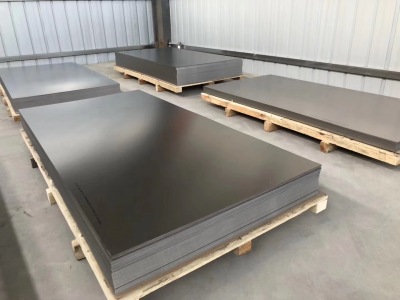

| 4J32 Expansion Alloy Sheets(invar – controlled expansion alloy sheet) | 0.3 mm – 5 mm | 100 mm – 1000 mm | 500 mm – 2000 mm |

| 4J32 Expansion Alloy Plates(super invar plate) | 5 mm – 50 mm | 200 mm – 1200 mm | 500 mm – 3000 mm |

| 4J32 Expansion Alloy Round Bars(super invar bar) | 3 mm – 150 mm diameter | – | 1000 mm – 6000 mm |

| 4J32 Expansion Alloy Flat Bars | 3 mm – 50 mm thickness | 20 mm – 200 mm | 1000 mm – 3000 mm |

| 4J32 Expansion Alloy Wires(invar – controlled expansion alloy wire) | 0.1 mm – 10 mm diameter | – | Coil or custom lengths |

| 4J32 Expansion Alloy Tubes | 1 mm – 50 mm outer diameter | – | 500 mm – 3000 mm |

Huaxiao Alloy is a professional 4J32 alloy supplier(super invar alloy), dedicated to providing high-quality and reliable special alloy materials. We are certified with SGS: ISO 9001, ensuring that every batch meets international quality standards. If you have special alloy requirements, Huaxiao Alloy is your most trusted choice. We guarantee the most competitive prices—contact us now for more information and expert support!

Chemical composition of 4J32

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 31.0 – 33.0 |

| Iron (Fe) | Balance |

| Cobalt (Co) | 4.5 – 5.5 |

| Manganese (Mn) | 0.80 max |

| Silicon (Si) | 0.30 max |

| Carbon (C) | 0.05 max |

| Phosphorus (P) | 0.020 max |

| Sulfur (S) | 0.020 max |

Corresponding and Similar Grades to 4J32 Expansion Alloy Alloy

| Standard | Grade | Description |

|---|---|---|

| China (GB/T) | 4J32 | Low-expansion alloy with stability |

| USA (ASTM) | Nilo 32 | Similar expansion properties to 4J32 |

| Germany (DIN) | W.Nr 1.3912 | Nickel-iron alloy with controlled expansion |

| Japan (JIS) | Pernifer 32 | Equivalent nickel-iron expansion alloy |

| France (AFNOR) | Fe-Ni 32 | Low-expansion alloy, similar to 4J32 |

| UK (BS) | Invar 32-5 | Used in high-precision applications |

Our company maintains strong cooperative relationships with many well-known domestic enterprises, such as Taigang (TISCO) and JISCO. We have advanced technology and production equipment, and our metal products have passed international quality standard certifications.(SGS ISO 9001)

We offer a wide variety of alloy products to meet your diverse needs. You can choose from different shapes and grades of alloys. With a large inventory of metal products, we can quickly fulfill your order requirements.

Huaxiao Alloy is a trusted alloy metel supplier. Our team provides full support from pre-sales to after-sales services. Our 24/7 customer service ensures that your needs are always taken care of. We are here to solve any issues related to your alloy material requirements at any time!

Physical Properties of 4J32 Alloy

The melting temperature range of 4J32 is 1430–1450°C. Its thermal conductivity is λ = 13.9 W/(m•°C). The linear expansion coefficient is specified as α1 (20–100°C) ≤ 1.0×10⁻⁶ °C⁻¹. Similar to 4J36, 4J32 achieves its maximum linear expansion coefficient when annealed above 850°C. Faster cooling rates can reduce the linear expansion coefficient, and for α1 (room temperature to 100°C), quenching can lower it by nearly half compared to annealing.

Special Treatment Procedure for 4J32

To ensure low expansion coefficient and structural stability at low temperatures, the performance test samples are processed and heat-treated as follows: Semi-finished samples are heated to 840°C ± 10°C, held for 1 hour, water-quenched, then processed into finished samples and held at 315°C ± 10°C for 1 hour, followed by furnace cooling or air cooling.

Applications and Special Requirements of 4J32

4J32 is a typical low-expansion alloy with stable performance, validated by long-term use in the aerospace industry. It is primarily used in manufacturing high-precision components where dimensional stability is required across varying environmental temperatures. Strict control over heat treatment and machining processes is essential, with structural stability checks based on operational temperature.

Structure of 4J32 Alloy

After treatment following the specified procedure, 4J32 alloy should not exhibit martensite structure even when cooled at -60°C for 2 hours. However, if the alloy composition is inappropriate, transformation from austenite (γ) to needle-like martensite (α) may occur at ambient or low temperatures, causing volume expansion. The main factor affecting the low-temperature structural stability of 4J32 alloy is its chemical composition. Nickel is the primary element stabilizing the γ-phase, with higher nickel content promoting γ-phase stability. Copper also stabilizes the alloy’s structure, and the alloy’s structure becomes more stable as total deformation rate increases. Additionally, composition segregation can lead to local γ→α phase transformation, and coarse grains can further promote this transformation.

Welding Properties of 4J32

4J32 alloy can be welded by brazing, fusion welding, and resistance welding. Due to the alloy’s sensitivity to changes in chemical composition, argon arc welding is preferred to maintain the stability of its expansion coefficient.

Heat Treatment Process for 4J32 Components

The heat treatment process for 4J32 includes stress-relief annealing, intermediate annealing, and stabilization treatment.

- Stress-Relief Annealing: To remove residual stresses from machining, heat to 530–550°C, hold for 1–2 hours, then furnace cool.

- Intermediate Annealing: To eliminate work hardening from cold rolling, drawing, or stamping, heat to 830–880°C, hold for 30 minutes, then furnace cool or air cool.

- Stabilization Treatment: Ensures low expansion coefficient and stabilizes performance using a three-stage process:

- Homogenization: Heats the alloy to 830°C in a protective atmosphere for 20 minutes to 1 hour, then quenches.

- Tempering: Heats the alloy to 315°C for 1–4 hours, then furnace cools to relieve stress from quenching.

- Stabilization Aging: Maintains dimensional stability by heating to 95°C and holding for 48 hours.

- For high-precision parts that have undergone cold or mechanical processing, use low-temperature stress relief at 315–370°C for 1–4 hours.

Surface Treatment of 4J32

Surface treatments for 4J32 alloy include sandblasting, polishing, or pickling. It can be pickled with a 25% hydrochloric acid solution at 70°C to remove oxide scale.

Machinability and Grindability of 4J32

The machinability of 4J32 alloy is similar to that of austenitic stainless steel. Low-speed machining is recommended with high-speed steel or carbide tools, and a coolant may be used. The alloy also has good grindability.