4J36 Expansion Alloy

4J36 is a special low-expansion iron-nickel alloy with an ultra-low coefficient of expansion. The control of carbon and manganese composition is very important in it. Cold deformation reduces the coefficient of thermal expansion and heat treatment in a specific temperature range stabilizes the coefficient of thermal expansion. In dry air at room temperature 4J36 is corrosion resistant. In other harsh environments, such as humid air, corrosion (rust) may occur.

Standard Dimensions of 4J36 Expansion Alloy in Various Forms

| Form | Thickness / Diameter | Width | Length |

|---|---|---|---|

| 4J36 Expansion Alloy Sheets | 0.3 mm – 5 mm | 100 mm – 1000 mm | 500 mm – 2000 mm |

| 4J36 Expansion Alloy Plates | 5 mm – 50 mm | 200 mm – 1200 mm | 500 mm – 3000 mm |

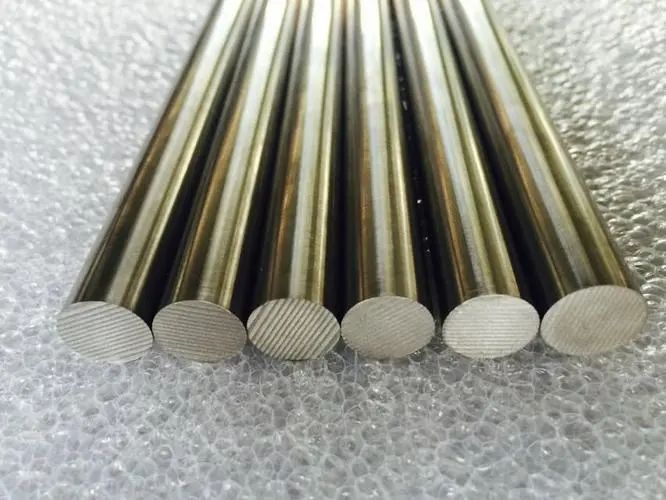

| 4J36 Expansion Alloy Round Bars | 3 mm – 150 mm diameter | – | 1000 mm – 6000 mm |

| 4J36 Expansion Alloy Flat Bars | 3 mm – 50 mm thickness | 20 mm – 200 mm | 1000 mm – 3000 mm |

| 4J36 Expansion Alloy Wires | 0.1 mm – 10 mm diameter | – | Coil or custom lengths |

| 4J36 Expansion Alloy Tubes | 1 mm – 50 mm outer diameter | – | 500 mm – 3000 mm |

Chemical composition of 4J36 Expansion Alloy

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 35.0 – 37.0 |

| Iron (Fe) | Balance |

| Carbon (C) | 0.05 max |

| Manganese (Mn) | 0.60 max |

| Silicon (Si) | 0.30 max |

| Phosphorus (P) | 0.020 max |

| Sulfur (S) | 0.020 max |

| Chromium (Cr) | 0.25 max |

| Cobalt (Co) | 0.50 max (optional) |

Corresponding and Similar Grades to 4J36 Expansion Alloy

| Standard | Grade | Description |

|---|---|---|

| China (GB/T) | 4J36 | Standard Chinese designation for Invar 36 |

| USA (ASTM) | UNS K93600, Invar | Low-expansion nickel-iron alloy |

| Germany (DIN) | W.Nr 1.3912 | Nickel-iron alloy with low thermal expansion |

| Japan (JIS) | Pernifer 36 | Low-expansion alloy similar to Invar 36 |

| France (AFNOR) | Fe-Ni36 | Alloy for low-expansion, matching Invar 36 |

| UK (BS) | Nilo 36 | Low-expansion alloy used in precision applications |

Our company maintains strong cooperative relationships with many well-known domestic enterprises, such as Taigang (TISCO) and JISCO. We have advanced technology and production equipment, and our metal products have passed international quality standard certifications.(SGS ISO 9001)

We offer a wide variety of alloy products to meet your diverse needs. You can choose from different shapes and grades of alloys. With a large inventory of metal products, we can quickly fulfill your order requirements.

Huaxiao Alloy is a trusted alloy metel supplier. Our team provides full support from pre-sales to after-sales services. Our 24/7 customer service ensures that your needs are always taken care of. We are here to solve any issues related to your alloy material requirements at any time!

Physical Properties of 4J36 Alloy

- Density: ρ = 8.1 g/cm³

- Melting Point: 1430°C

- Curie Temperature: 230°C

- Specific Heat Capacity: 515 J/kg·K

Application Areas of 4J36 Alloy

4J36 is applied in environments requiring an extremely low coefficient of thermal expansion, including the following fields:

Production, Storage, and Transportation of Liquefied Gas

4J36 alloy is used in liquefied gas applications where stable dimensional properties at low temperatures are essential.Measurement and Control Instruments Below +200°C

It is suitable for precision measurement and control devices such as temperature regulators, which require dimensional stability under low to moderate temperature conditions.Bushings for Screw Connectors Between Metals and Other Materials

The alloy is used as bushings in screw connectors, facilitating reliable connections between metal and non-metal materials where thermal expansion differences need to be minimized.Bimetal and Thermostatic Bimetals

4J36 is often employed in the production of bimetal and thermostatic bimetal components due to its stable expansion properties.Tempering Molds for CRP Components in the Aerospace Industry

It is used in tempering molds for CRP (Carbon Reinforced Polymer) components in the aerospace industry, ensuring precision in high-stress environments.Electronic Control Unit Frames in Satellites and Missiles Below -200°C

4J36 alloy is applied in structural frames of electronic control units for satellites and missiles, where temperatures fall below -200°C, requiring low-expansion materials for stability.Auxiliary Electron Tubes in Electromagnetic Lenses for Laser Control Devices

The alloy is used in auxiliary electron tubes in electromagnetic lenses within laser control devices, providing stability and precision in sensitive optical applications.

Low Thermal Expansion

- Feature: 4J36 is renowned for its extremely low coefficient of thermal expansion (CTE) from room temperature up to approximately 200°C. This characteristic makes it unique among alloys and ideal for applications where temperature-induced size changes must be minimized.

- Impact: The low thermal expansion ensures stability in precision instruments and optical devices, where even minor dimensional changes could affect functionality and accuracy.

Magnetic Properties

- Curie Temperature: The Curie temperature of 4J36 is around 230°C. Above this temperature, the alloy loses its ferromagnetic properties and becomes paramagnetic.

- Applications: This property is beneficial in certain applications where magnetic properties need to be controlled or where the material must remain non-magnetic beyond certain operational temperatures.

Mechanical Properties

- Elastic Modulus: 4J36 has an elastic modulus of approximately 141 GPa, providing good stiffness and structural integrity in its applications.

- Machinability: The alloy is relatively easy to machine, similar to austenitic stainless steels. This makes it suitable for manufacturing complex components that require precision and stability.

- Formability: 4J36 can be formed into various shapes and thicknesses, such as sheets, plates, wires, tubes, and bars, offering flexibility for different design needs.

Heat Treatment

- Stabilization: 4J36 requires heat treatment to achieve optimal dimensional stability. Stabilization is usually performed at temperatures between 200°C and 300°C to minimize internal stresses and maintain low thermal expansion properties.

- Annealing: Annealing at around 800°C can improve the alloy’s ductility and further stabilize its properties.

- Cryogenic Treatment: To improve dimensional stability, 4J36 may also undergo cryogenic treatment, especially in applications that require operation at very low temperatures.

Corrosion Resistance

4J36 has moderate corrosion resistance, comparable to stainless steel in many environments. However, it is not as corrosion-resistant as higher-alloyed stainless steels. In moist or slightly acidic environments, it is advisable to apply protective coatings or use protective storage to enhance durability.

Weldability

- Method: 4J36 can be welded using common welding techniques, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding.

- Precautions: Due to the alloy’s low expansion properties, care must be taken to minimize thermal stress during welding. Post-weld heat treatment is often recommended to relieve stress and maintain stability in high-precision applications.