Hastelloy Strip / Precision Strip

Product Grades:Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy X, Hastelloy B-2, Hastelloy B-3, W.Nr. 2.4819, 2.4602, 2.4675, 2.4617, UNS N06022, N10276, N06200, N06002, N10665.

Implementation Standards:ASTM B575, ASME SB575.

Certification:ISO9001:2015.

Features:Hastelloy strips offer exceptional corrosion resistance in oxidizing and reducing environments, with high strength and stability under extreme conditions. They also resist pitting, crevice corrosion, and stress cracking effectively.

Applications:Ideal for chemical processing, pollution control, aerospace, marine industries, and power generation equipment like heat exchangers and boilers.

MOQ:500 KG.

Payment Methods:T/T, LC.

Price:Negotiable.

Hastelloy Strip / Precision Strip Supplier

Hastelloy Strips, Precision Strips, ASTM B575 Hastelloy Strips, Hastelloy Alloy Coils, Hastelloy Slitting Strips, Hastelloy Perforated Strips Supplier in China.

Hastelloy Cold Rolled Strips, ASTM B575 Hastelloy Precision Strips, Hastelloy Alloy Strips Exporter, Hastelloy Strips Dealer Worldwide.

Huaxiao Alloy, a trusted supplier and exporter based in China, specializes in providing a wide range of Hastelloy Alloy Strips and Precision Strips to global clients. Our high-quality Hastelloy products are renowned for their superior corrosion resistance, high strength, and durability under extreme conditions. Produced in state-of-the-art facilities, our strips are rigorously tested to ensure compliance with international standards such as ASTM B575 and ASME SB575.

We offer Hastelloy Alloy Strips in various grades, sizes, and specifications to meet diverse industrial requirements. Customization options are available to suit specific client needs, ensuring reliable performance in critical applications.

Specifications for Hastelloy Strip / Precision Strip

| Category | Thickness Range | Width Range | Length Range | Standard Specifications |

|---|---|---|---|---|

| Hastelloy Strips | 0.1 mm – 4.0 mm | 10 mm – 600 mm | Coil Lengths (as required) | ASTM B575, ASME SB575 |

| Hastelloy Coils | 0.1 mm – 6.0 mm | 10 mm – 2000 mm | Coil Lengths (as required) | ASTM B575, ASME SB575 |

| Precision Strips | 0.1 mm – 2.0 mm | 10 mm – 300 mm | Coil Lengths (as required) | ASTM B575, ASME SB575 |

- Standards: ASTM B575, ASME SB575.

- Forms: Strips, Precision Strips, Coils.

- Surface Finishes: 2B, BA, No.4, Mirror, HL (Hairline), Satin.

- Hardness Levels: Soft, Half Hard, Quarter Hard, Full Hard.

- Applications: Ideal for chemical processing, aerospace, marine, pollution control, and power generation equipment.

Available Hastelloy Grades

We supply the following grades of Hastelloy alloy strips and precision strips:

- Hastelloy C22 (UNS N06022 / W.Nr. 2.4602): Superior resistance to oxidizing and reducing environments, ideal for mixed chemical conditions.

- Hastelloy C276 (UNS N10276 / W.Nr. 2.4819): Widely used in severe chemical environments with excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

- Hastelloy C2000 (UNS N06200 / W.Nr. 2.4675): Enhanced versatility in both oxidizing and reducing conditions, making it suitable for diverse industrial applications.

- Hastelloy B2 (UNS N10665 / W.Nr. 2.4617): Exceptional resistance to hydrochloric acid and other highly reducing chemicals.

- Hastelloy B3 (UNS N10675 / W.Nr. 2.4600): Improved thermal stability and resistance to localized corrosion, particularly in aggressive chemical processes.

- Hastelloy X (UNS N06002 / W.Nr. 2.4665): Excellent high-temperature strength and oxidation resistance, ideal for aerospace and industrial heating applications.

- Hastelloy G30 (UNS N06030 / W.Nr. 2.4603): Superior performance in oxidizing acids, particularly phosphoric acid environments.

- Hastelloy G35 (UNS N06035): Designed for outstanding resistance to oxidizing environments with high chloride levels.

Key Features of Hastelloy Strip

Exceptional Corrosion Resistance

- Outstanding resistance to both oxidizing and reducing environments, making it ideal for handling aggressive chemicals.

- Excellent protection against pitting, crevice corrosion, and stress corrosion cracking in extreme conditions.

High-Temperature Stability

- Maintains mechanical strength and stability at elevated temperatures, suitable for high-heat industrial applications.

- Reliable performance under thermal cycling and in oxidizing atmospheres.

Superior Mechanical Properties

- High strength and durability under extreme pressure and environmental conditions.

- Excellent formability and machinability, allowing for precise manufacturing.

Versatile Surface Finishes

- Available in 2B, BA, No.4, Mirror, and Hairline finishes to meet various industrial needs and aesthetic preferences.

Customizable Dimensions

- Offered in a wide range of thicknesses (0.1 mm to 4.0 mm) and widths (10 mm to 600 mm), tailored to customer requirements.

Applications Across Critical Industries

- Essential for chemical processing, pollution control, marine, aerospace, and power generation applications where performance and reliability are critical.

Applications of Hastelloy Strip / Precision Strip

Chemical Processing

- Used in heat exchangers, reactors, and chemical storage tanks for handling highly corrosive substances like hydrochloric acid, sulfuric acid, and chlorine-based chemicals.

- Ideal for flanges, gaskets, and precision components in aggressive chemical environments.

Pollution Control Systems

- Essential for flue gas scrubbers, ducting systems, and waste treatment equipment exposed to acidic and corrosive byproducts.

- Reliable in environmental equipment used for handling pollutants and emissions.

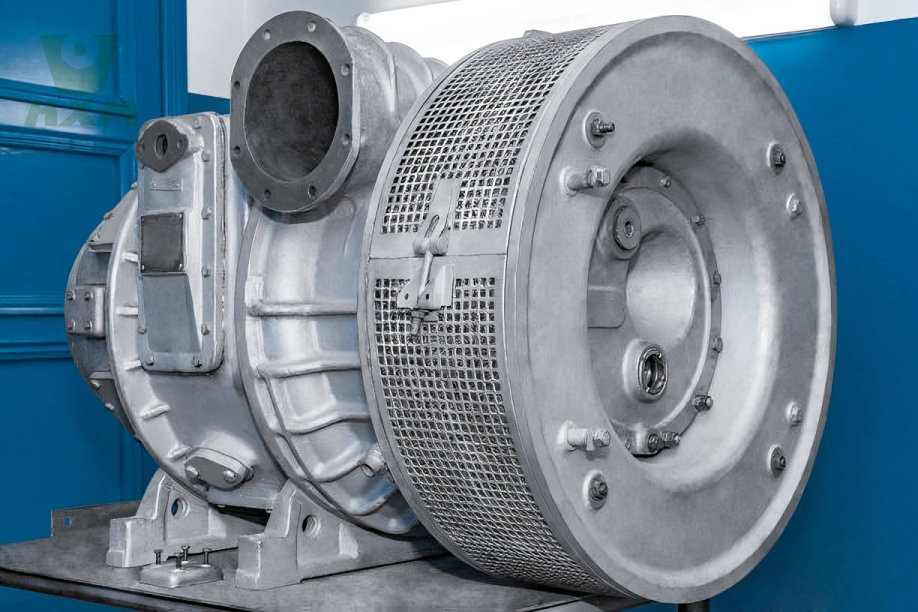

Aerospace Industry

- Applied in high-temperature components such as turbine engine parts, exhaust ducts, and combustion chambers.

- Ensures reliability and durability under extreme thermal conditions.

Marine Applications

- Suitable for seawater systems, desalination plants, and brine heaters due to its excellent resistance to chloride-induced corrosion.

- Used in marine engineering for components exposed to harsh saltwater environments.

Power Generation

- Used in heat recovery systems, boiler components, and high-temperature piping in nuclear and conventional power plants.

- Provides long-term reliability in high-pressure and high-temperature conditions.

Electronics and Precision Equipment

- Used in manufacturing components requiring high precision, stability, and corrosion resistance, such as sensors and micro-components.

- Suitable for critical electronic equipment in harsh industrial environments.

Pharmaceutical and Food Processing

- Ensures contamination-free operations in equipment used for high-purity substances.

- Ideal for sterile environments where corrosion resistance is essential.

Hastelloy strips and precision strips are indispensable in industries demanding superior corrosion resistance, high-temperature stability, and long-lasting performance. Let me know if you need further refinement or customization!

Packaging & Delivery

Packaging Options:

- Bundles with plastic wrapping for weather protection.

- Wooden crates or pallets for safe transportation.

- Custom packaging available based on client requirements.

Delivery Time: 10-25 days or faster if stock is available.

Why Choose Huaxiao Alloy?

Expertise in Alloy Materials:

Huaxiao Alloy is a trusted supplier of Hastelloy Strips and Precision Strips, with extensive expertise in producing high-quality nickel-based alloys tailored to meet demanding industrial needs.Comprehensive Product Range:

We offer a wide variety of Hastelloy grades, including C-22, C-276, C-2000, X, B-2, and B-3, with customizable thicknesses, widths, and finishes to suit specific applications.Stringent Quality Assurance:

All products undergo rigorous testing to comply with international standards such as ASTM B575 and ASME SB575, ensuring consistent performance and reliability.Advanced Manufacturing Capabilities:

Utilizing state-of-the-art facilities, we ensure precision processing, including cold rolling, slitting, and edge finishing, to meet the highest industry requirements.Global Export Expertise:

Trusted by clients across Europe, the Americas, Asia, and the Middle East, Huaxiao Alloy is known for timely delivery and exceptional customer service in the global market.Competitive Pricing and Customization:

Our products are offered at competitive prices without compromising quality, with flexible customization options to meet the unique requirements of your project.

Contact us today to learn more or to request a quote for Hastelloy Strips and Precision Strips!

Get Quote Now for Hastelloy Strip / Precision Strip

FAQs

Yes, Alloy 22 and C22 refer to the same material, officially known as Hastelloy C-22 (UNS N06022 / W.Nr. 2.4602). It is a nickel-chromium-molybdenum-tungsten alloy designed for exceptional corrosion resistance in oxidizing and reducing environments. The terms “Alloy 22” and “C22” are commonly used interchangeably in the industry.

The choice between Hastelloy C22 and Hastelloy C276 depends on the application:

Corrosion Resistance:

- C22: Superior resistance to oxidizing agents (e.g., nitric acid, ferric ions, and chlorides).

- C276: Better suited for reducing conditions (e.g., hydrochloric acid, sulfuric acid).

Versatility:

- C22: More versatile, offering protection in both oxidizing and reducing environments.

- C276: Primarily used in reducing environments.

Applications:

- C22: Ideal for mixed chemical environments and applications involving strong oxidizers.

- C276: Preferred for highly reducing environments or when resistance to localized corrosion is critical.

Conclusion: Choose C22 for versatility and superior performance in mixed environments, and C276 for specialized use in strongly reducing environments.

Yes, Alloy C276 is a Hastelloy, specifically Hastelloy C-276 (UNS N10276 / W.Nr. 2.4819). It is a nickel-molybdenum-chromium alloy with excellent corrosion resistance in reducing environments, including resistance to strong acids, pitting, and stress-corrosion cracking. It is one of the most widely used Hastelloy grades in industries like chemical processing, marine, and pollution control.

Hastelloy:

- A trademarked name for a group of corrosion-resistant nickel-based alloys manufactured by Haynes International.

- Known for superior performance in extreme chemical and thermal environments, especially in oxidizing and reducing conditions.

Alloy:

- A general term for a combination of metals or metals with non-metals to enhance specific properties such as strength, corrosion resistance, or heat resistance.

- Includes a wide range of materials such as stainless steel, Inconel, Monel, and Hastelloy.

Key Difference: Hastelloy is a specific brand of alloy, whereas “alloy” is a broader term that encompasses many types of material combinations.

Yes, Hastelloy is classified as a superalloy, also known as a high-performance alloy. Superalloys are designed for excellent mechanical strength, thermal stability, and corrosion resistance at high temperatures. Hastelloy fits this definition due to its ability to perform in extreme chemical environments and under high thermal and mechanical stress, making it widely used in industries like aerospace, chemical processing, and power generation.

Alloy:

- Refers to a material made by combining two or more elements, at least one of which is a metal, to achieve improved properties like strength, corrosion resistance, or conductivity.

- Example: Brass (copper + zinc), Steel (iron + carbon).

Metal Alloy:

- A subset of alloys specifically involving metals as the primary components.

- Example: Stainless steel (iron + chromium + nickel), Bronze (copper + tin).

Key Difference: “Alloy” is a broader term that includes combinations of metals and non-metals, while “metal alloy” focuses solely on mixtures where metals are the primary elements.