Hastelloy Wire / Mesh

Product Grades: Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy X, Hastelloy B-2,

W.Nr. 2.4819, 2.4602, 2.4675, 2.4617, UNS N06022, N10276, N06200, N06002, N10665.

Implementation Standards:

- ASTM B574: Standard specification for nickel alloy rods and wires.

- ASTM B575: Standard specification for nickel alloy mesh and sheets.

Certification: ISO9001:2015.

Applications:

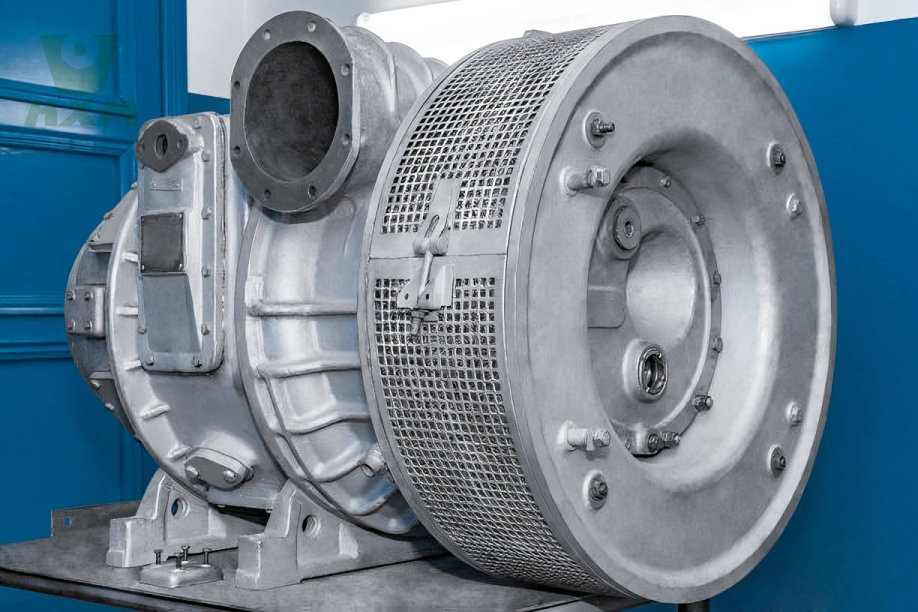

- Chemical Processing: Ideal for filtration and separation systems in harsh environments.

- Pollution Control Systems: Efficient in emission reduction equipment.

- Marine and Aerospace: Suitable for extreme and corrosive conditions.

- Power Generation: Preferred for high-temperature and pressure components.

MOQ: 500 KG.

Payment Methods: T/T, L/C.

Price: Negotiable.

Hastelloy Wire / Mesh Supplier

Huaxiao Alloy specializes in supplying Hastelloy Wire and Mesh of exceptional quality. Our products meet international standards like ASTM B574 and ASTM B575, ensuring superior corrosion resistance and outstanding performance in extreme environments.

As a leading supplier in China, we provide a comprehensive range of Hastelloy Wire and Mesh grades, including C-22, C-276, C-2000, X, and B-2. Manufactured at advanced facilities, our products undergo strict quality checks to ensure compliance with global standards like ISO9001:2015.

We cater to industries such as chemical processing, pollution control, marine, aerospace, and power generation. Customization options are available to meet specific client requirements, including unique dimensions or finishes.

Contact us today for more information or to request a quote for Hastelloy Wire / Mesh.

Specifications for Hastelloy Wire / Mesh

| Category | Diameter Range | Length Range | Standard Specifications |

|---|---|---|---|

| Hastelloy Wire | 0.05 mm – 5 mm | Customizable | ASTM B574, ASME SB574 |

| Hastelloy Mesh | Custom Wire Diameter | Custom Mesh Dimensions | ASTM B575, ASME SB575 |

Standards

- ASTM B574: Standard specification for nickel alloy rods and wires.

- ASTM B575: Standard specification for nickel alloy sheets and mesh.

Additional Specifications

- Forms: Wires, meshes, and custom configurations.

- Surface Finishes: Polished, bright, or pickled finish upon request.

- Applications: Suitable for chemical processing, marine environments, pollution control, and power generation.

- Customization: Wire diameters, mesh sizes, and lengths can be tailored to client needs.

Available Hastelloy Grades

We supply a comprehensive range of Hastelloy wire and mesh grades to meet diverse industrial applications:

- Hastelloy C22 (UNS N06022 / W.Nr. 2.4602): Outstanding resistance to oxidizing and reducing environments, ideal for chemical and pollution control industries.

- Hastelloy C276 (UNS N10276 / W.Nr. 2.4819): Optimal for severe chemical environments, with excellent resistance to chlorine and strong oxidizing agents.

- Hastelloy C2000 (UNS N06200 / W.Nr. 2.4675): Versatile performance in oxidizing and reducing conditions, suitable for a wide range of industries.

- Hastelloy B2 (UNS N10665 / W.Nr. 2.4617): Specialized for hydrochloric acid resistance and aggressive chemical environments.

- Hastelloy B3 (UNS N10675 / W.Nr. 2.4600): Provides superior thermal stability and resists pitting and stress corrosion cracking.

- Hastelloy X (UNS N06002 / W.Nr. 2.4665): Exceptional high-temperature strength and oxidation resistance, widely used in aerospace and industrial heating systems.

- Hastelloy G30 (UNS N06030): Excellent resistance to phosphoric acid and oxidizing acids, with superior performance in fertilizer production.

- Hastelloy G35 (UNS N06035): Optimized for highly oxidizing environments, particularly in wet process phosphoric acid production.

- Hastelloy N (UNS N10003): Engineered for molten salt reactor applications, with outstanding performance at high temperatures.

- Hastelloy C4 (UNS N06455 / W.Nr. 2.4610): High resistance to oxidizing agents and strong acid solutions, particularly nitric acid.

- Hastelloy C22HS (UNS N07022): Enhanced strength and corrosion resistance for demanding environments.

Key Features of Hastelloy Wire / Mesh

- Superior Corrosion Resistance: Outstanding protection against oxidizing, reducing, and mixed chemical environments.

- Exceptional High-Temperature Performance: Retains strength and stability under extreme heat and in aggressive atmospheres.

- Extended Durability: Resists pitting, crevice corrosion, and stress corrosion cracking, ensuring a long service life.

- Chloride Resistance: Designed for optimal performance in marine and chemical industries exposed to chlorides.

- High Tensile Strength: Exceptional mechanical properties for demanding high-stress applications.

Applications of Hastelloy Wire / Mesh

- Chemical Processing: Widely used in filtration, separation, and chemical reaction systems due to its resistance to corrosive chemicals.

- Marine Environments: Suitable for seawater applications and offshore structures, providing excellent resistance to chloride-induced corrosion.

- Pollution Control Systems: Ideal for emission control equipment, including scrubbers, filters, and mist eliminators.

- Aerospace Industry: Utilized in high-temperature and corrosive conditions for critical components.

- Power Generation: Applied in heat exchangers, boilers, and high-temperature components of power plants.

- Pharmaceuticals: Ensures high purity in filtration systems and chemical production processes.

- Water Treatment: Used in desalination plants and wastewater filtration due to its anti-corrosion properties.

Packaging & Delivery

Packaging Options:

- Bundles with plastic wrapping for weather protection.

- Wooden crates or pallets for safe transportation.

- Custom packaging available based on client requirements.

Delivery Time: 10-25 days or faster if stock is available.

Why Choose Huaxiao Alloy?

- Made in China: Trusted supplier of high-quality Hastelloy Wire and Mesh with extensive expertise in the international market.

- Comprehensive Product Range: Offers a full spectrum of Hastelloy grades and customizable sizes to meet diverse industrial needs.

- Uncompromised Quality Control: Products adhere strictly to international standards, including ASTM and ASME, ensuring superior performance and reliability.

- Global Presence: A proven track record of serving clients across Europe, the Americas, the Middle East, and Asia with on-time delivery and excellent support.

- Competitive Pricing: High-performance Hastelloy Wire and Mesh available at cost-effective rates without compromising quality.

Contact us today for detailed information or to request a customized solution for Hastelloy Wire and Mesh tailored to your specific needs!

Get Quote Now for Hastelloy Wire / Mesh

FAQs

The strongest wire mesh is typically made from materials like stainless steel or superalloys such as Hastelloy. These materials offer excellent tensile strength, corrosion resistance, and durability, making them ideal for demanding applications in construction, chemical processing, and marine environments.

Hastelloy C22 and C276 are both nickel-based superalloys, but they differ slightly in composition and performance:

- C22: Offers better resistance to oxidizing agents and a wider range of chemical environments, including ferric and cupric chlorides.

- C276: Provides exceptional resistance to reducing agents, such as hydrochloric acid, and is particularly effective in environments with localized corrosion, such as pitting and crevice corrosion.

Gabion wire mesh is a type of mesh used to create structures like retaining walls, riverbank reinforcements, and erosion control barriers. It is made of heavy-duty galvanized or PVC-coated steel wires, woven into rectangular or hexagonal patterns, and filled with stones or other materials to provide stability and protection.

Coated wire mesh is wire mesh treated with a protective layer, such as PVC, galvanized zinc, or epoxy, to enhance its corrosion resistance, durability, and aesthetic appeal. The coating helps protect the underlying wire from environmental factors like moisture, chemicals, and abrasion.

- Coated Wire: Features a protective layer (e.g., PVC, epoxy, or zinc), which provides enhanced resistance to corrosion, weathering, and wear. It is ideal for outdoor or harsh environments.

- Uncoated Wire: Lacks a protective layer and is more susceptible to rust, corrosion, and mechanical wear. It is usually less expensive but requires more maintenance in corrosive environments.

Some disadvantages of wire mesh include:

- Limited Flexibility: Wire mesh may not conform well to irregular surfaces or shapes.

- Corrosion: Uncoated or poorly coated meshes can corrode in harsh environments.

- Cost: High-quality or specialty wire meshes (e.g., Hastelloy or stainless steel) can be expensive.

- Strength Limitation: Thin wire mesh may lack the structural strength of thicker materials like rebar in heavy-duty applications.

The “best” type of mesh depends on the application:

- Hastelloy or stainless steel mesh: Best for high corrosion resistance in chemical or marine environments.

- Galvanized mesh: Cost-effective and corrosion-resistant for general applications.

- PVC-coated mesh: Suitable for aesthetic and weather-resistant uses.

- Welded steel mesh: Ideal for structural reinforcement in construction.

Wire mesh is not as strong as rebar for heavy-duty structural reinforcement. Rebar provides superior tensile strength and is specifically designed for concrete reinforcement in high-load applications. Wire mesh is more suitable for lighter applications, such as preventing cracking in concrete slabs or fences.