GH3030 Alloy High-temp

GH3030 alloy solid solution strengthened high temperature alloy is the early development of 80Ni – 20Cr solid solution strengthened high temperature alloy, the chemical composition is simple, below 800 ℃ has satisfactory thermal strength and high plasticity, and has a good resistance to oxidation, thermal fatigue, cold stamping and welding process performance.

GH3030 alloy Production Standard

| Alloy | Seamless Pipe and Tube | Welded Pipe and Tube | Plate, Sheet, and Strip | Forging |

|---|---|---|---|---|

| GH3030 | GJB 1952, GJB 3317, GJB 3318 | GJB 2297, GB/T 15062 | GJB 2611, GJB 2612, GJB 3165, GJB 3167 | GJB 3020 |

GH3030 supplier in China——Huaxiao-alloy

GH3030 alloy High-temp

GH3030 alloy data sheet

GH3030 alloy Production Forms

| Product | Condition |

|---|---|

| Sheet | hot or cold rolled, bright/solution annealed, pickled or de-scaled |

| Strip | cold rolled, bright/solution annealed, pickled or de-scaled |

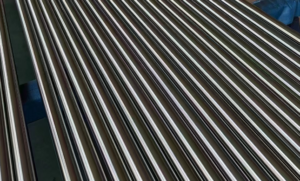

| Pipe | longitudinally welded or seamless, solution annealed, pickled or de-scaled |

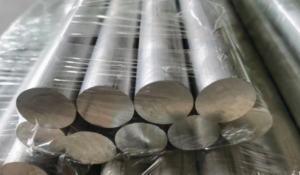

| Bar | hot rolled or forged, solution annealed, pickled or de-scaled |

| Wire | rolled or drawn, solution annealed, pickled or de-scaled |

| Forging | solution annealed, machined on request |

| Welding filler metal | welding bar, wire electrode, coated bar electrode |

Chemical composition of GH3030 alloy(%)

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| C | 0.12 | |

| Cr | 19 | 22 |

| Ni | Remainder | |

| Ti | 0.15 | |

| Fe | 1.5 | |

| Co | 0.5 | |

| Mn | 0.8 | |

| Si | 1 | |

| Mo | 0.5 | 2 |

| Cu | 0.5 | |

| W | 0.08 | |

| P | 0.04 | |

| S | 0.04 | |

| Al | 0.15 |

GH3030 alloy supplier in China——Huaxiao-alloy

Physical properties of GH3030 alloy

| Property | Value |

|---|---|

| Density (g/cm³) | 8.4 |

| Melting Range (°C) | 1374-1420 |

Mechanical properties of GH3030 alloy

| Property | Value |

|---|---|

| Yield Strength Rp0.2 (MPa) | 650 |

| Tensile Strength Rm (N/mm²) | 270 |

| Elongation A5 (%) | 30 |

GH3030 alloy supplier in China——Huaxiao-alloy

Alloys similar to GH3030 alloy

GH3030 is a nickel-chromium-iron alloy known for its strength and corrosion resistance at high temperatures. Here are several alloys that share similar characteristics with GH3030, making them suitable alternatives in various applications:

1. Inconel 600

- Composition: Mainly composed of nickel, chromium, and iron.

- Properties: Exhibits high strength and good corrosion resistance under a wide range of temperatures.

- Applications: Widely used in heat treating furnaces, chemical and food processing, and nuclear engineering.

2. Incoloy 800

- Composition: Nickel, iron, and chromium form the base of this alloy, with significant levels of each to ensure stability and resistance.

- Properties: Known for its strength and resistance to oxidation and carburization at elevated temperatures.

- Applications: Used in super-heater and re-heater tubing, and other high-temperature applications.

3. Hastelloy X

- Composition: A nickel-chromium-iron-molybdenum alloy that includes additional elements for enhanced durability.

- Properties: Offers excellent oxidation resistance and remains structurally stable at high temperatures.

- Applications: Commonly used in gas turbine components and furnace parts.

4. GH3128

- Composition: Similar nickel-chromium-iron base with additional alloying elements for specific property enhancements.

- Properties: This alloy provides good creep resistance at high temperatures.

- Applications: Suitable for aerospace components and other high-temperature industrial applications.

5. GH3039

- Composition: Another variant in the same family as GH3030, with adjustments in the alloy composition to meet specific performance criteria.

- Properties: Known for its high-temperature capability and strength.

- Applications: Often used in aerospace engine parts and high-temperature gas environments.

When considering an alternative to GH3030, it’s important to closely match the mechanical properties and corrosion resistance required for your specific application. Consulting with material scientists or engineers during the selection process can help ensure that the chosen alloy will perform adequately under the intended operational conditions.

Applications of GH3030 alloy

GH3030, a high-performance nickel-based superalloy, is primarily valued for its excellent high-temperature strength and oxidation resistance. Here’s a structured overview of its applications:

1. Aerospace Industry

- Engine Components: GH3030 is utilized in the manufacture of critical engine parts that are exposed to high temperatures and require superior strength and corrosion resistance.

- Turbine Blades: Its ability to withstand high temperatures without losing mechanical integrity makes it ideal for turbine blades in jet engines.

2. Industrial Applications

- Heat Treatment Equipment: GH3030’s high-temperature resistance is perfect for components in industrial furnaces and ovens, where maintaining structural stability at elevated temperatures is crucial.

- Chemical Processing: The alloy is used in reactors and containers within the chemical processing industry due to its excellent resistance to oxidation and corrosive environments.

3. Power Generation

- Boiler Components: GH3030 is suitable for parts in boilers that operate under high heat and pressure, ensuring longevity and reliability.

4. Oil and Gas Industry

- Piping and Valves: In oil and gas exploration and processing, GH3030 is used for piping, valves, and other components that encounter high temperatures and corrosive substances.

GH3030’s robust properties ensure it is a critical material in environments that demand high strength and durability, paired with resistance to heat and corrosion. This makes it an indispensable material for advanced engineering requirements across various critical industries.

FAQs about GH3030 alloy

GH3030 is a high-temperature nickel-based superalloy primarily used for components that require high oxidation resistance and thermal stability. It is commonly used in the aerospace and power generation industries due to its excellent performance in high-temperature environments.

Zircaloy is an alloy made predominantly of zirconium with small amounts of tin, iron, and nickel. It is widely used in the nuclear industry for cladding fuel elements because of its low absorption of neutrons and high corrosion resistance.

Monalite materials are typically high-density calcium silicate boards, which are used for high-temperature insulation and fire protection applications. They are known for their structural strength and thermal stability up to about 1000°C.

SuperQuilt is a multi-layer insulation blanket that consists of a combination of reflective foil, polyethylene terephthalate (PET) wadding, and other insulating materials. It is designed to provide excellent thermal resistance in building applications, helping to improve energy efficiency.

Durovent is a brand of polystyrene foam venting products used in roofing and attic applications. It is designed to promote air circulation and reduce moisture buildup, improving energy efficiency and preventing mold growth.

Metamaterials are not made of a specific material but are rather structured composites, typically consisting of ordinary materials like metals and plastics arranged in periodic or non-periodic structures that manipulate electromagnetic waves and achieve properties not found in nature. They are used in a variety of applications including optics, radar technology, and telecommunications.

Conclusion

GH3030 is a high-temperature nickel-based alloy known for its excellent oxidation resistance, good thermal stability, and strong mechanical properties at elevated temperatures. These characteristics make it particularly suitable for applications in the aerospace industry, gas turbines, and industrial furnaces, where the alloy demonstrates superior resistance to thermal fatigue and oxidation under high heat conditions.

Specialized suppliers like Huaxiao-Alloy provide high-quality GH3030 to ensure industries have reliable materials that perform well in extreme temperature environments. GH3030’s outstanding properties make it a vital material for industries requiring advanced high-temperature alloys to maintain performance and durability in harsh conditions.

How to choose a GH3030 alloy supplier?

Selecting a supplier for GH3030, a specialized nickel-based superalloy, involves careful consideration to ensure quality, reliability, and suitability for specific applications. Here are key steps to help you choose the right GH3030 supplier:

1. Verify Quality Certifications

- Ensure the supplier has appropriate certifications such as ISO 9001 for quality management systems. For aerospace applications, certifications like AS9100 may be necessary.

2. Assess Production Capabilities

- Evaluate the supplier’s production capacity and technology to ensure they can meet your volume needs and technical specifications without compromising quality.

3. Check Material Traceability and Testing

- The supplier should provide full traceability of their materials and robust testing data to verify the material properties such as composition, mechanical properties, and resistance characteristics.

4. Experience and Market Reputation

- Consider suppliers with a proven track record in supplying GH3030. Look for reviews, testimonials, and case studies. Experience in industries that use high-temperature alloys, like aerospace or energy, is particularly valuable.

5. Financial Stability

- Ensure the supplier is financially stable, which is important for long-term supply agreements. Financial health can impact their ability to invest in quality raw materials and maintain consistent supply chains.

6. Customer Service and Technical Support

- Choose a supplier that offers strong customer service and technical support. They should be responsive and capable of providing technical assistance regarding alloy applications.

7. Price and Cost Effectiveness

- While not the only factor, price is significant. Evaluate if the pricing is competitive in the market and reflects the quality of the materials. Consider the total cost of ownership including shipping, handling, and any customization required.

8. Sustainability and Compliance

- If applicable to your industry or corporate policy, consider the supplier’s commitment to environmental sustainability and adherence to regulatory compliance.

9. Request Samples

- If possible, request samples of the GH3030 alloy to assess quality firsthand before committing to a large order.

By systematically evaluating these factors, you can select a GH3030 supplier that not only meets your technical requirements but also aligns with your business’s operational standards and ethical practices. This careful selection process will help ensure a reliable and effective supply chain for your high-temperature alloy needs.