GH3128 Alloy High-temp

GH3128 alloy (GH128) is a nickel-based alloy solid solution strengthened with tungsten and molybdenum and strengthened with boron, cerium and zirconium grain boundaries, with high plasticity, high creep strength and good oxidation resistance and stamping, welding and other properties. Its comprehensive performance is better than GH3044 and GH3536 and other similar nickel-based solid solution alloys.

GH3128 Production Standard

| Product Form | Standards |

|---|---|

| Sheet/Strip | GJB 1952, GJB 3317, GB/T 14995, GB/T 14996 |

| Seamless Tube | GB/T 15062 |

| Welded Tube | GJB 2612 |

| Bar/Wire/Round Disc | GJB 2612, GJB 2617, GJB 3527A |

| Forging/Forged Flange | Q/3B 4088 (Capillary Material) |

GH3128 alloy

GH3128 alloy supplier in China——Huaxiao-alloy

GH3128 data sheet

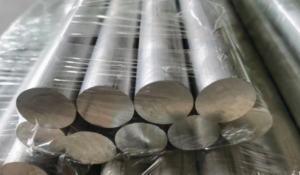

GH3128 Alloy Production Forms

| Product | Condition | Application |

|---|---|---|

| Sheet | Hot or cold rolled, bright/solution annealed, pickled or de-scaled | Gas turbine components, heat exchangers, combustion liners |

| Strip | Cold rolled, bright/solution annealed, pickled or de-scaled | Springs, fasteners, sealing rings |

| Pipe | Longitudinally welded or seamless, solution annealed, pickled or de-scaled | High-temperature piping systems, exhaust manifolds |

| Bar | Hot rolled or forged, solution annealed, pickled or de-scaled | Bolts, shafts, engine components |

| Wire | Rolled or drawn, solution annealed, pickled or de-scaled | Springs, wire mesh, electrical resistance heating elements |

| Forging | Solution annealed, machined on request | Turbine discs, compressor blades |

| Welding filler metal | Welding bar, wire electrode, coated bar electrode | Welding applications in high-temperature environments |

Chemical composition of GH3128 alloy(%)

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 55.0 – 61.0 |

| Chromium (Cr) | 18.0 – 21.0 |

| Iron (Fe) | ≤ 3.0 |

| Molybdenum (Mo) | 2.8 – 3.3 |

| Cobalt (Co) | ≤ 1.0 |

| Titanium (Ti) | 0.35 – 0.75 |

| Aluminum (Al) | 0.15 – 0.50 |

| Manganese (Mn) | ≤ 0.5 |

| Silicon (Si) | ≤ 0.5 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.010 |

| Carbon (C) | ≤ 0.08 |

| Boron (B) | 0.003 – 0.01 |

GH3128 alloy supplier in China——Huaxiao-alloy

Physical properties of GH3128 alloy

| Property | Value |

|---|---|

| Density | 8.1 g/cm³ |

| Melting Range | 1330 – 1380 °C |

| Thermal Conductivity | 11.4 W/m·K (at 20°C) |

| Specific Heat Capacity | 460 J/kg·K (at 20°C) |

| Coefficient of Thermal Expansion | 12.8 × 10⁻⁶ /K (20 – 1000°C) |

| Electrical Resistivity | 1.18 μΩ·m (at 20°C) |

| Young’s Modulus | 206 GPa (at 20°C) |

| Poisson’s Ratio | 0.32 |

Mechanical properties of GH3128

| Property | Value |

|---|---|

| Tensile Strength (σb) | 900 – 1100 MPa |

| Yield Strength (σ0.2) | ≥ 600 MPa |

| Elongation (δ5) | ≥ 20% |

| Reduction of Area (ψ) | ≥ 20% |

| Hardness (HB) | 200 – 240 |

| Creep Rupture Strength (600°C, 1000h) | ≥ 196 MPa |

| Fatigue Strength | 540 MPa (10⁷ cycles, R = -1) |

GH3128 supplier in China——Huaxiao-alloy

Applications of GH3128 Alloy

GH3128 is a nickel-based superalloy known for its excellent high-temperature strength, oxidation resistance, and good fabricability. It is used in various industries where these properties are critical. Below are the main applications of GH3128:

1. Aerospace Industry

- Turbine Components: GH3128 is widely used in the manufacturing of turbine blades, discs, and other critical components in aircraft engines. The alloy’s ability to retain its mechanical properties at elevated temperatures makes it ideal for these applications.

- Combustion Chambers: The alloy is employed in the construction of combustion chambers due to its resistance to high-temperature oxidation and corrosion, ensuring longevity and reliability in harsh environments.

2. Power Generation

- Gas Turbines: GH3128 is utilized in the hot sections of gas turbines, such as vanes, blades, and exhaust systems. Its high creep resistance and thermal stability are crucial for efficient and long-lasting turbine operation.

- Heat Exchangers: The alloy is also used in heat exchangers where high thermal conductivity and resistance to thermal fatigue are required.

3. Chemical and Petrochemical Industry

- Furnace Components: GH3128’s resistance to oxidation and sulfidation at high temperatures makes it suitable for furnace components, such as retorts and trays used in the chemical processing industry.

- Piping Systems: The alloy is used in high-temperature piping systems, particularly in environments that involve corrosive gases or chemicals, ensuring both durability and performance.

4. Automotive Industry

- Exhaust Manifolds: In high-performance automotive applications, GH3128 is used for exhaust manifolds due to its ability to withstand high temperatures and thermal cycling without degradation.

5. Industrial Equipment

- Heat Treatment Equipment: The alloy is used in components such as furnace rolls, belts, and fixtures in heat treatment plants due to its high-temperature strength and resistance to thermal shock.

- Springs and Fasteners: GH3128 is used in the production of high-temperature springs and fasteners where mechanical stability at elevated temperatures is essential.

6. Nuclear Industry

- Reactor Components: GH3128 is employed in nuclear reactors, particularly in components exposed to high temperatures and corrosive environments, due to its excellent combination of strength and corrosion resistance.

Conclusion

GH3128’s exceptional properties, such as high-temperature strength, oxidation resistance, and good fabricability, make it a versatile material suitable for demanding applications across multiple industries. Whether in aerospace, power generation, or chemical processing, GH3128 is relied upon for its durability and performance under extreme conditions.

FAQs about GH3128 Alloy

The toughness of an alloy is determined by its ability to absorb energy and undergo plastic deformation before fracturing. One of the toughest alloys known is Tungsten Heavy Alloy (WHA). Tungsten itself has one of the highest melting points and tensile strengths among metals, and when alloyed with elements like nickel and iron, it forms an extremely tough material. WHAs are used in applications requiring high density and toughness, such as radiation shielding, counterweights, and military applications.

Ferrosilicon is an alloy of iron and silicon, typically containing 15-90% silicon. It is primarily used as a deoxidizer and alloying agent in steelmaking. By adding ferrosilicon to molten steel, oxygen is removed, which improves the steel’s quality. Additionally, ferrosilicon is used in the production of silicon steel for transformer cores and electromotors, and in the manufacturing of cast iron, as it promotes the formation of graphite.

The strongest fictional alloy widely recognized in popular culture is Adamantium, from the Marvel Comics universe. Adamantium is an indestructible metal alloy famously bonded to Wolverine’s skeleton. It is characterized by its exceptional durability, near-unbreakable nature, and ability to withstand extreme forces and temperatures.

Devarda’s alloy is an alloy composed of aluminum (44-46%), copper (49-51%), and zinc (4-6%). It is primarily used in analytical chemistry for the quantitative determination of nitrates. When Devarda’s alloy is added to an alkaline solution containing nitrate ions, it reduces the nitrates to ammonia, which can then be measured to determine the concentration of nitrates.

One of the most expensive alloys in the world is Platinum-Iridium Alloy. This alloy is highly valuable due to its rarity and specialized applications, particularly in high-precision instruments and the production of the international prototype of the kilogram, which was made from a 90% platinum and 10% iridium alloy. The combination of platinum’s high value and iridium’s extreme resistance to corrosion and high melting point makes this alloy extraordinarily expensive.

While no alloy is harder than diamond, which is the hardest known natural material, some synthetic materials like Aggregated Diamond Nanorods (ADNR) and wurtzite boron nitride are claimed to be slightly harder than diamond under certain conditions. However, in the context of alloys, there isn’t one that surpasses diamond in hardness. Diamond’s hardness is a result of its crystal structure, which gives it unparalleled resistance to scratching.

Conclusion

GH3128 is a high-performance nickel-based alloy renowned for its outstanding oxidation resistance, excellent high-temperature strength, and durability under extreme thermal environments. These attributes make GH3128 an optimal choice for applications in the aerospace, power generation, and chemical processing industries, where it effectively withstands oxidation and thermal fatigue.

Specialized suppliers like Huaxiao-Alloy offer top-grade GH3128 alloy to ensure industries have access to reliable materials that meet the stringent demands of high-temperature applications. The unique properties of GH3128 make it an essential solution for advanced engineering challenges in critical sectors.

How to choose a GH3128 supplier?

When selecting a supplier for GH3128 alloy, it’s essential to consider several critical factors to ensure you receive high-quality material that meets your specific needs. Here’s a structured approach to choosing the right GH3128 supplier:

1. Supplier Reputation and Experience

- Industry Expertise: Choose a supplier with extensive experience in producing or distributing GH3128 alloy. Suppliers with a solid track record in the industry are more likely to provide consistent, high-quality materials.

- Customer Reviews and Testimonials: Research the supplier’s reputation through customer reviews, testimonials, and case studies. Positive feedback from other clients, particularly in industries similar to yours, is a good indicator of reliability.

2. Product Quality and Certification

- Material Certification: Ensure the supplier provides GH3128 alloy with all necessary certifications, such as ISO 9001 or AS9100. These certifications indicate that the supplier adheres to strict quality management standards.

- Compliance with Specifications: Verify that the supplier’s GH3128 alloy complies with relevant industry standards and specifications. This may include ASTM, AMS, or other applicable standards.

- Third-Party Testing: Look for suppliers who offer third-party testing and verification of their materials. This adds an extra layer of assurance regarding the alloy’s quality and composition.

3. Technical Support and Expertise

- Technical Assistance: Choose a supplier that offers technical support and guidance in selecting the right GH3128 alloy grade and specifications for your application. This support is crucial, especially if your project has unique or demanding requirements.

- Customization and Flexibility: Assess the supplier’s ability to customize the alloy’s properties or dimensions to suit your specific needs. A supplier who can offer flexible solutions will be more valuable in specialized applications.

4. Supply Chain Reliability

- Consistent Supply: Ensure the supplier has a stable and reliable supply chain to avoid delays in delivery. This is particularly important for industries that require just-in-time inventory.

- Lead Times: Evaluate the supplier’s lead times and their ability to meet your project timelines. A supplier with a responsive and efficient supply chain can significantly reduce downtime.

5. Pricing and Value

- Competitive Pricing: While price should not be the only deciding factor, it’s essential to choose a supplier that offers competitive pricing without compromising on quality.

- Total Cost of Ownership: Consider the overall value the supplier provides, including factors like material quality, reliability, and customer support. A slightly higher upfront cost may be justified by lower risks and better long-term performance.

6. After-Sales Service

- Ongoing Support: Select a supplier that provides excellent after-sales service, including support for material issues, returns, or any necessary follow-up.

- Long-Term Partnership: Consider whether the supplier is interested in building a long-term partnership. A reliable partner can be invaluable for future projects requiring GH3128 or other specialized alloys.

7. Sustainability and Ethics

- Sustainable Practices: If sustainability is a priority, choose a supplier that follows environmentally friendly practices in their production and sourcing processes.

- Ethical Sourcing: Ensure the supplier adheres to ethical sourcing and labor practices, particularly if your project has social responsibility requirements.

By carefully evaluating these factors, you can select a GH3128 supplier that not only meets your technical requirements but also supports your overall business goals.