GH4145 Alloy High-temp

GH4145 alloy is mainly γ “[Ni3 (Al, Ti, Nb)] phase aging strengthened nickel-based high-temperature alloys, in the 980 ℃ has a good corrosion and oxidation resistance, 800 ℃ has a higher strength, 540 ℃ has a better resistance to relaxation performance, but also has a good molding properties and welding performance.

GH4145 Production Standard

| Production Standard | Description |

|---|---|

| GB/T 14992-2005 | Superalloy standard for GH series alloys. |

| ASTM B637 | Standard specification for precipitation-hardened nickel alloy bar, rod, and wire. |

| AMS 5662 | Specification for Nickel Alloy, Bars, Forgings, and Rings, 50Ni – 19Cr – 3.0Ti – 1.4Al – 5.0(Nb + Ta), 1775°F (968°C) Solution Heat Treated, Precipitation Hardened. |

| AMS 5663 | Specification for Nickel Alloy, Bars, Forgings, and Rings, 50Ni – 19Cr – 3.0Ti – 1.4Al – 5.0(Nb + Ta), 1775°F (968°C) Solution Heat Treated, Precipitation Hardened (Alternate to AMS 5662). |

| UNS N07718 | Unified Numbering System designation for GH4145/Inconel 718. |

| ISO 15156/NACE MR0175 | Standards for materials in H2S-containing environments in oil and gas production. |

GH4145 alloy

GH4145 alloy supplier in China——Huaxiao-alloy

GH4145 alloy data sheet

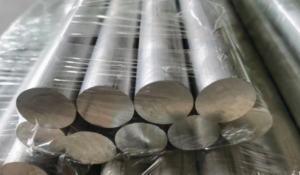

GH4145 Alloy Production Forms

| Production Form | Description |

|---|---|

| Seamless Pipe and Tube | GH4145 is produced in seamless pipe and tube forms for high-pressure and high-temperature applications. |

| Welded Pipe and Tube | Welded GH4145 pipes and tubes are used where cost-effectiveness and custom lengths are essential. |

| Plate, Sheet, and Strip | GH4145 plates, sheets, and strips are available for use in structural components and heat-resistant applications. |

| Bar and Rod | GH4145 is provided in bar and rod forms, often used in aerospace and marine components requiring high strength. |

| Wire | GH4145 wire is produced for applications like fasteners, springs, and welding electrodes. |

| Forging | Forgings from GH4145 alloy are utilized in components that demand high mechanical strength and corrosion resistance. |

| Fittings | GH4145 fittings are manufactured for joining pipes and components in high-temperature environments. |

| Flanges | GH4145 flanges are produced for connecting pipes, valves, and other equipment in high-pressure systems. |

Chemical composition of GH4145 alloy(%)

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 50.0 – 55.0 |

| Chromium (Cr) | 17.0 – 21.0 |

| Iron (Fe) | Bal. (remainder) |

| Niobium (Nb) + Tantalum (Ta) | 4.75 – 5.50 |

| Molybdenum (Mo) | 2.80 – 3.30 |

| Titanium (Ti) | 0.65 – 1.15 |

| Aluminum (Al) | 0.20 – 0.80 |

| Cobalt (Co) | 1.00 max |

| Copper (Cu) | 0.30 max |

| Silicon (Si) | 0.35 max |

| Manganese (Mn) | 0.35 max |

| Carbon (C) | 0.08 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

| Boron (B) | 0.006 max |

GH4145 supplier in China——Huaxiao-alloy

Physical properties of GH4145 alloy

| Property | Value |

|---|---|

| Density | 8.19 g/cm³ (8190 kg/m³) |

| Melting Range | 1260 – 1340 °C |

| Thermal Conductivity | 11.4 W/m·K at 20 °C |

| Specific Heat Capacity | 435 J/kg·K at 20 °C |

| Electrical Resistivity | 1.25 µΩ·m at 20 °C |

| Young’s Modulus | 205 GPa at 20 °C |

| Poisson’s Ratio | 0.29 at 20 °C |

| Coefficient of Thermal Expansion | 13.0 µm/m·K (20 – 100 °C) |

| Hardness | 330 – 370 HB |

| Tensile Strength | 965 MPa (minimum) |

| Yield Strength (0.2% Offset) | 550 MPa (minimum) |

| Elongation | 20 – 25% (minimum) |

Mechanical properties of GH4145 Alloy

| Property | Value |

|---|---|

| Tensile Strength | 965 MPa (minimum) |

| Yield Strength (0.2% Offset) | 550 MPa (minimum) |

| Elongation at Break | 20 – 25% (minimum) |

| Reduction of Area | 30% (minimum) |

| Hardness | 330 – 370 HB |

| Creep Strength (at 650°C, 1000h) | 700 MPa |

| Fatigue Strength | 620 MPa (at 10^7 cycles, room temperature) |

| Impact Toughness | 120 J (minimum, at room temperature) |

| Modulus of Elasticity | 205 GPa (at room temperature) |

| Shear Strength | 550 MPa |

GH4145 alloy supplier in China——Huaxiao-alloy

Applications of GH4145 alloy

GH4145 alloy, also known as a type of precipitation-hardening stainless steel, is widely used in various applications due to its superior mechanical properties and resistance to oxidation and corrosion. Here’s a structured overview of its applications:

1. Aerospace Industry

- Components: Used for turbine blades, compressor discs, and other high-stress components in jet engines.

- Reasons: Its high strength-to-weight ratio and ability to withstand high temperatures make it ideal for aerospace applications.

2. Automotive Industry

- Components: Utilized in the manufacturing of high-performance engine parts such as crankshafts and camshafts.

- Reasons: GH4145’s strength and durability under high stress and temperature conditions enhance the performance and longevity of automotive components.

3. Oil and Gas Industry

- Components: Applied in the production of high-pressure valves, pump shafts, and drilling tools.

- Reasons: Its resistance to corrosion and wear, combined with its high tensile strength, makes it suitable for harsh environments encountered in oil and gas extraction.

4. Power Generation

- Components: Employed in turbine blades and other high-temperature components in power plants.

- Reasons: GH4145’s ability to maintain mechanical properties at elevated temperatures is crucial for efficient power generation.

5. Marine Industry

- Components: Used in marine engine parts and other components exposed to corrosive seawater.

- Reasons: Its corrosion resistance ensures durability and reliability in marine environments.

6. Chemical Processing

- Components: Applied in chemical reactors and other equipment that requires resistance to corrosive chemicals.

- Reasons: GH4145’s resistance to various chemicals and high-temperature stability make it suitable for chemical processing applications.

7. Structural Components

- Components: Utilized in high-load structural components such as bridges and buildings.

- Reasons: The alloy’s high strength and toughness are advantageous in structural applications where load-bearing capacity is critical.

Summary

GH4145 alloy is valued for its high strength, excellent toughness, and resistance to high temperatures and corrosion. These properties make it a versatile material suitable for demanding applications across various industries, including aerospace, automotive, oil and gas, power generation, marine, chemical processing, and structural engineering.

FAQs about GH4145

One of the toughest alloys in the world is Maraging Steel, known for its exceptional strength and toughness achieved through martensitic transformation and aging treatment. This alloy is commonly used in aerospace, rocket components, and nuclear facilities. Another extremely tough alloy is Inconel 718, which maintains excellent mechanical properties under high temperatures and harsh environments, making it suitable for aerospace engines and gas turbines.

The strongest fictional alloy is often considered to be Adamantium, which appears in the “X-Men” series and is nearly indestructible. Another famous fictional alloy is Vibranium from the Marvel Universe, known for its ability to absorb and store energy, making it one of the hardest and strongest materials.

Alloy 410 is a type of martensitic stainless steel primarily composed of iron and chromium. It offers good corrosion resistance and high strength. 410 stainless steel can be heat-treated to enhance its hardness and wear resistance, making it suitable for manufacturing tools, valves, and pump shafts that require high strength and wear resistance.

Nickel alloys and Hastelloy are not the same. Hastelloy is a type of nickel-based alloy known for its excellent corrosion resistance, especially in extreme environments like acidic and high-temperature conditions. Nickel alloys encompass a broader range, including Hastelloy, Inconel, Monel, and others, each tailored for specific applications based on different alloying elements and processing methods.

Rhenium alloy is considered one of the rarest alloys in the world. Rhenium is a rare metal mainly used to create high-temperature superalloys, such as Rhenium-Tungsten alloys, known for their stability under extreme high temperatures. These alloys are widely used in jet engines and aerospace industries. Due to the rarity and high value of rhenium, its alloys are also extremely precious.

While diamond is the hardest known natural material, some man-made alloys and materials exhibit similar or even greater hardness under specific conditions. For example, Cubic Boron Nitride (cBN) is an ultra-hard material second only to diamond, and it remains more stable than diamond at high temperatures. Recently, artificially created ultra-hard materials, such as super-hard carbon nanotube structures, have also shown hardness exceeding that of diamonds in certain situations.

Conclusion

GH4145 is a high-performance alloy renowned for its exceptional strength, toughness, and resistance to high temperatures and corrosion. Its superior mechanical properties make it highly suitable for demanding applications across diverse industries, including aerospace, automotive, oil and gas, power generation, marine, and chemical processing.

Specialized suppliers like Huaxiao-Alloy offer high-quality GH4145 to meet the rigorous demands of these industries, ensuring reliability and performance in critical applications. GH4145’s unique combination of strength, durability, and resistance to extreme conditions establishes it as a crucial material for advanced engineering and industrial requirements.