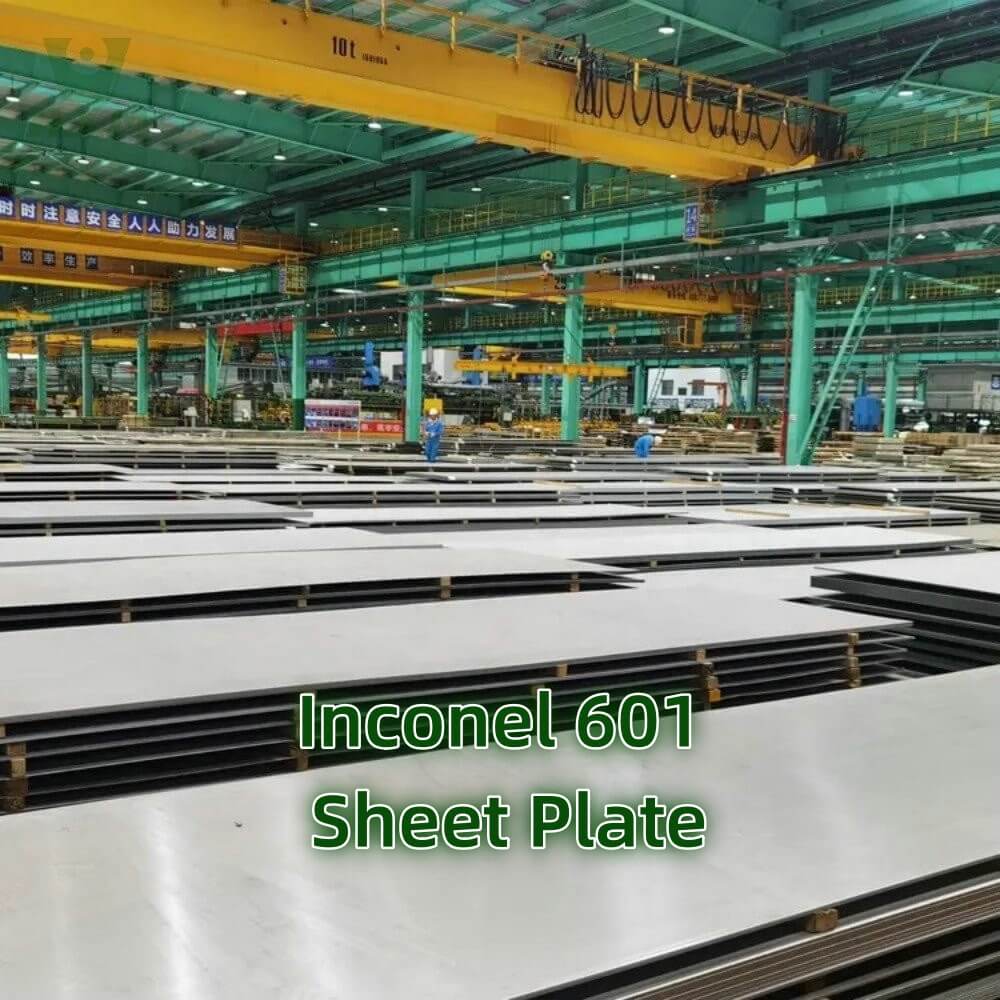

Inconel 601 Sheet / Plate / Coil

Grades and International Standards

International Designations

- UNS: N06601

- Werkstoff Nr.: 2.4851

- Other Names: Alloy 601, NCF 601 (Japan), NS 3102 (China)

Production Standards

As a certified Inconel 601 manufacturer, Huaxiao-Alloy complies with globally recognized specifications:

- ASTM B168: Standard for nickel-chromium-iron alloy plates, sheets, and strips.

- AMS 5715: Aerospace Material Specification for high-temperature applications.

- EN 10095: European standard for heat-resistant stainless steels and nickel alloys.

- GB/T 15007: Chinese national standard for corrosion-resistant alloys.

Certifications

- ISO 9001:2015 Quality Management

- AS9100D Aerospace Certification

- NACE MR0175 (Sour Service Compliance)

Product Specifications of Inconel 601 Sheet / Plate / Coil

Huaxiao-Alloy, as a premier Inconel 601 supplier, offers customizable dimensions and surface finishes:

| Form | Thickness Range (mm) | Width Range (mm) | Length/Coil Diameter | Surface Finish | Tolerance |

|---|---|---|---|---|---|

| Sheet | 0.5–6 | 100–2000 | Custom (Max 6000 mm) | Cold-rolled, Polished (Ra ≤0.8µm) | ±0.05 mm (Thickness) |

| Plate | 6–100 | 500–2500 | Custom (Max 12000 mm) | Hot-rolled, Pickled, Machined | ±1% (Width/Length) |

| Coil | 0.5–4 | 300–1500 | ID 508–610 mm, OD ≤2000 mm | Bright Annealed, Protective Film | ±0.02 mm (Thickness Uniformity) |

Notes:

- Custom cutting (laser, waterjet, plasma) available for rapid prototyping.

- Non-standard sizes require a 25% deposit with 30-day lead time.

Mechanical Properties of Inconel 601 Sheet / Plate / Coil

Room Temperature Performance

| Property | Value | Testing Standard |

|---|---|---|

| Tensile Strength | ≥655 MPa | ASTM E8/E8M |

| Yield Strength (0.2% Offset) | ≥240 MPa | ASTM E8/E8M |

| Elongation (% in 50 mm) | ≥30% | ASTM E8/E8M |

| Hardness (Brinell) | ≤150 HB | ASTM E10 |

| Impact Toughness (Charpy) | ≥100 J (20°C) | ASTM E23 |

Elevated Temperature Performance

| Temperature | Tensile Strength | Creep Rupture Strength (1000h) | Oxidation Rate (mg/cm²·h) |

|---|---|---|---|

| 600°C | 520 MPa | 120 MPa | <0.1 (Air) |

| 1000°C | 180 MPa | 35 MPa | <0.5 (Cyclic Oxidation) |

| 1200°C | 90 MPa | – | <1.0 (Continuous Service) |

Key Advantages:

- Retains 85% of room-temperature strength at 1000°C.

- Exceptional thermal fatigue resistance due to low expansion coefficient (14.2 µm/m°C at 20–1000°C).

Chemical Composition of Inconel 601 Sheet / Plate / Coil

Nominal Composition (wt%)

| Element | Ni | Cr | Fe | Al | C | Mn | Si | Cu | S |

|---|---|---|---|---|---|---|---|---|---|

| Content | 58.0 | 23.0 | 14.0 | 1.4 | 0.05 | 0.50 | 0.50 | 0.50 | 0.003 |

Material Science Insights:

- Nickel (Ni): Forms the matrix for superior ductility and corrosion resistance.

- Chromium (Cr): Enhances oxidation resistance through Cr₂O₃ layer formation.

- Aluminum (Al): Synergizes with Cr to improve scale adhesion at extreme temperatures.

- Low Carbon (C): Minimizes carbide precipitation, ensuring weldability.

Trace Element Control:

- Sulfur (S): Restricted to <5 ppm to prevent hot cracking.

- Phosphorus (P): <0.02% to maintain grain boundary integrity.

Global Grade Equivalents of Inconel 601 Sheet / Plate / Coil

| Country/Region | Standard | Grade | Comparability |

|---|---|---|---|

| USA | ASTM B168 | UNS N06601 | Direct Equivalent |

| Europe | EN 10095 | 2.4851 | Identical Chemistry |

| Japan | JIS G4902 | NCF 601 | Mechanical Parity |

| China | GB/T 15007 | NS 3102 | Fully Interchangeable |

| Russia | GOST 5632 | ХН60Ю | Similar High-Temp Performance |

Unique Product Characteristics of Inconel 601 Sheet / Plate / Coil

1. Extreme Temperature Stability

- Continuous service up to 1250°C (2282°F) in oxidizing atmospheres.

- Resists scaling in sulfur-containing environments (e.g., petrochemical crackers).

2. Corrosion Resistance

- Oxidation: <0.1 mm/year thickness loss at 1100°C.

- Carburization/Nitriding: Performs in hydrocarbon processing with <5% carburization depth after 1000h at 950°C.

- Chloride Stress Corrosion Cracking (CSCC): Immune in marine environments (ASTM G36 tested).

3. Fabrication Advantages

- Weldability: Excellent with TIG (ERNiCrFe-11) or MIG (Inconel 112 filler).

- Formability: 25% cold work achievable without annealing.

4. Cost Efficiency

- 30% longer service life than Inconel 600 in furnace applications.

- Reduces downtime in chemical processing plants by resisting ash corrosion.

Industry Applications of Inconel 601 Sheet / Plate / Coil

Aerospace

- Client: European Turbine Manufacturer

- Component: Combustion chamber liners

- Result: 15% weight reduction vs. Haynes 230, with 20,000-hour service life.

Energy

- Client: Middle East Oil Refinery

- Component: Pyrolysis reactor tubes

- Result: Operated at 1150°C for 5 years without replacement.

Industrial Manufacturing

- Client: Japanese Automotive Supplier

- Component: Continuous annealing furnace rolls

- Result: Eliminated roll warping, saving $500k/year in maintenance.

Huaxiao-Alloy’s Value Addition:

- Provided stress-relieved Inconel 601 plates pre-machined to client CAD files.

- Delivered 15 tons of bright-annealed coils within 10 days for emergency plant maintenance.

Why Partner with Huaxiao-Alloy?

1. Technical Leadership

- Proprietary vacuum induction melting (VIM) ensures <10 ppm oxygen purity.

- 25+ metallurgists on staff for alloy optimization.

2. Quality Assurance

- 100% ultrasonic testing for plates >10 mm thickness.

- Batch-specific MTRs include:

- Melt chemistry

- Heat treatment records (annealed at 1150°C ±10°C)

- Mechanical test results

3. Global Logistics Network

- Stock hubs in Rotterdam (Europe), Houston (USA), and Shanghai (Asia).

- DDP (Delivered Duty Paid) terms available for hassle-free import.

4. Sustainability Commitment

- 98% material utilization rate through precision cutting.

- Recyclable scrap buyback program.

Get Quote Now

A1: While Inconel 625 excels in aqueous corrosion, Huaxiao-Alloy’s Inconel 601 offers 200°C higher temperature capability and 40% lower cost for furnace applications.

A2: Yes, we’re certified for offshore oil/gas projects requiring NORSOK compliance.

A3: Coils: Wooden crates with VCI paper; Sheets/Plates: Waterproof wrapping on steel pallets.

A4: Yes, Huaxiao-Alloy offers certified AWS welding workshops for bulk orders.

A5: 500 kg for standard grades; trial orders of 100 kg accepted for R&D projects.