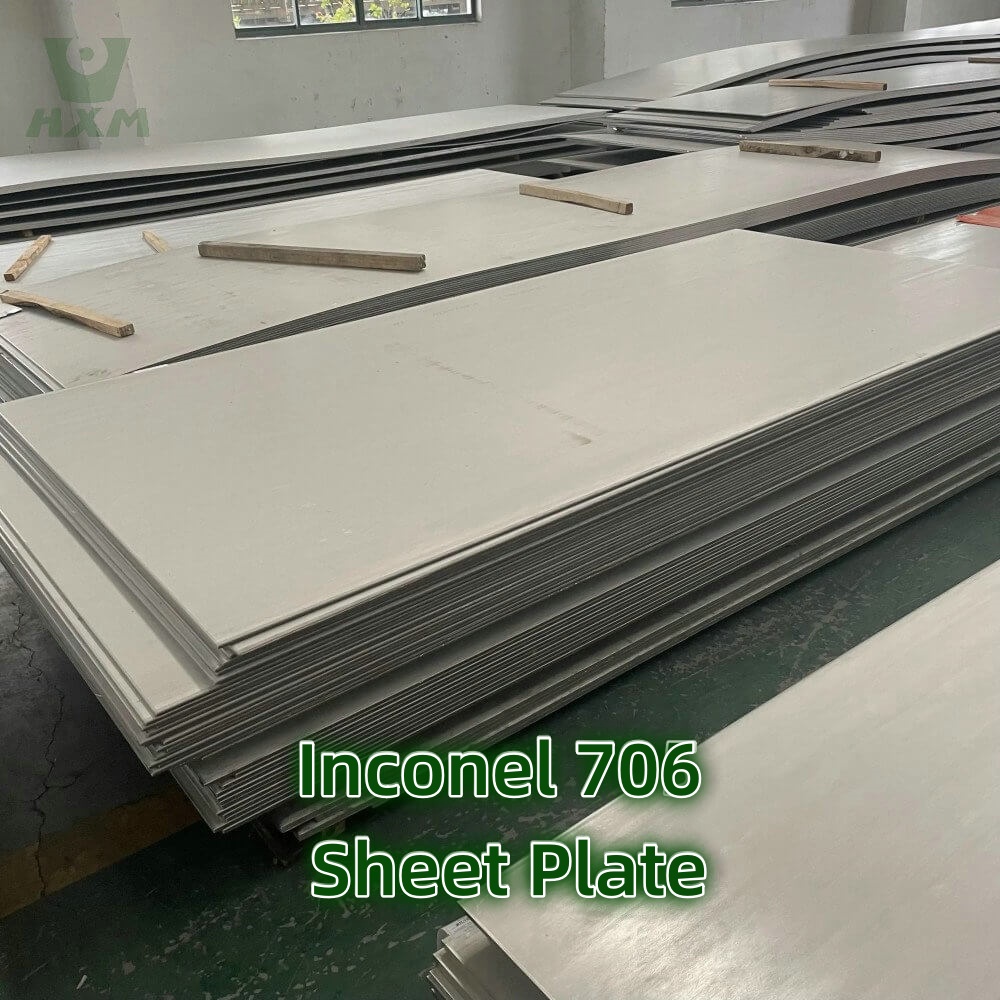

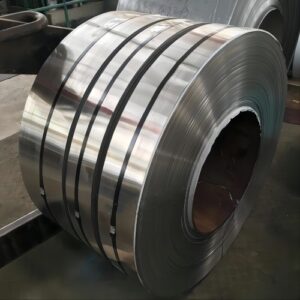

Inconel 706 Sheet / Plate / Coil

Inconel 706 is a nickel-iron-chromium superalloy strengthened by niobium and molybdenum additions, designed for high-temperature applications requiring exceptional strength, creep resistance, and weldability. As a premier Inconel 706 Sheet/Plate/Coil manufacturer, Huaxiao-Alloy supplies this alloy under the following designations:

- UNS N07706

- EN 2.4669

- W. Nr. 2.4669

Huaxiao-Alloy’s Inconel 706 products comply with stringent international standards for aerospace, power generation, and industrial applications:

- ASTM B637 (Bar/Coil)

- ASTM B670 (Plate/Sheet)

- ASME SB637

- AMS 5716

- DIN 17752

Our Inconel 706 Plate supplier team adheres to certifications including ISO 9001, AS9100, and NADCAP, ensuring aerospace-grade quality and full traceability.

Available Product Specifications

| Product Form | Thickness (mm) | Width (mm) | Length (mm) | Surface Finish |

|---|---|---|---|---|

| Sheet | 0.5–25 | 800–2500 | 2000–6000 | Cold-rolled, Annealed |

| Plate | 5–120 | 1500–3500 | 3000–12000 | Hot-rolled, Pickled |

| Coil | 0.5–6 | 400–1500 | Custom | Annealed, Polished |

Custom dimensions and tolerances are available upon request from this Inconel 706 Coil manufacturer.

Mechanical Properties

Inconel 706 delivers outstanding performance in extreme environments:

- Tensile Strength: 1100–1300 MPa

- Yield Strength (0.2% Offset): 750–950 MPa

- Elongation: 15–25%

- Hardness: 280–350 HB

- Density: 8.22 g/cm³

These properties make Huaxiao-Alloy’s Inconel 706 Sheet ideal for gas turbine discs, shafts, and high-stress aerospace components.

Chemical Composition

| Element | Ni | Cr | Fe | Nb+Ta | Mo | Ti | Al | C | Mn |

|---|---|---|---|---|---|---|---|---|---|

| **% Content** | 39–44 | 14–17 | Bal. | 2.5–3.3 | 2.5–3.3 | 1.5–2.0 | 0.2–0.6 | ≤0.08 | ≤0.35 |

The niobium and molybdenum additions enhance precipitation hardening, a hallmark of Huaxiao-Alloy’s Inconel 706 Plate.

Cross-National Designations

| Country | Standard | Equivalent Grade |

|---|---|---|

| USA | ASTM/ASME | UNS N07706 |

| Europe | EN | 2.4669 |

| Japan | JIS | NCF 706 |

| Germany | DIN | W. Nr. 2.4669 |

| China | GB | GH4706 |

As a global Inconel 706 Sheet supplier, we ensure compliance with regional specifications for seamless integration into your projects.

Key Characteristics

- High-Temperature Stability: Retains strength up to 700°C (1292°F) under continuous load.

- Creep Resistance: Withstands prolonged stress at elevated temperatures.

- Weldability: Compatible with TIG, MIG, and electron beam welding.

- Fatigue Resistance: Performs under cyclic loading in harsh environments.

- Age-Hardenable: Achieves peak strength through heat treatment.

These attributes position Huaxiao-Alloy’s Inconel 706 Coil as a top choice for advanced aerospace and energy systems.

Applications

- Aerospace: Turbine discs, compressor blades, engine mounts.

- Power Generation: Gas turbine rotors, steam turbine components.

- Oil & Gas: Downhole tools, wellhead equipment, subsea connectors.

- Industrial Heating: Furnace fixtures, heat treatment trays.

- Nuclear Energy: Reactor core fasteners, control rod mechanisms.

Trust Huaxiao-Alloy, a leading Inconel 706 Plate manufacturer, for materials that withstand extreme operational challenges.

Why Choose Huaxiao-Alloy?

- Technical Expertise: 25+ years of experience in high-performance alloy production.

- End-to-End Solutions: Precision machining, heat treatment, and non-destructive testing (NDT).

- Certified Quality: Full traceability with Mill Test Certificates (MTCs) and 3.1/3.2 inspection reports.

- Global Logistics: Efficient shipping to 60+ countries via air, sea, or land.

- Sustainability: Eco-conscious manufacturing aligned with ISO 14001 standards.

Our Inconel 706 Sheet supplier team provides 24/7 technical support, including material selection and application engineering.

Get Quote Now

Get Quote Now

Solution annealing at 980–1020°C (1796–1868°F) followed by aging at 720°C (1328°F) optimizes strength and corrosion resistance.

Yes, our Inconel 706 products meet NACE MR0175/ISO 15156 standards for hydrogen sulfide (H₂S) environments.

Yes, but post-forming heat treatment is recommended to restore mechanical properties.

Inconel 706 offers similar strength but improved weldability and lower cost, making it ideal for large structural components.

Standard stock items ship within 2–3 weeks; custom orders require 6–8 weeks for processing and quality assurance.