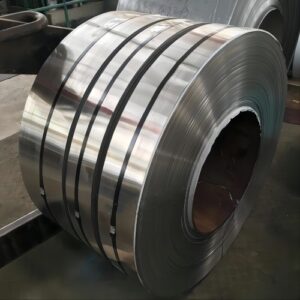

Inconel Strip / Precision Strip

Product Grades: Inconel 625, Inconel 718, Inconel X-750, Inconel 600 (UNS N06625, N07718, N07750, N06600)

Implementation Standards: ASTM B443, ASTM B670, ASTM B168; ASME SB443, ASME SB670, ASME SB168

Certification: ISO 9001:2015

Features:

- Corrosion Resistance: Superior performance in both oxidizing and reducing environments.

- High Strength: Maintains robustness under high temperatures and pressures.

- Durability: Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

Applications: Perfect for use in aerospace, power generation, marine, and chemical processing industries requiring high precision and reliability.

MOQ: 500 kg

Payment Methods: T/T, L/C

Price: Negotiable

Inconel Strip / Precision Strip Supplier

Inconel Alloy Strips, Inconel Foil Sheets, ASME SB168 Inconel High Precision Plates, Inconel Slitting Coils, and precision rolled strip supplier in China.

Inconel Cold Rolled Strips, ASTM B443 Inconel Precision Shim Sheets, Inconel Flat Sheets, Inconel Alloy Plates Exporter, Inconel Strip Dealer Worldwide.

Huaxiao Alloy, a precision rolled strip supplier and exporter based in China, specializes in offering a comprehensive range of Inconel Alloy Strips, Sheets, and Plates to customers across the globe. Renowned for their remarkable oxidation and corrosion resistance, our Inconel products excel in the most demanding environments. These strips and sheets are crafted in cutting-edge facilities, undergoing stringent quality assessments to comply with top international standards, such as ASTM, ASME, and DIN.

Our product lineup includes Inconel Alloy Strips and Plates in a variety of grades, such as Inconel 625, 718, X-750, and 600. These are available in multiple thicknesses, widths, and finishes, ensuring they are perfectly suited for high-performance applications in aerospace, chemical processing, power generation, and marine industries.

We also provide tailored solutions and customization services to meet specific industrial requirements, helping our clients achieve optimal performance and efficiency in their projects.

Specifications for Inconel Strip / Precision Strip

| Category | Thickness Range | Width Range | Length Range | Standard Specifications |

|---|---|---|---|---|

| Inconel Precision Strips | 0.1 mm – 6 mm | 20 mm – 500 mm | 500 mm – 3000 mm | ASTM B443, ASME SB443 |

| Inconel Fine Strips | 0.1 mm – 1 mm | 10 mm – 200 mm | 200 mm – 1500 mm | ASTM B443, ASME SB443 |

- Standards: ASTM B443, ASME SB443

- Sizes:

- Width: 20mm, 50mm, 100mm, 200mm, 500mm

- Length: 500mm, 1000mm, 2000mm, 3000mm, or as per customer requirements

- Thickness Range: 0.1mm to 6mm

- Forms: Strips, Precision Rolls

- Surface Finishes: 2B, BA, No.4, Mirror, HL (Hairline)

- Hardness Levels: Soft, Half Hard, Quarter Hard, Full Hard

Available Inconel Grades

We supply the following grades of Inconel alloy strips and precision strips:

- Inconel 600 (UNS N06600 / W.Nr. 2.4816): Offers high strength and good corrosion resistance under a wide range of temperatures and conditions.

- Inconel 601 (UNS N06601 / W.Nr. 2.4851): Known for its resistance to high-temperature oxidation, with excellent durability in cyclic heating conditions.

- Inconel 625 (UNS N06625 / W.Nr. 2.4856): Provides outstanding resistance to corrosion and oxidation, making it ideal for severe service environments.

- Inconel 718 (UNS N07718 / W.Nr. 2.4668): Combines corrosion resistance and high strength with outstanding weldability, including resistance to post-weld cracking.

- Inconel X-750 (UNS N07750 / W.Nr. 2.4669): Features excellent resistance to relaxing and good corrosion resistance under high-stress and temperatures.

- Inconel 725 (UNS N07725): Offers high strength and toughness along with resistance to aqueous corrosion and oxidation.

Each of these grades is carefully engineered to meet the highest performance standards required by the most challenging industrial environments. These materials are suitable for a wide range of applications in industries such as aerospace, marine engineering, and chemical processing due to their unique properties.

Key Features of Inconel Strip / Precision Strip

1. Unmatched Corrosion Resistance: Inconel strips are renowned for their ability to withstand extreme environments, making them an ideal choice for industries dealing with corrosive substances. Whether you operate in the chemical processing sector, oil and gas production, or marine environments, our Inconel strips provide assurance against corrosion-related failures, thereby reducing maintenance costs and extending the service life of your projects.

2. Exceptional High-Temperature Stability: For applications requiring performance at high temperatures, Inconel strips deliver exceptional thermal stability without losing their strength. This makes them perfect for use in aerospace, automotive, and power generation industries where operational conditions can reach extreme levels.

3. Superior Strength and Durability: Engineered for resilience, Inconel strips offer high tensile strength and toughness over a broad temperature range. This property ensures that our products are not only durable but also versatile enough to be used in heavy-duty applications such as aerospace structures, gas turbine components, and nuclear reactor cores.

4. Excellent Fabricability: Despite their strength, Inconel strips are remarkably workable. They can be easily fabricated into complex shapes and sizes, tailored to precise specifications, which is essential for manufacturing sectors requiring high precision and customization.

5. Cost-Effectiveness Over Time: Investing in Inconel strips means reduced repair and replacement costs. Their durable nature translates into longer lifecycles for parts and assemblies, which in turn decreases the total cost of ownership.

6. Ready for Challenging Applications: Whether it’s facing the deep-sea salinity or the acidic environments of chemical reactors, Inconel strips are up to the task. Their robustness in facing harsh conditions means you can push the boundaries of what’s possible in your operations.

Empower Your Projects with Inconel Strip / Precision Strip

Leverage the advanced properties of our Inconel strips to enhance the efficiency and reliability of your applications. Contact us today to discover how we can tailor our solutions to meet your specific needs, or click below to learn more about the diverse applications and custom solutions we offer.

Get More Information Contact Us

Applications of Inconel Strip / Precision Strip

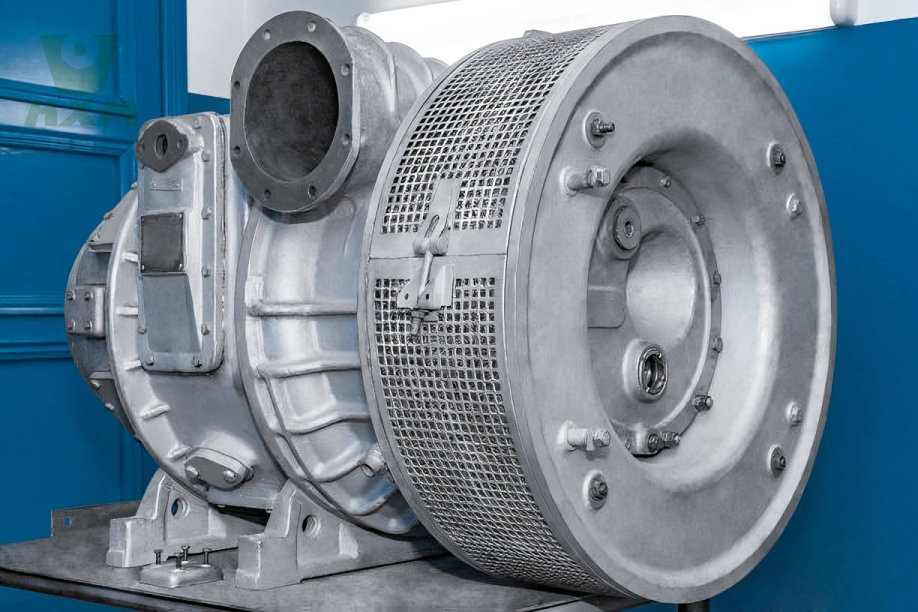

1. Aerospace: Inconel strips are widely used in the aerospace industry for components that must withstand extreme heat and pressure, such as turbine blades, exhaust systems, and heat shields. Their resistance to oxidation and corrosion at high temperatures ensures reliability and longevity in harsh flight conditions.

2. Automotive: In high-performance automotive applications, Inconel strips are used in exhaust systems and turbocharger rotors. They handle the high temperatures and corrosive environments often experienced in performance engines, contributing to enhanced durability and efficiency.

3. Oil and Gas: The oil and gas industry utilizes Inconel strips in applications such as downhole and subsea equipment, where materials must resist the corrosive effects of sour gas and other harsh substances. Inconel’s corrosion resistance makes it ideal for piping, valves, and separators in these settings.

4. Chemical Processing: Inconel strips are essential in the chemical processing industry due to their ability to maintain structural integrity under corrosive conditions involving acids, alkalis, and other chemicals. They are commonly used in reactors, heat exchangers, and storage tanks.

5. Power Generation: In power plants, Inconel strips are used in boiler seals, gas turbine components, and nuclear engineering. Their resistance to high-temperature oxidation is crucial for maintaining performance in the extreme heat of energy production environments.

6. Marine: The marine industry uses Inconel strips in shipbuilding and repair, specifically in parts exposed to seawater, which can be highly corrosive. Their use in propeller blades, submarine parts, and exhaust systems helps ensure longevity and reliability.

7. Electronics: In the electronics industry, Inconel precision strips are used in the manufacture of high-temperature furnace components and semiconductor processing equipment, where materials must withstand thermal cycling and react minimally with other substances.

8. Medical: For medical applications, Inconel strips are used in surgical instruments, implants, and equipment that require sterilization at high temperatures. Their bio-compatibility and ability to endure the autoclaving process without degradation make them suitable for critical medical environments.

Packaging & Delivery

Packaging Options:

- Bundles with plastic wrapping for weather protection.

- Wooden crates or pallets for safe transportation.

- Custom packaging available based on client requirements.

Delivery Time: 10-25 days or faster if stock is available.

Why Choose Huaxiao Alloy?

1. Specialized Expertise: Deep knowledge in crafting Inconel strips, ensuring each product meets stringent performance standards.

2. Precision Manufacturing: We utilize cutting-edge technology to produce strips with precise dimensions and superior finish, tailored to exact customer specifications.

3. Rigorous Quality Assurance: Each strip undergoes thorough testing under ISO 9001:2015 standards to guarantee top quality and consistency.

4. Global Distribution: Our efficient supply chain ensures prompt delivery of Inconel strips anywhere in the world, supporting just-in-time manufacturing needs.

5. Customer-Centric Service: Huaxiao Alloy is dedicated to providing detailed support and flexible solutions to accommodate specific industry applications and requirements.

6. Commitment to Innovation: Continuous improvement in our processes and products to lead the market in high-performance materials.

7. Sustainability Focus: We are committed to sustainable practices in manufacturing, reducing environmental impact while maintaining product excellence.

8. Value-Oriented Pricing: Competitive pricing for Inconel strips, ensuring customers receive excellent value without compromising on quality.

Get Quote Now for Inconel Strip / Precision Strip

FAQs

Yes, alloy 625 and Inconel 625 refer to the same material. Inconel 625 is a specific brand name used by Special Metals Corporation for a nickel-chromium alloy known generically as alloy 625. This alloy is known for its high strength, outstanding corrosion resistance, and excellent fabricability.

The Surface Feet per Minute (SFM) for turning Inconel 625 typically ranges from 40 to 60 SFM. However, the exact speed can vary based on the tooling material, machining setup, cooling conditions, and the specific machining operation being performed. It is important to note that Inconel 625 is a hard-to-machine material, requiring robust tooling and often slower speeds to manage work hardening and heat generation.

Inconel 625 is covered under various ASTM standards depending on the form of the material. For instance:

- ASTM B443 for plate, sheet, and strip.

- ASTM B446 for bar and forging.

- ASTM B564 for forgings and rings.

- ASTM B705 and B704 for welded pipe. These standards specify requirements for chemical composition, mechanical properties, and other critical aspects of Inconel 625.

Inconel 625 is known primarily for its corrosion resistance and is highly resistant to chloride environments and oxidative conditions. It is non-magnetic, has excellent fatigue strength, and is durable in lower temperature ranges.

Inconel 718, on the other hand, is noted for its incredibly high yield, tensile, and creep-rupture properties at high temperatures up to about 1300°F (704°C). It has excellent weldability compared to the Inconel 625 and is frequently used in applications that require high strength at elevated temperatures.

The main differences lie in their chemical composition and mechanical properties, making them suitable for different applications based on environmental conditions and mechanical demands.

In ASME standards, Inconel 625 is often referenced for its applications in pressure vessels and boilers, especially in high-temperature environments. It is covered under various ASME specifications like:

- ASME SB-443 for plates, sheets, and strips.

- ASME SB-446 for bars and forgings.

- ASME SB-444 and SB-829 for seamless pipes and tubes. These specifications govern the use of Inconel 625 in components exposed to extreme environments, leveraging its resistance to high temperatures and corrosion.

ASTM D575 is a standard specification for rubber properties in compression. It is not related to Inconel or metals but specifies test methods for determining the compression-deflection characteristics of rubber compounds. It includes two methods: Method A for softer rubbers and Method B for harder rubber materials. This standard is important for applications involving rubber cushions, mounts, and similar products to assess their compression characteristics under load.