Inconel Sheet Plate Supplier

Product grades: Inconel 600, Inconel 625, Inconel 718, N07718, W.Nr. 2.4668, NiCr19Fe19Nb5Mo3, NA 51, NC19FeNb

Implementation standards: ASTM B168, ASTM B443, ASTM B670, ASTM B906

Certification: ISO9001:2015

Features: Exceptional creep rupture strength, exceeding 140 MPa at 700°C, ensuring outstanding long-term stability in high-temperature environments. High corrosion resistance, superior resistance to oxidation, pitting, and crevice corrosion. Excellent mechanical properties, maintaining strength and toughness at both cryogenic and elevated temperatures. Good fabricability, suitable for welding, forming, and machining.

Product usage: Aerospace, chemical, marine, and power generation industries.

MOQ: 500KG

Payment method: T/T, LC

Price: To negotiate

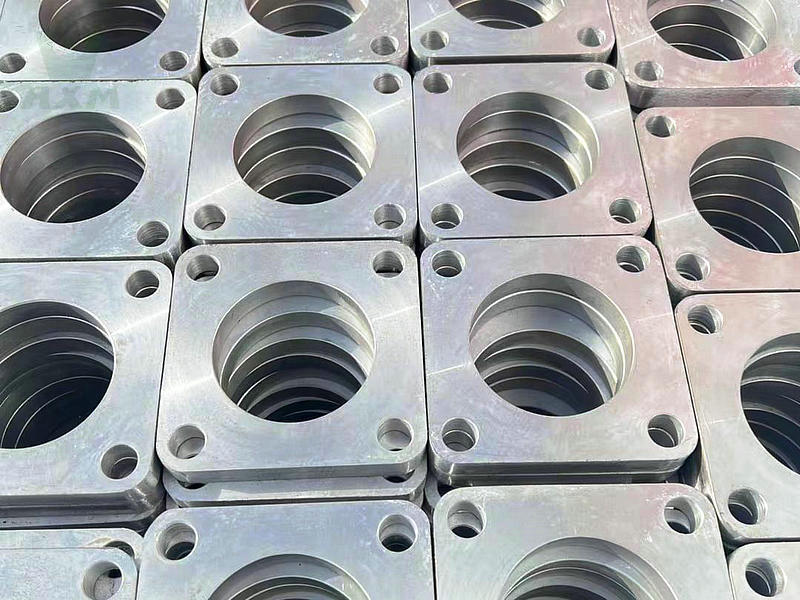

Inconel sheet is a high-performance nickel-chromium alloy known for its exceptional resistance to oxidation and corrosion. It maintains its mechanical properties at elevated temperatures, making it crucial for aerospace, chemical processing, and marine applications. This material is frequently used in heat exchangers, gas turbines, and reactor cores due to its high tensile strength, durability, and ability to perform reliably in extreme conditions.

Dimensions of Inconel sheet Plate Stock in Huaxiao Alloy

| Specification | Details |

|---|---|

| Thickness Range | 0.1 mm to 100 mm |

| Width Range | 600 mm to 2500 mm |

| Length Range | 1000 mm to 6000 mm |

| Standard | ASTM B168, ASTM B443, ASTM B906 |

| Grade | Inconel 600, 601, 625, 718, X750 |

| Surface Finish | No.1, 2B, BA, No.4, HL |

| Tolerance | As per ASTM, ASME standards |

| Form | Sheet, Plate, Coil |

Different grades of Inconel Alloy

Mechanical Properties of Inconel sheet Plate

| Inconel Sheet Plate | Tensile Strength | Yield Strength | Elongation | Hardness | Operating Temperature Range |

|---|---|---|---|---|---|

| Inconel 600 sheet plate | 690 – 930 MPa | 310 – 415 MPa | 30 – 50% | Rb 80-95 | Up to 1000°C |

| Inconel 601 sheet plate | 655 – 750 MPa | 240 – 310 MPa | 30 – 45% | Rb 75-90 | Up to 1200°C |

| Inconel 625 sheet plate | 827 – 1034 MPa | 414 – 758 MPa | 30 – 60% | Rc 30-40 | Up to 982°C |

| Inconel 718 sheet plate | 1030 – 1400 MPa | 550 – 1240 MPa | 12 – 25% | Rc 30-45 | Up to 704°C |

| Inconel X750 sheet plate | 965 – 1100 MPa | 690 – 1034 MPa | 15 – 25% | Rc 25-40 | Up to 982°C |

Inconel 706 Sheet / Plate / Coil

Huaxiao-Alloy, a trusted Inconel 706 sheet manufacturer, delivers ASTM/ASME-certified sheets, plates, and coils with unmatched high-temperature strength and weldability for aerospace, power generation, and oil & gas industries.

Inconel 718 Sheet / Plate / Coil

Huaxiao-Alloy, a trusted Inconel 718 sheet manufacturer, delivers ASTM/ASME-certified sheets, plates, and coils with unmatched high-temperature strength and corrosion resistance for aerospace, oil & gas, and energy industries.

Inconel 722 Sheet / Plate / Coil

Huaxiao-Alloy, a trusted Inconel 722 sheet manufacturer, delivers ASTM/ASME-certified sheets, plates, and coils with unmatched high-temperature strength and oxidation resistance for aerospace, power generation, and oil & gas industries.

Inconel 725 Sheet / Plate / Coil

Huaxiao-Alloy, a trusted Inconel 725 sheet manufacturer, delivers ASTM/ASME-certified sheets, plates, and coils with unmatched corrosion resistance and high strength for oil & gas, marine, and chemical industries.

Inconel X-750 Sheet / Plate / Coil

Huaxiao-Alloy, a trusted Inconel X-750 sheet manufacturer, delivers ASTM/ASME-certified sheets, plates, and coils with unmatched strength and oxidation resistance for aerospace, nuclear, and industrial applications.

Inconel 751 Sheet / Plate / Coil

Huaxiao-Alloy, a trusted Inconel 751 sheet manufacturer, delivers ASTM/ASME-certified sheets, plates, and coils with unmatched high-temperature strength for aerospace, energy, and automotive industries.

Advantages of each Inconel sheet Plate grade

Inconel 600 Sheet Plate

- Excellent Oxidation Resistance: Provides superior resistance to oxidation and scaling at high temperatures, up to 1000°C, making it ideal for moderate high-temperature applications.

- Corrosion Resistance: Outstanding resistance to a wide range of corrosive environments, including chlorides and sulfur compounds.

- High-Temperature Stability: Maintains mechanical properties and structural integrity at elevated temperatures, making it more versatile for general high-temperature use.

- Versatility: Suitable for various applications such as heat exchangers, furnace components, and chemical processing equipment. Difference: Compared to other grades, it offers a balanced combination of high-temperature strength and corrosion resistance.

Inconel 601 Sheet Plate

- Superior Oxidation Resistance: Outstanding resistance to oxidation at temperatures up to 1200°C, making it ideal for the most extreme thermal environments.

- Enhanced Durability: Resists spalling, even under cyclic thermal conditions.

- Corrosion Resistance: Excellent resistance to aqueous corrosion and high-temperature corrosion.

- Ease of Fabrication: Can be readily welded and formed using standard processes. Difference: Its ability to withstand the highest temperatures among the grades makes it unique for extreme thermal applications.

Inconel 625 Sheet Plate

- High Strength: Exceptional tensile and yield strength, even at elevated temperatures, up to 982°C.

- Corrosion Resistance: Excellent resistance to pitting, crevice corrosion, and stress-corrosion cracking in chloride environments.

- Fatigue Resistance: Superior fatigue and thermal-fatigue resistance, making it suitable for aerospace and marine applications.

- Versatility: Used in applications ranging from chemical processing to marine engineering and aerospace components. Difference: Offers the highest corrosion resistance and fatigue resistance, especially in chloride environments, setting it apart from other grades.

Inconel 718 Sheet Plate

- High Strength: Extremely high tensile and yield strength, maintained up to 704°C, due to precipitation hardening.

- Creep Resistance: Excellent resistance to creep and stress-rupture at high temperatures.

- Corrosion Resistance: Good resistance to oxidation and corrosion in various environments.

- Manufacturing Ease: Can be easily fabricated and welded. Difference: Its precipitation hardening gives it the highest strength and creep resistance among the grades, particularly suited for high-stress components.

Inconel X750 Sheet Plate

- High Strength and Stability: Maintains high strength and stability over a wide temperature range, up to 982°C.

- Creep Resistance: Excellent resistance to creep and stress-rupture.

- Corrosion Resistance: Good resistance to oxidation and corrosion in high-temperature environments.

- Versatility: Commonly used in gas turbines, rocket engines, and nuclear reactors. Difference: Provides a balance of high strength, stability, and creep resistance, specifically for extreme, high-stress environments, distinguishing it from other grades.

These differences highlight the specific advantages of each Inconel sheet plate grade, ensuring optimal performance and reliability in their respective applications.

Applications of Inconel Sheet Plate

1. Aerospace Industry

Jet Engines and Turbines:

- Inconel 718 Sheet Plate: Used extensively in jet engines and gas turbines for turbine blades, seals, and combustion chamber parts due to its high mechanical strength and creep resistance at high temperatures.

Spacecraft:

- Inconel X750 Sheet Plate: Utilized in rocket engines and other spacecraft components that require excellent performance in extreme temperatures and corrosive environments.

2. Chemical Processing

Heat Exchangers and Reactors:

- Inconel 625 Sheet Plate: Widely used in heat exchangers and reactor vessels within the chemical processing industry for its superior resistance to a wide range of corrosive chemicals, including acids and alkalis.

Piping Systems:

- Inconel 600 Sheet Plate: Suitable for piping systems in harsh chemical environments due to its excellent oxidation and corrosion resistance, ensuring longevity and reliability.

3. Power Generation

Nuclear Reactors:

- Inconel 600 Sheet Plate: Used in steam generator tubing and other components within nuclear reactors for its structural stability and resistance to oxidation and carburization at high temperatures.

Superheater and Reheater Tubes:

- Inconel 600 and Inconel 625 Sheet Plate: Employed in superheater and reheater tubes in fossil fuel power plants, enduring high temperatures and corrosive flue gases.

4. Marine Engineering

Offshore Oil and Gas Extraction:

- Inconel 625 Sheet Plate: Extensively used in offshore platforms and undersea pipelines due to its outstanding resistance to seawater corrosion and high mechanical strength, essential for subsea systems, risers, and flexible pipe connections.

Shipbuilding:

- Inconel 625 Sheet Plate: Its durability and corrosion resistance make it suitable for critical ship components exposed to harsh marine environments.

5. Automotive Industry

Exhaust Systems:

- Inconel 625 Sheet Plate: Used in high-performance and racing car exhaust systems for its ability to withstand high temperatures and corrosive exhaust gases, ensuring improved performance and durability.

Turbochargers:

- Inconel X750 Sheet Plate: Helps maintain efficiency and performance under extreme conditions in turbocharger components.

6. Environmental Control

Pollution Control Equipment:

- Inconel 600 and Inconel 625 Sheet Plate: Utilized in equipment designed to control and reduce environmental pollution, such as scrubbers and heat exchangers in waste treatment facilities, due to their resistance to high-temperature corrosive gases and chemicals.

Desalination Plants:

- Inconel 625 and Inconel 718 Sheet Plate: Crucial in desalination plants for their resistance to saltwater corrosion and high-pressure environments, ensuring efficient and reliable freshwater production.

7. Medical Industry

Medical Devices:

- Inconel 625 Sheet Plate: The biocompatibility, corrosion resistance, and strength of Inconel alloys make them suitable for certain medical devices and surgical instruments that require high reliability and performance under bodily conditions.

Conclusion

Inconel sheet plates are essential across various industries due to their exceptional properties, including high-temperature strength, corrosion resistance, and structural stability. Their applications span critical sectors like aerospace, chemical processing, power generation, marine engineering, automotive, environmental control, and even medical devices. The widespread use of Inconel sheet plates in these areas underscores their significance in advancing technology and ensuring safety and efficiency in extreme and demanding conditions.

Inconel is a family of nickel-chromium-based superalloys known for their exceptional resistance to oxidation, corrosion, and high temperatures. These alloys maintain their strength and stability at temperatures where most metals would degrade. Common grades include Inconel 600, 625, 718, and X750, each tailored for specific high-performance applications.

Yes, Inconel is generally stronger than many types of steel, especially at elevated temperatures. Inconel alloys maintain their mechanical strength and resistance to thermal creep deformation far better than most steels. This makes Inconel ideal for high-temperature and high-stress environments where steel would weaken and fail.

Inconel is a superalloy primarily composed of nickel and chromium. It belongs to a category of materials known as high-performance alloys, which are engineered to withstand extreme conditions, including high temperatures, corrosion, and oxidation. Inconel alloys also contain other elements such as molybdenum, iron, cobalt, and niobium, which enhance their specific properties.

Inconel is used in a variety of applications that demand high strength and resistance to extreme environments:

- Aerospace: Jet engines, turbine blades, and spacecraft components.

- Chemical Processing: Heat exchangers, reactors, and piping systems.

- Power Generation: Nuclear reactors, superheater and reheater tubes.

- Marine Engineering: Offshore oil and gas extraction, shipbuilding.

- Automotive: High-performance exhaust systems and turbochargers.

- Environmental Control: Pollution control equipment, desalination plants.

- Medical: Certain medical devices and surgical instruments.

Inconel is expensive due to several factors:

- Material Composition: The primary elements, nickel and chromium, are costly, and additional alloying elements like molybdenum and niobium further increase the cost.

- Manufacturing Complexity: Inconel requires specialized manufacturing processes, including advanced melting, casting, and machining techniques, which are more complex and expensive than those for common metals.

- Performance Characteristics: Its exceptional properties, such as high-temperature strength, corrosion resistance, and durability, justify the higher cost for critical applications.

Inconel and titanium each have strengths in different areas:

- High-Temperature Performance: Inconel is stronger and more stable at high temperatures, making it superior for applications involving extreme heat.

- Weight: Titanium is much lighter than Inconel, which is advantageous in aerospace and automotive applications where weight savings are crucial.

- Corrosion Resistance: Both materials offer excellent corrosion resistance, but Inconel is often preferred in highly corrosive environments and at higher temperatures.

- Strength-to-Weight Ratio: Titanium has a better strength-to-weight ratio, making it suitable for applications where both strength and lightness are required.