Line equipment

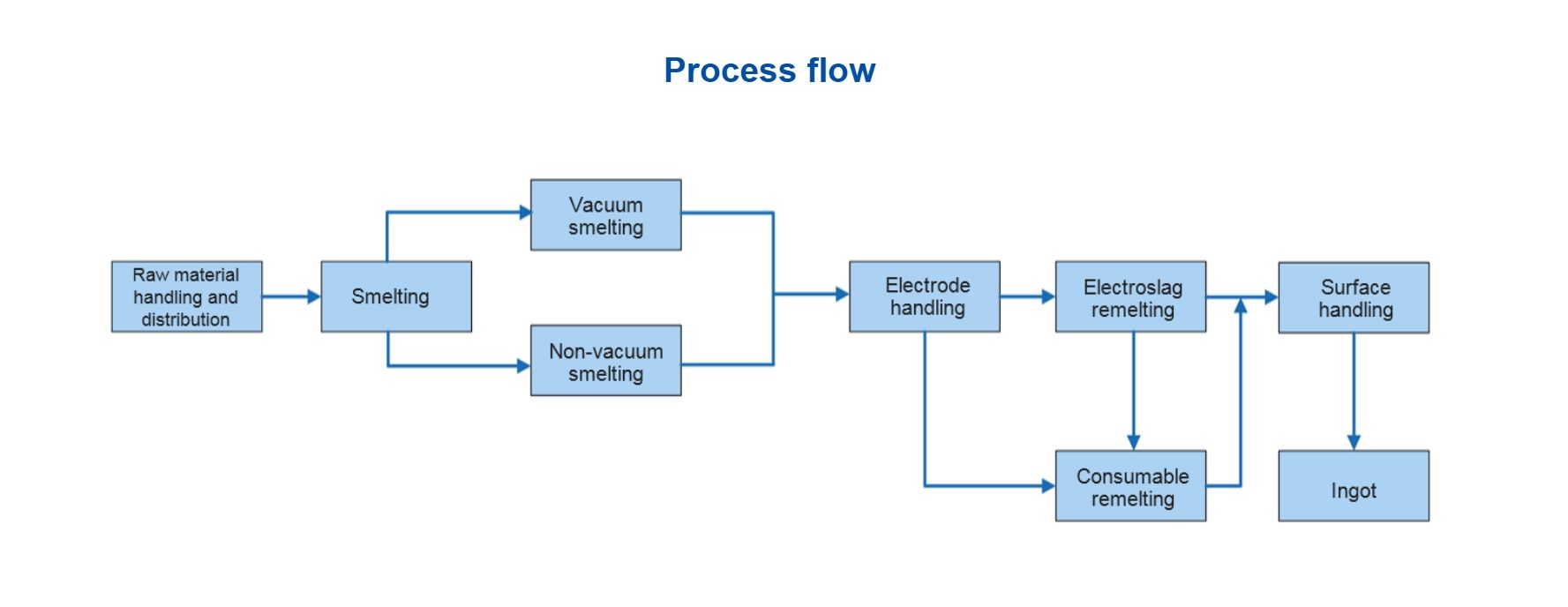

Ultra-Pure Special Smelting

We specialize in providing ultra-pure, high-performance alloys tailored for high-end equipment manufacturing. Our advanced facilities include over ten specialized smelting units, such as an 8,000 kg vacuum induction melting furnace, a 6,000 kg protective atmosphere electroslag remelting furnace, and a 3,000 kg vacuum arc remelting furnace.

Our comprehensive smelting capabilities are built on various advanced techniques, including:

- Vacuum Induction Melting (VIM)

- Primary Vacuum Induction Melting + Secondary Electroslag Remelting (ESR)

- Primary Vacuum Induction Melting + Secondary Vacuum Arc Remelting (VAR)

- Primary Vacuum Induction Melting + Secondary Electroslag Remelting + Tertiary Vacuum Arc Remelting

These capabilities enable us to achieve complete ultra-pure special smelting technology. We can produce electrode ingots ranging from Φ80 to 560 mm, electroslag ingots from Φ125 to 660 mm, and consumable ingots from Φ250 to 508 mm.

Create cutting-edge products in the aviation industry and provide power for the world.

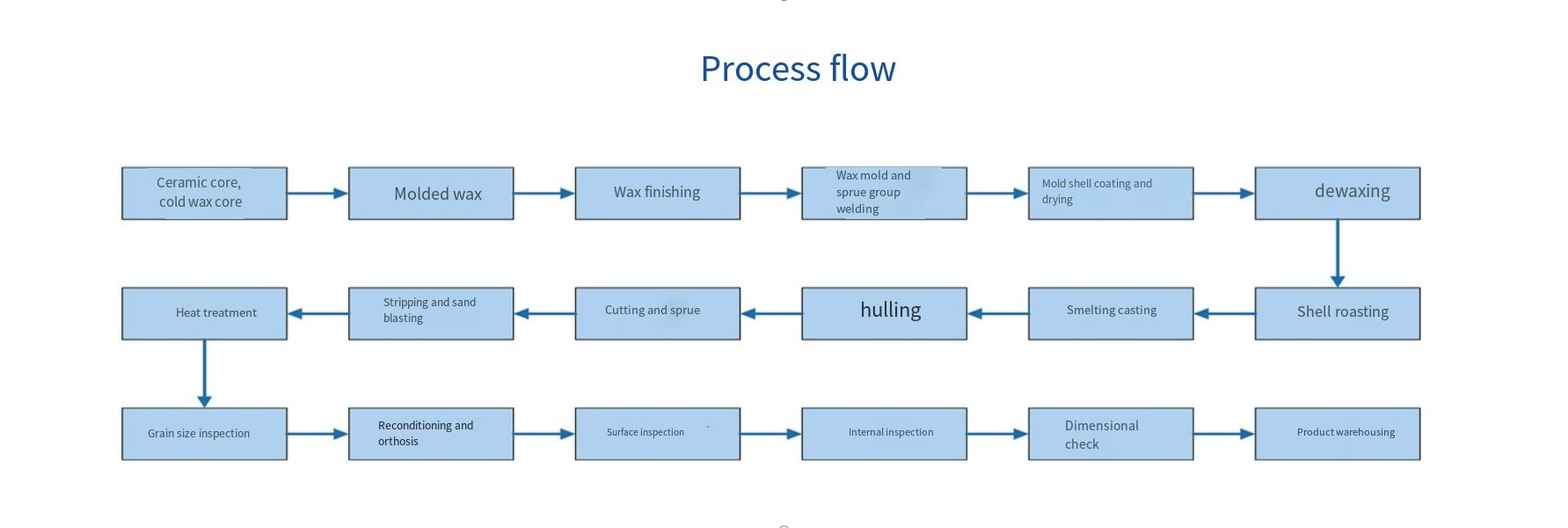

Advanced Equipment: ToLand Alloy is equipped with state-of-the-art investment casting machinery, including:

- Vacuum induction melting precision casting furnaces

- Wax injectors

- Automated robotic and conveyor investing systems

- Vacuum heat treatment furnaces

Advanced Processes: We utilize cutting-edge investment casting techniques, including:

- Gravity casting

- Wax segmentation and assembly

- Specialized gating and runner designs

- Hot sizing techniques

Comprehensive System: Our fully integrated process includes:

- Mold design

- Precision wax assembly

- Gating system design

- High-strength mold shell preparation

- Casting

- Post-processing

- Inspection

Production Capabilities: ToLand Alloy can mass-produce precision castings with:

- Casting weights up to 650 kg

- Maximum diameters up to 1,500 mm

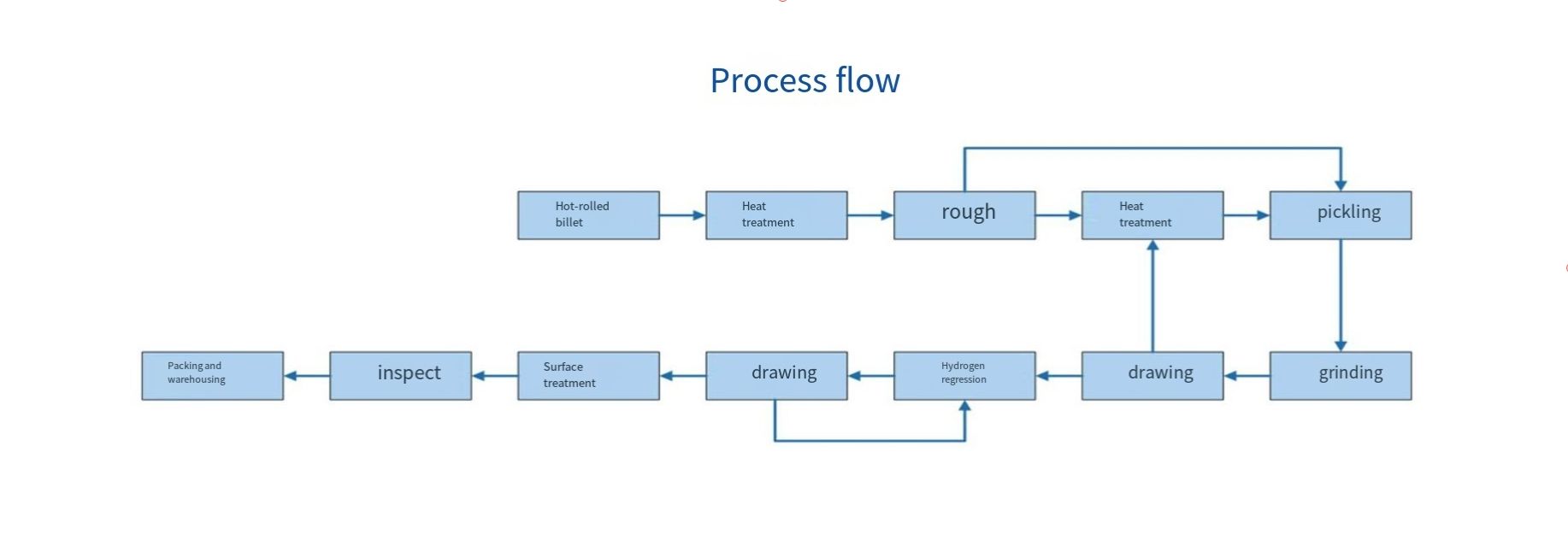

Hot Forging and Hot Rolling, Thoroughly Tempered

Delivering high-performance polished bars for high-end equipment manufacturing.

ToLand Alloy is equipped with over 30 advanced processing units, including 1T-6T free forging hammers, hot rolling heating furnaces, electric heat treatment furnaces, and precision finishing machines for polishing bright materials.

Our capabilities span a full range of processing technologies, including:

- Hot Forging

- Hot Rolling

- Hot Forging + Hot Rolling

- Hot Forging + Cold Drawing

- Hot Rolling + Cold Drawing

- Hot Forging + Hot Rolling + Cold Drawing

Additionally, we offer comprehensive surface treatment processes such as:

- Straightening

- Turning

- Peeling

- Grinding

- Polishing

ToLand Alloy is capable of producing:

- Forged bars with diameters ranging from Φ40 to 300 mm

- Rolled bars with diameters from Φ8 to 120 mm

- Cold-drawn bars with diameters from Φ4 to 50 mm

- Hot-rolled wire rods with diameters from Φ6 to 16 mm

- Plates, strips, and various other profiles

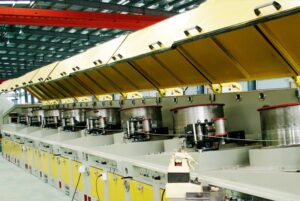

Refined Manufacturing

Supplying specialized wire materials for the shipping, energy, and electronics industries.

ToLand Alloy is equipped with over 20 advanced wire drawing machines, including:

- Continuous wire drawing machines

- Protective atmosphere annealing furnaces

- High-speed water tank wire drawing machines

- Vacuum electric pit furnaces

We specialize in the production of:

- High-temperature alloys

- Precision alloys

- High-resistance alloys

- Welding wire materials

- Other specialized alloy wires

ToLand Alloy offers a range of wire products, including:

- Precision wires with diameters from Φ0.2 to 1 mm

- Round wires with diameters from Φ1 to 15 mm

High-Precision Professional Tube Manufacturing

Delivering high-precision seamless tubing for aerospace and high-end equipment manufacturers.

ToLand Alloy is equipped with over 30 advanced tube manufacturing machines, including:

- High-speed LG cold rolling mills

- LD series precision rolling mills

- Vacuum heat treatment furnaces

- Protective atmosphere heat treatment furnaces

- Ultrasonic cleaning devices

By combining traditional multi-pass cold processing with cutting-edge techniques such as ultrasonic cleaning and vacuum heat treatment, ToLand Alloy has independently developed specialized seamless tube manufacturing technology tailored for aerospace applications.

ToLand Alloy offers seamless tubes in the following specifications:

- Outer Diameter (OD): 4-110 mm

- Thickness (T): 0.5-5 mm

These tubes are available in both stainless steel and high-temperature alloy materials.