Monel metal, a nickel-copper alloy, has been a cornerstone in the world of metallurgy due to its unique combination of properties. This alloy, with its primary components being nickel and copper, along with minor additions of iron and manganese, offers excellent mechanical strength and corrosion resistance, making it an ideal choice for various applications.

What is Monel metal used for?

The primary use of Monel metal lies in its ability to withstand harsh environments, where traditional metals often fail. Its corrosion resistance is particularly noteworthy, allowing it to thrive in conditions where other alloys would quickly deteriorate. This characteristic has led to its widespread use in the chemical processing industry, where acids and other corrosive substances are commonly used.

In the realm of marine engineering, Monel finds its niche as a material that can stand up to the relentless corrosion caused by saltwater. Its low corrosion rate in flowing seawater, coupled with its high strength, makes it an excellent choice for components such as centrifugal pump shafts that are constantly exposed to the harsh marine environment.

The aerospace and aviation industries also heavily rely on Monel. In these sectors, materials must not only be strong and corrosion-resistant but also able to withstand extreme temperatures. Monel metal fulfills these requirements, making it suitable for components like gas turbine blades and engine disks that operate in high-temperature environments.

Moreover, Monel metal’s ductility and formability allow it to be shaped into intricate designs, further broadening its application range. This versatility has led to its use in the manufacture of jewelry and decorative items, where its silvery appearance and durability are highly valued.

It’s worth noting that the specific composition of Monel can vary depending on the intended application. Different ratios of nickel, copper, iron, and manganese can be used to tailor the alloy’s properties to meet specific requirements. For instance, increasing the nickel content can enhance the alloy’s corrosion resistance, while adding iron and manganese can improve its mechanical strength.

In addition to its functional uses, Monel is also prized for its ability to maintain its appearance over time. Unlike some other metals, which may oxidize or discolor with exposure to the elements, Monel metal retains its original finish, making it a long-lasting choice for both industrial and decorative applications.

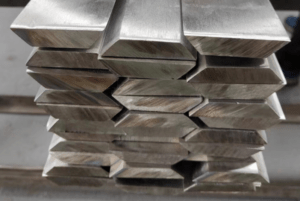

The manufacturing process of Monel is also noteworthy. It involves carefully controlled melting and casting techniques to ensure a uniform and defect-free alloy. This attention to detail during production is crucial in ensuring that the final product meets the strict quality standards required for its various applications.

The environmental impact of Monel metal is also an important consideration. While its corrosion resistance and durability mean that it has a long service life, the recycling and disposal of Monel metal scrap must be done responsibly to minimize any potential environmental harm. Many recycling facilities are now capable of processing Monel metal scrap, ensuring that this valuable resource is not wasted.

Conclusion

In conclusion, Monel metal is a versatile and durable alloy that finds widespread use in various industries due to its exceptional corrosion resistance and mechanical properties. Its ability to withstand extreme conditions and maintain its appearance over time make it a valuable material for both functional and decorative applications. As technology continues to advance, the uses for Monel are sure to expand, further solidify its position as a key material in the modern world.

Thank you for reading our article and we hope it can help you to have a better understanding of the uses of Monel metal. If you are looking for Monel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality Monel alloy products such as Monel 400 and Monel K500 at a very competitive price.